- Home > Product > Industry-specific Drive > Drawing Machine > AC310-XL Special Inverter for Cable Industry

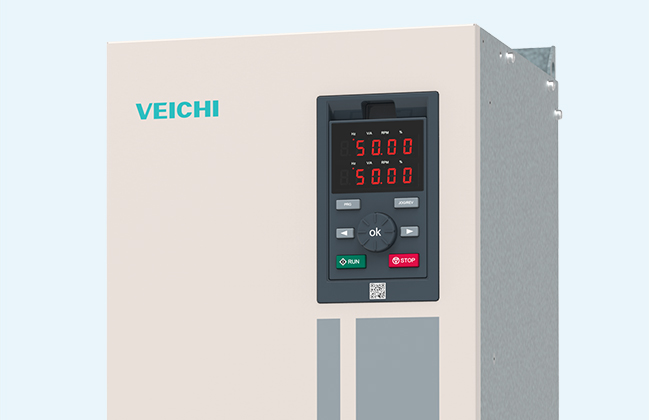

AC310-XL Special Inverter for Cable Industry

- High-performance vector general platform & brand-new motor control algorithm;

- Integrated PSAM & AM drive & comprehensive open-loop and closed-loop;

- Book design saves installation space;

- Up-down straight air-duct design & DC fan cooling;

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

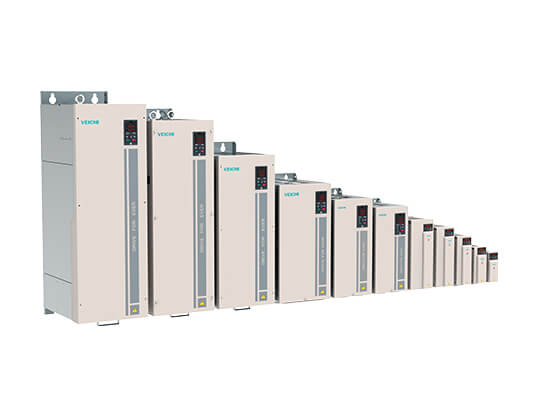

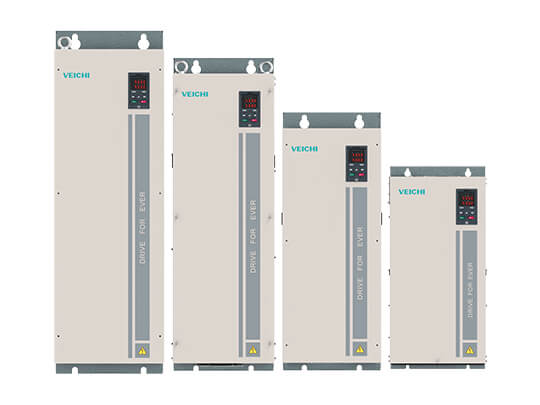

AC310-XL Special Inverter Overview

AC310-XL special frequency converter for cable industry is a product continuously developed on the high-performance vector technology platform of VEICHI. It adopts field-oriented vector control technology, compatible with asynchronous and synchronous motor control. Moreover, under the premise of high performance and high reliability, the components are arranged reasonably to realize the book-style narrow body design. The design has strengthened customer ease of use and industry professionalism, and is equipped with a wealth of expansion interfaces.

1. Narrow book design, beautiful, convenient and space-saving installation cabinet.

2. Independent air duct design, the fan can be disassembled freely, and the heat dissipation is good.

3. The PCB is all thickened with three anti-paint treatment, which is more reliable.

4. High seismic design, easy to deal with the vibration of the wire drawing machine.

5. Abundant expansion capabilities, IO card, communication card, GPRS, PG card, etc.

6. Can be applied to a variety of cable equipment.

AC310-XL has a variety of cable equipment applications, smart macro selection one-key setting

Feature rich

1. Independent calculation of cable length, weight, current line speed, etc., without peripheral equipment.

2. The disconnection detection function is comprehensive, and the software can automatically judge the system disconnection or the proximity switch input disconnection, and the extension time can be set freely.

3. Brake signal output, you can freely set the brake action frequency and brake maintenance time.

4. The smooth start function ensures that the material tension quickly reaches stability during start-up.

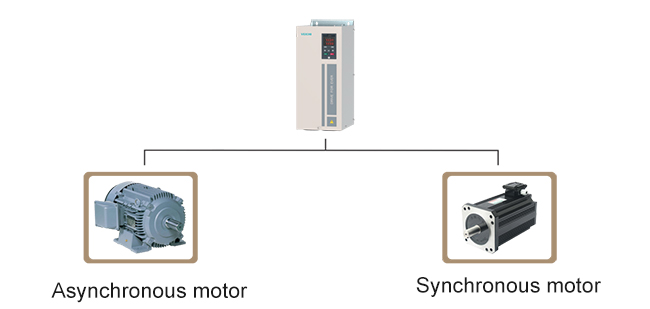

Synchronous and asynchronous integrated drive

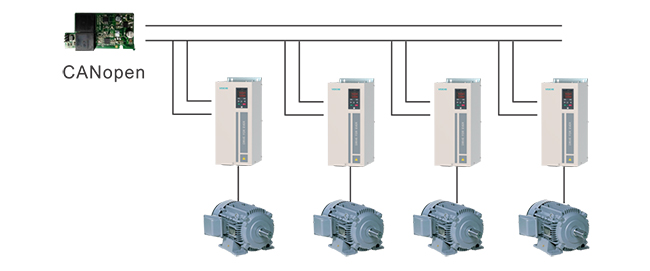

Compatible with CANopen bus interface and supports modularization of distributed slave stations

Standard Modbus communication, support multiple sets of data interaction between master and slave system, simplify field wiring

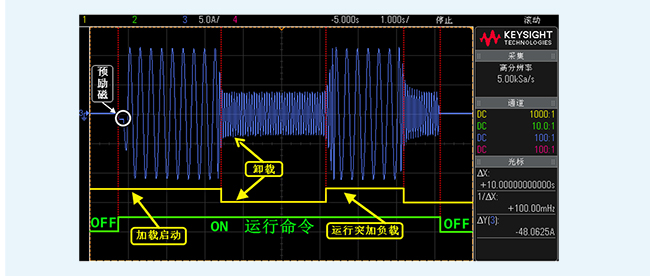

Superior performance

Using high-performance vector control technology, low-frequency torque is large, load response is fast, open loop 0.5Hz 150% torque output. Closed loop 0Hz200% torque output.

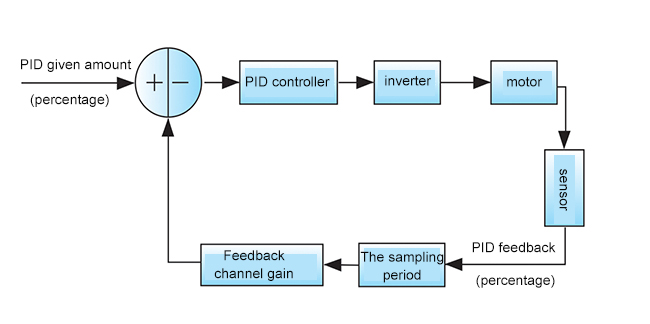

The unique PID control algorithm quickly responds to the tension and reaches a stable state instantaneously. The tension control algorithm is integrated, and no external control circuit is required.

Industrial Applications for AC310-XL Special Inverter

Applications:Water tank wire drawing machine, straight wire drawing machine, pulley type wire drawing machine, non-swing rod wire drawing machine, power pay-off, tension frame winding, etc.

Specifications

| Power range | 750 W-710,000 W |

|---|

| Voltage and frequency | Three-phase 380V 50/60HZ |

|---|---|

| Allowable fluctuation range | Voltage: ±15%; frequency fluctuation: ±5% Distortion rate: meet the requirements of IEC 61800-2 |

| Closing surge current | Less than rated current |

| Power factor | ≥0.94(With DC reactor) |

| Inverter efficiency | ≥96% |

| The output voltage | Output under rated conditions: 3-phase, 0~input voltage, error less than 5% |

|---|---|

| Output frequency range | Maximum output frequency: 320HZ |

| Output frequency accuracy | ±0.1% |

| Overload capacity | 150% rated current 60s, 180% rated current 5s, maximum 2.5 times |

| Modulation | SVPWM |

| Carrier frequency range | 2.0~8.0kHz(Model determination) |

| Digital setting | maximum speed×±0.01% |

| Analog setting | maximum frequency×±0.2% |

| Speed resolution | Digital setting: 1rpm Analog setting: maximum speed×0.05% |

| Acceleration and deceleration curve | Linear acceleration and deceleration, S curve acceleration and deceleration |

| Automatic energy saving operation | According to the load condition, the output voltage is automatically optimized to realize energy-saving operation |

| Automatic current limit | Automatically limit the current during operation to prevent frequent over-current fault trips |

| Standard function | Oil pressure closed loop control, speed control, RS485, analog output |

| Speed setting channel | Keyboard digital setting, analog voltage/current terminal AI1, analog voltage/current terminal AI2, analog voltage/current terminal P-AI, communication setting and multi-channel terminal selection, combination of main and auxiliary channels. |

| Feedback input channel | Voltage/current terminal AI1, voltage/current terminal AI2, voltage/current terminal P-AI, communication setting |

| Run command channel | Operation panel setting, external terminal setting, communication setting |

| Input command signal | Start, stop, forward and reverse rotation, jog, multi-speed, free stop, reset, acceleration and deceleration time selection, speed setting channel selection, external fault alarm |

| External output signal | 2 relay outputs; 1 transistor output; 2 analog outputs, voltage output range: 0~10V/0~10V, current output range: 0~20mA/0~20mA |

| Protective function | Overvoltage, undervoltage, current limit, overcurrent, overload, overheating, data protection |

|---|

| LED display | Single line 5-digit digital tube display: Can monitor 1 status |

|---|---|

| Status monitoring | Pressure command, pressure feedback, speed setting, speed feedback, flow command, output current, output voltage, output torque, output power, bus voltage, module temperature, motor temperature, input terminal X connected state, output terminal Y connected Status etc. |

| Error alarm | Self-learning abnormality, sensor feedback disconnection, motor overheating, driver overheating, encoder failure, communication failure, overvoltage, undervoltage, overcurrent, short circuit,Phase loss, overload, stall, current limit, data protection damaged, current fault operating status, historical fault. |

| Installation site | Indoor, the altitude is not more than 1000m, no corrosive gas and direct sunlight |

|---|---|

| Temperature and humidity | From -10°C to +40°C 5% ~ 95%RH(No condensation) |

| vibration | Less than 0.5g |

| Storage temperature | From -25℃ to +60℃ |

| Installation method | Wall-mounted, vertical cabinet |

| Protection level | IP20 |

| Cooling method | Forced air cooling, liquid cooling |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message