- Home

- VEICHI News

- VEICHI Showcases Innovative Solutions for High-End CNC Machine Tools at CIMT 2025

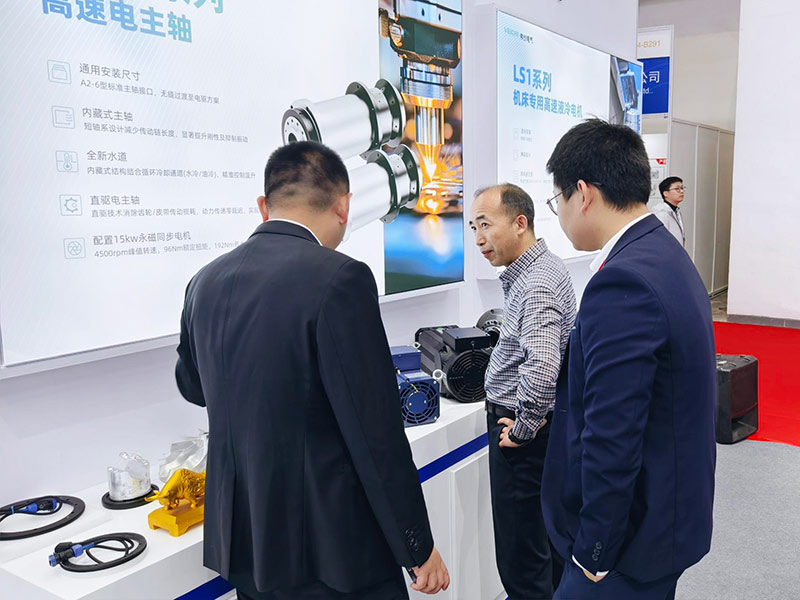

On April 21, VEICHI made a striking appearance at the China International Machine Tool Show (CIMT 2025), held at the China International Exhibition Center (Shunyi Hall) in Beijing. As a leading electrical equipment manufacturer, VEICHI presented its self-developed high-end CNC machine tool products and solutions, earning widespread recognition for its advanced technological capabilities and innovative applications.

Innovative Product Portfolio Highlights Core Competitiveness

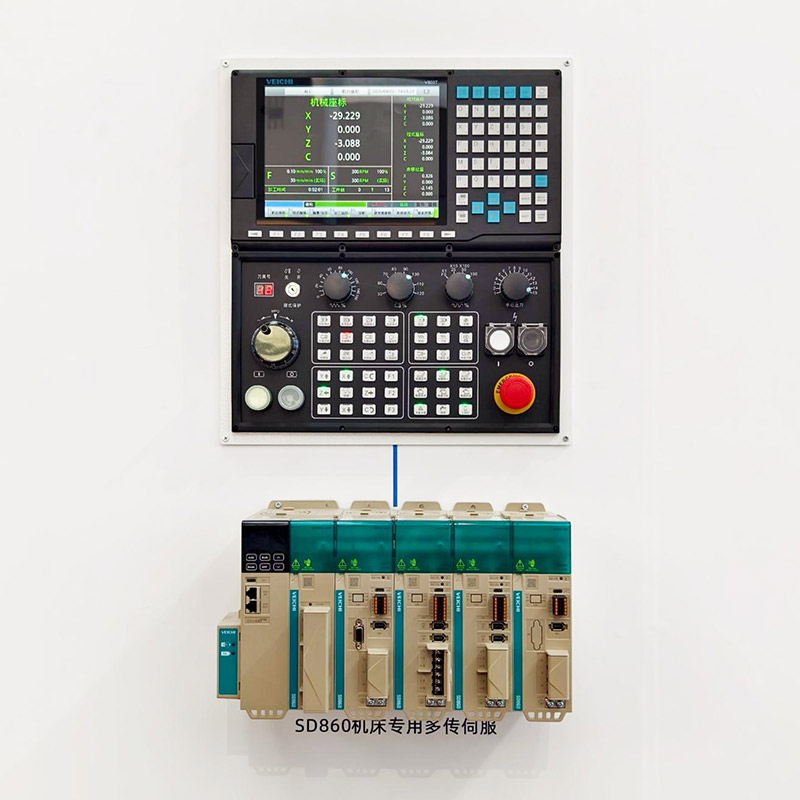

VEICHI showcased its comprehensive product matrix for the machine tool industry: V800T/V800M series CNC system is equipped with a robust secondary development platform to enhance machining precision and efficiency; The SD860 series general multi-drive Servo System delivers high-precision control and dynamic response for complex working conditions; HCVT series high-speed motorized spindle ensures stable performance with ultra-high rotational speeds; and LS1 series special liquid-cooled motor features innovative cooling technology for sustained high-efficiency operation. These cutting-edge products attracted extensive attention from industry professionals, sparking in-depth technical discussions.

Full-Scenario Solutions Drive Industry Advancement

To demonstrate solution performance intuitively, VEICHI highlighted its electrical control systems for turning-milling compound, drilling-tapping centers, machining centers, and 5-axis simultaneous machining through immersive 3D demonstrations and expert commentary. These solutions deliver high stability and strong compatibility, providing tailored intelligent manufacturing support to boost production efficiency in the machine tool industry.

1. Turning-Milling Compound

This solution supports up to 6-path 32-axis control, integrating a bus-type I/O system with SD860 multi-drive servo system to achieve high-precision interpolation for advanced turning-milling operations. The SD860 series features high power density for space-saving installation, common DC bus design for energy efficiency, and comprehensive debugging software for simplified setup. It is equipped with rechargeable batteries to eliminate frequent replacements, and supports flexible configurations with single-axis/dual-axis servo systems and single-spindle servo system as needed.

2. Drilling and Tapping Center

This solution enables rapid tool change and high-speed spindle positioning, featuring automatic tool length measurement, pre-acceleration/deceleration control, single-block preview function, multi-block fitting technology, and CAD/CAM program smoothing functionality, meeting demands for high speed, precision, and operational stability.

3. Machining Center

This solution enables high-speed, high-precision cutting with full process detail reproduction. It incorporates path pre-smoothing, pre-acceleration/deceleration control, and multi-block fitting technology, while supporting curve speed clamping functionality and compatibility with various mainstream tool magazines.

4. Five-axis Simultaneous Machining

This solution integrates multi-axis coordination to enhance machining flexibility for complex surface processing. Through tool tip following control, feature plane control, and tool axis vector smoothing, it significantly improves machining accuracy while broadening application scope.

At this exhibition, VEICHI comprehensively demonstrated its technical expertise and extensive industry experience in high-end CNC machine tools. Moving forward, VEICHI will remain focused on industry trends, deeply explore customer needs, and continually launch more competitive innovative products and integrated solutions to provide stronger support for "Intelligent Manufacturing in China".

April 21–26

Visit VEICHI’s Booth E4-B202 to explore more innovations!

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message