- Home > Product > Electric Drive > Medium Voltage Drives > ACH200 Series Medium Voltage AC Drive

ACH200 Series Medium Voltage AC Drive

- High-performance control platform.

- Start with high torque and low frequency.

- Excellent low frequency control performance.

- Stall protection for full frequency.

- Advanced interfere-free switching technology.

- Remote diagnosis.

- Ride-through design between low and high voltage.

- Perfect harmonic-free design.

- Multiple unit bypass methods.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

ACH200 Medium Voltage AC Drive Overview

ACH200 series products are the third generation of high-performance high-voltage vector-type AC drive made by VEICHI Electric on years of technical accumulation and in-depth market research and demand analysis, which adopts mature power unit series technology, DSP+FPGA dual core control, vector control algorithm, to deliver high control accuracy, fast dynamic response, large low frequency output torque etc. It is widely used in fans, pumps, compressors, belt machines, ball millscrushers and other load occasions, providing the drive core for energy saving and emission reduction to meet the diversified needs of industrial enterprises.

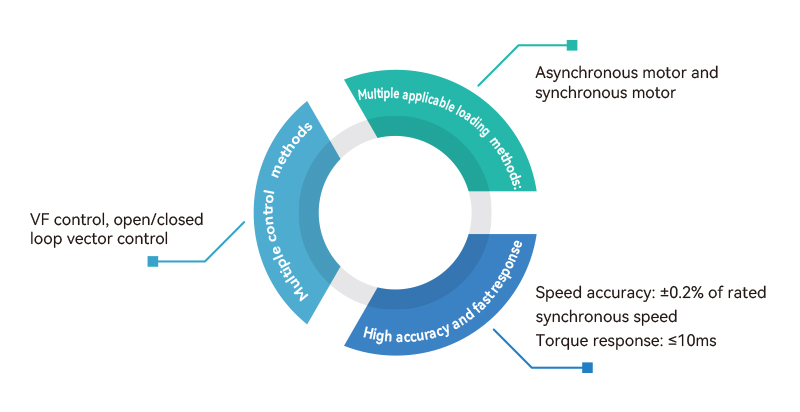

High-performance control platform

DSP+FPGA dual-chip control structure, control algorithms implemented by DSP, and external signals such as IO, bus and encoder processed by FPGA in parallel. High-speed and high-precision loop control ensures the excellent dynamic response capability and control accuracy.

Start with high torque and low frequency

Open-loop vector control: 0.5Hz 150% starting torque.

Closed-loop vector control: 0Hz 200% starting torque.

200% rated torque output at 0Hz for IPM motors under open-loop control by highfrequency signal injection.

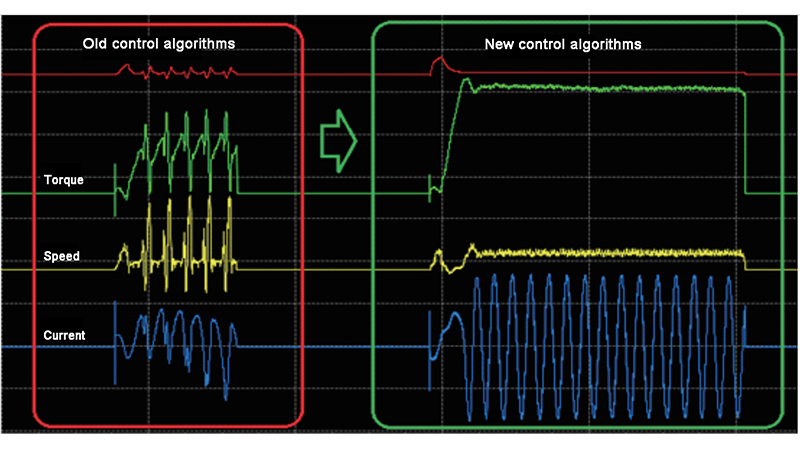

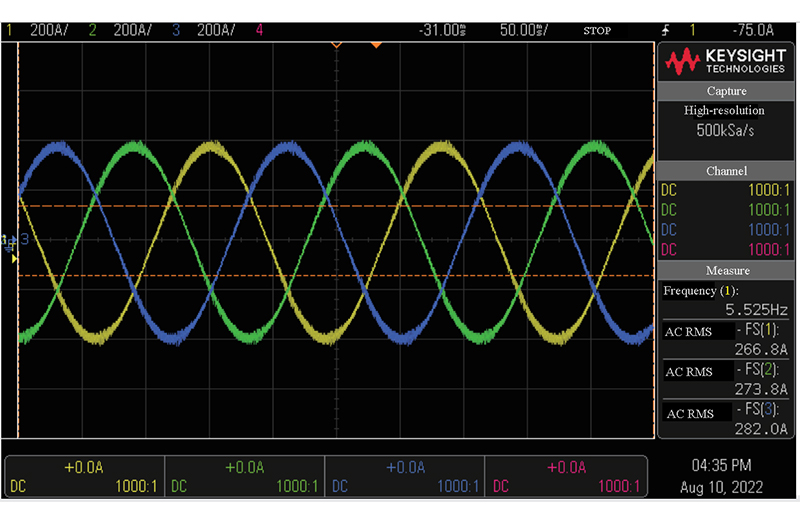

Excellent low frequency control performance

Dead-time compensation technology

Current waveform is nearly sine wave at low frequency.

Low-frequency oscillation suppression algorithm

Motor resonance will not be caused at low frequency.

Stall protection for full frequency

Track rotational speed accurately regardless of the motor speed states. (forward, reverse, still).

The whole process from starting to targeted state can be completed in shorter than 200ms with fast response.

Remanent voltage is larger at shundown of large inertia equipment, so its remanent and phase can be estimated after restart, and then enter rotary preexcitation and acceleration.

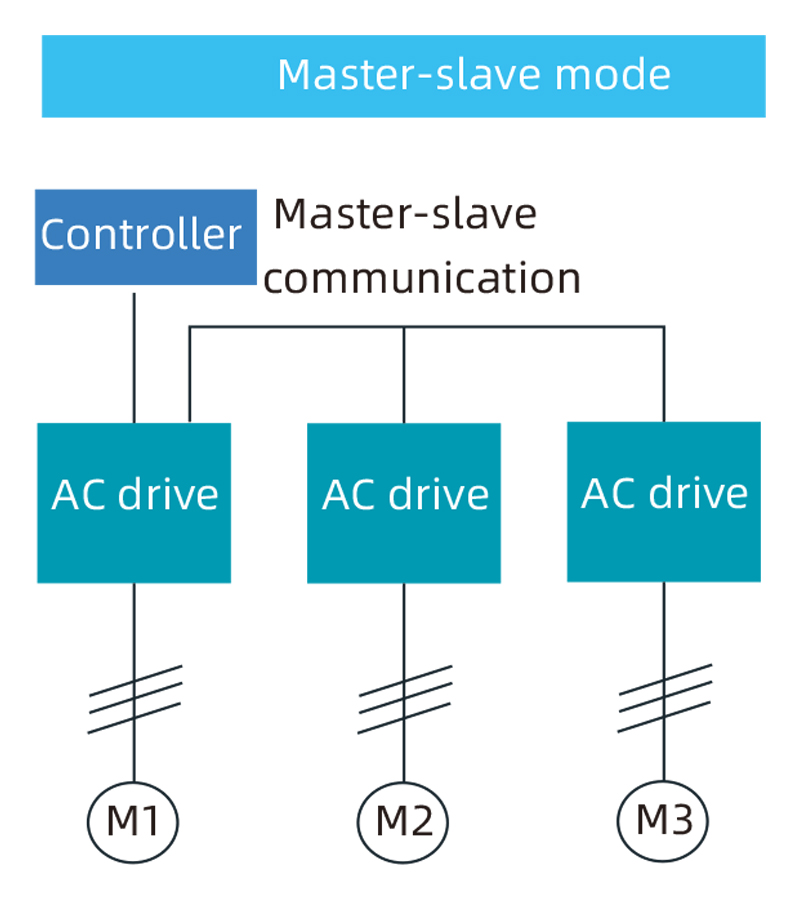

Master-slave control technology

CAN or fiber optic communication are adopted to ensure real-time communication and output consistency among multiple machines regardless of mechanical load and fluid load.

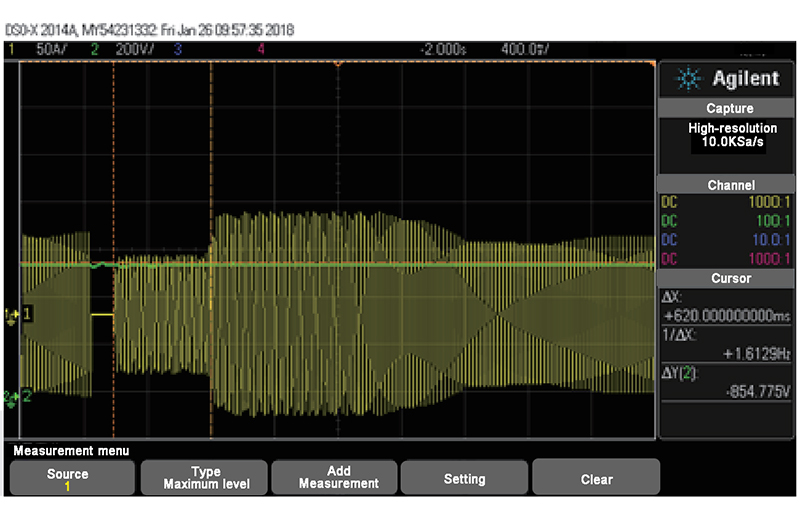

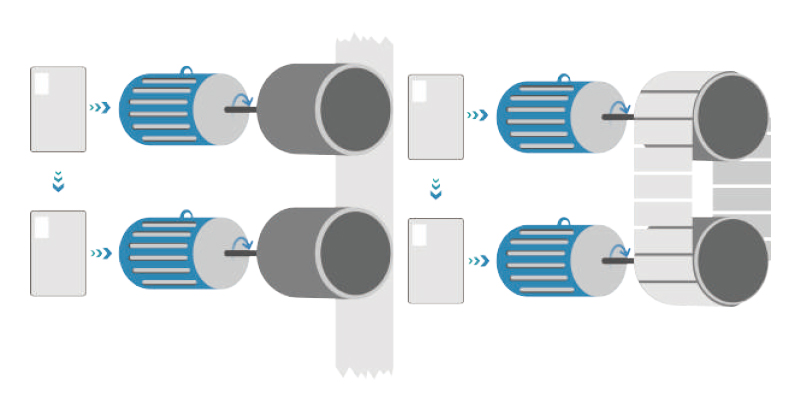

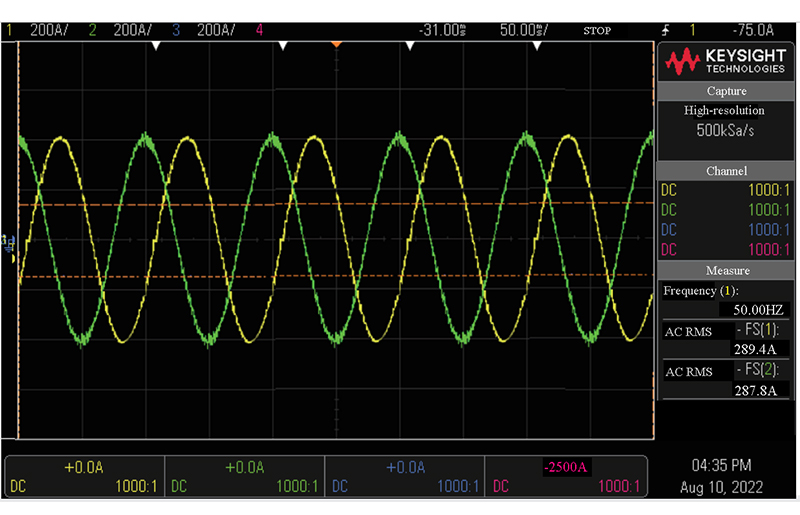

Advanced interfere-free switching technology

Phase-locked technology enables motor to start and run without interfere between power frequency and variable frequency, so it’s suitable for switching between multi-gear water pumps. The impact current of the switching process does not exceed 1.5 times of the rated motor current.

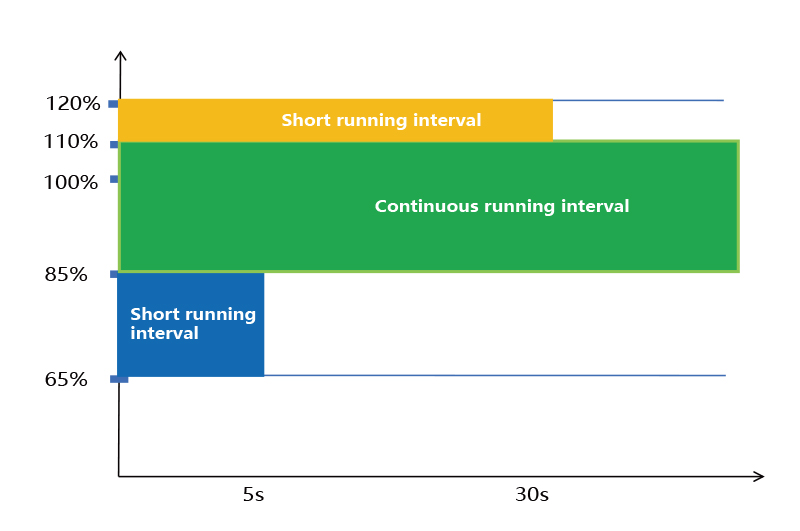

Ride-through design between low and high voltage

High adaptability to power grid fluctuations

85%-110% full-load output.

65%-85% derated output.

110%-120% derated output.

Motor nonstop during instantaneous power cut for long running

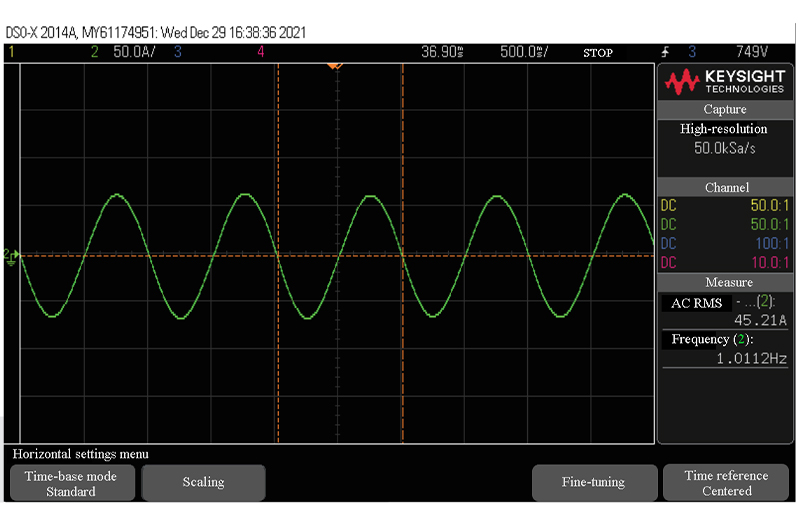

Perfect harmonic-free design

Multi-phase shift rectification technology on the input side

Grid-side THD value smaller than 2%.

Multi-level technology on the output side

Motor-side THD value smaller than 2%.

Multiple unit bypass methods

Parallel symmetric bypass.

Neutral offset bypass.

Standard with IGBT electronic bypass and optional with relay mechanical bypass.

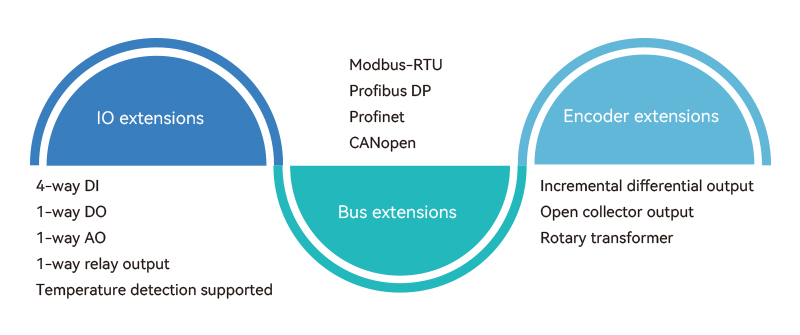

Multiple extension modes supported

Functional extensions according to actual requirements including IO extension, bus extension, encoder extension, etc,.

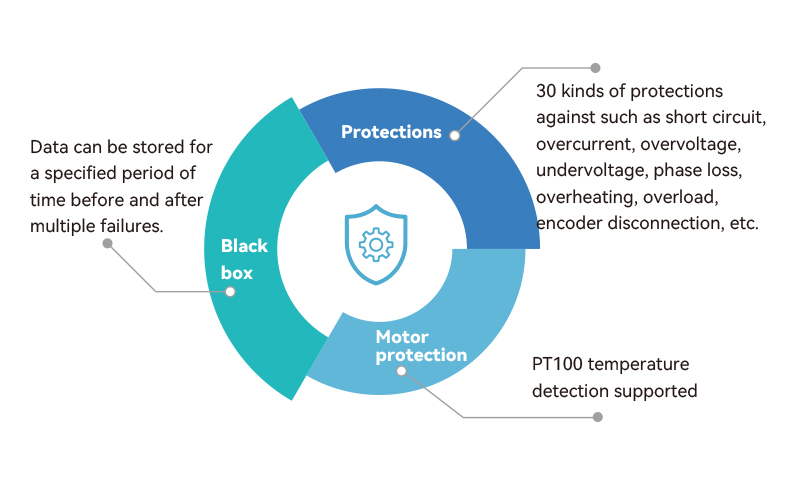

Multiple and comprehensive protections

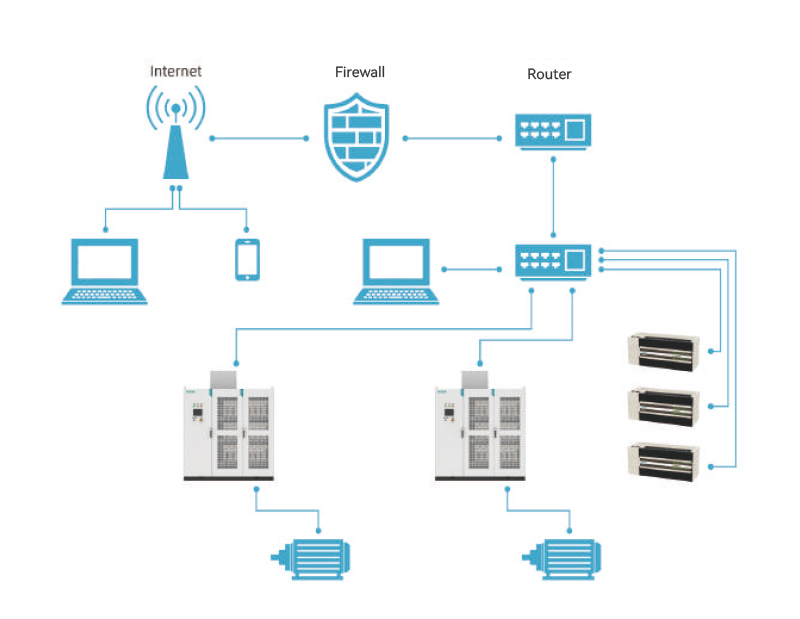

Remote diagnosis

Remote diagnosis is supported. After being authorized by clients, Veichi staff can check fault records, system parameters and running data to locate faults quickly, improving processes and efficiency on the remote server on the client’s side via VPN.

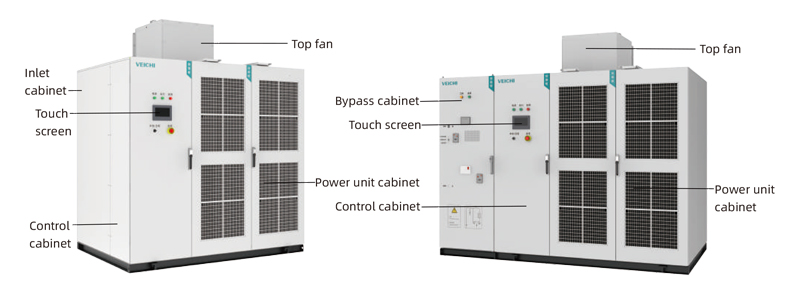

Cabinet Structure

ACH200 Series Medium Voltage AC Drive Video

Every ACH200 variable frequency drive is built with precision, innovation, and dedication to quality. From SMT and PCBA production, automated testing, and adhesive processes, to power unit assembly and lab verification, each step reflects VEICHI’s uncompromising standards.

Our fully automated lines—featuring AGV material handling, automated thermal paste application, and rigorous functional testing—ensure consistency, reliability, and performance that our customers can trust. From production to final warehouse delivery, every ACH200 carries VEICHI’s commitment: professionalism, high quality, and sincere responsibility to our customers worldwide.

Industrial Applications for ACH200 Series Medium Voltage AC Drive

Metallurgy

Sintering main exhaust fans,converter dedusting fans, blast furnace blowers, sulphur dioxide blowers, circulating coolers, combustion fans, slag flushing pumps, phosphorus removal pumps, etc,.

Electricity

Water feeding pumps, condensate pumps, water circulating pumps, air feeders, induced draft fans, primary fans, secondary fans etc,.

Mines

Main fans, gas extraction pumps, compressors, belt machines, ball mills, crushers, etc,.

Oil and Gas

Oil transporting pumps, water injection pumps, compressors, other fans and pumps, etc,.

Chemistry

Oil transporting pumps, water injection pumps, compressors, booster pumps, etc,.

Building Materials

High-temperature fans at kiln end, exhaust fans at kiln head, coal mill fans, cement mill circulating fans, dust exhaust fans, ball mills, crushers, etc,.

Municipal Administration

Aeration blowers, water supply pumps, water feeding pumps, induced draft fans, air feeders, etc,.

Others

Wind tunnel test fans, shore power supplies, internal mixers etc,.

Specifications

| Voltage level | 3kV/3.3kV/6kV/6.6kV/10kV/11kV |

|---|---|

| Voltage fluctuation range | -15%~+10% |

| Voltage frequency | 50/60Hz;±5% |

| Power factor | ≥ 0.97(at full load) |

| System efficiency | ≥ 96%(at full load) |

| Current harmonics | ≤4% |

| Voltage range | 0~rated input voltage |

|---|---|

| Frequency range | 0~120Hz(customizable) |

| Current harmonics | ≤4% |

| Voltage range | Three-phase four-wire 380V,±10%,50/60Hz |

|---|---|

| Rated capacity | No lower than10kVA |

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message