From December 17 to 19, 2025, the highly anticipated “CIAA25 Motion Control/Direct Drive Technology Industry Development Summit Forum and Awards Ceremony” was grandly held in Shenzhen. VEICHI’s VG700 series book-type industrial intelligent controller stood out for its innovative applications and outstanding performance in intelligent manufacturing, earning the “CMCD 2025 Industry Application Award in Motion Control.”

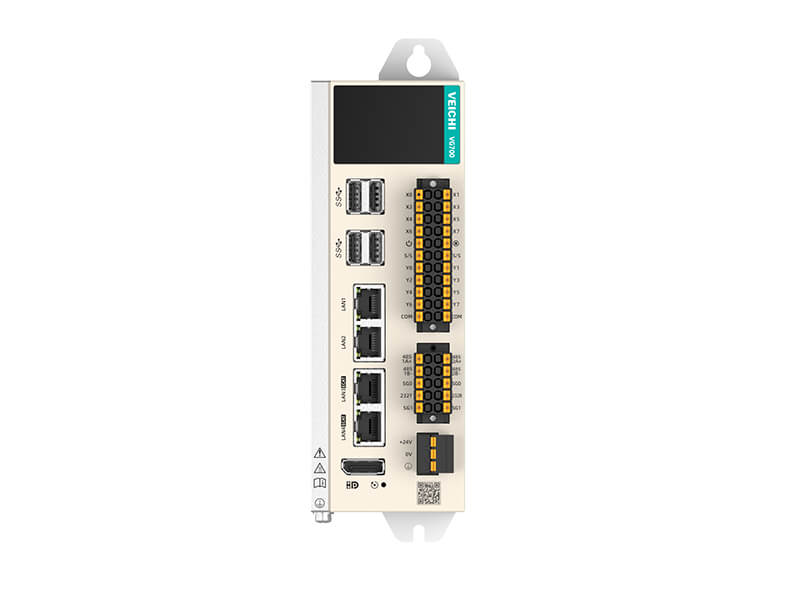

New-Gen Intelligent Control — Technical Advantages of the VG700 Series

Based on the Intel X86 processor platform, the VG700 series complies with PLCopen specifications and IEC 61131-3 international standards. Supporting multiple programming languages, it is a highly integrated, high-performance, book-type motion controller.

1

High-Speed Network Architecture: Ultra-Fast Communication, Precise Connectivity

- Real-time motion control: Dual EtherCAT buses as standard, supporting high-precision synchronous control of up to 256 axes.

- Intelligent data interaction: Dual Gigabit Ethernet ports support TCP, UDP, Modbus TCP master/slave, EtherNet/IP Scanner/Adapter, OPC UA Server, and more—seamlessly connecting shop-floor data with IT systems.

2

Highly Integrated Interface Design: Stable and Reliable

- High-precision motion interfaces: 8 channels of 200kHz high-speed pulse I/O with opto-isolation ensure high-speed, high-precision motion control.

- Rich expansion interfaces: 1×RS232 and 2×RS485 supporting Modbus and free protocols; integrated 4×USB 3.0 and DP display interface for easier debugging and expansion.

3

Intelligent Storage Protection: Secure Data, Efficient Operation

- Built-in 128 GB SSD and 8 GB memory, integrated with UPS power protection, ensuring zero data loss and stable system operation.

Successful Application in the Automotive Manufacturing Industry

Designed for automation scenarios demanding high speed, high precision, and high performance, the VG700 series is a reliable controller for industrial upgrading. In automotive panel filter production equipment, it demonstrated outstanding performance in addressing complex patterns and stringent accuracy requirements.

- High-precision coordination: Multi-axis servo control via EtherCAT, combined with dedicated arc and linear algorithms, precisely executes complex glue-spraying trajectories composed of multiple curves.

- Flexible production: Supports parameterized graphics—leveraging standard graphic libraries or quickly customizing niche product patterns to meet diverse needs.

- Quality and efficiency gains: Significantly simplifies manual commissioning, improves product consistency, and boosts overall production efficiency.

This award represents strong industry recognition of VEICHI’s sustained technological focus and innovative applications. Looking ahead, VEICHI will continue to enhance its motion control portfolio, empowering digital and intelligent transformation with more precise, efficient, and intelligent solutions—working with partners to build a smarter manufacturing future.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message