- Home

- VEICHI News

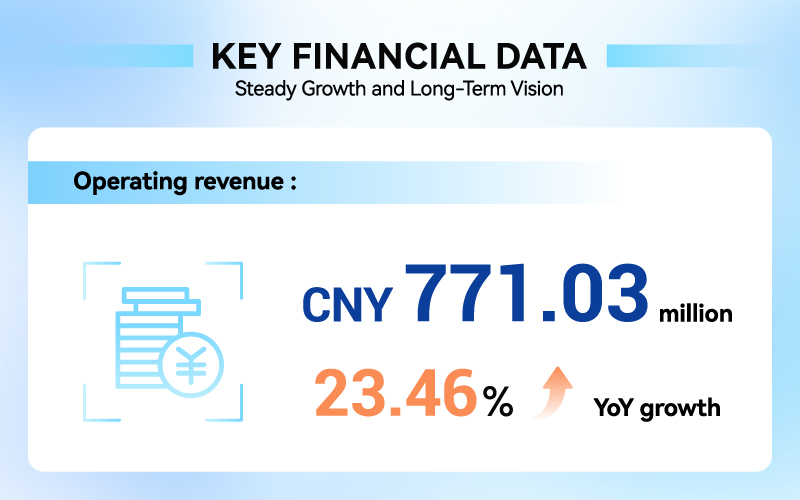

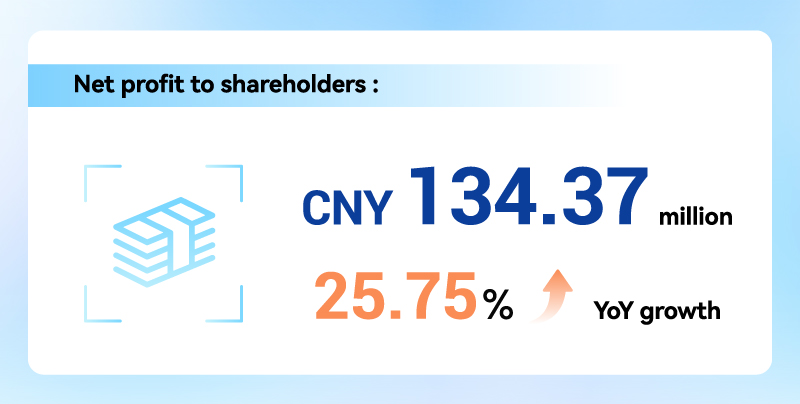

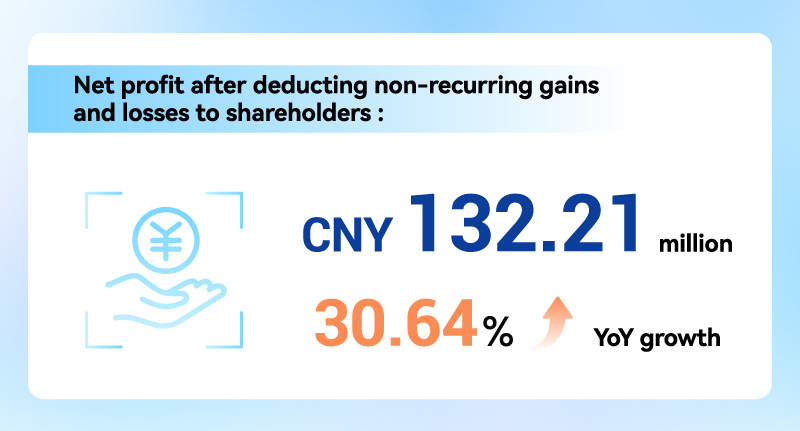

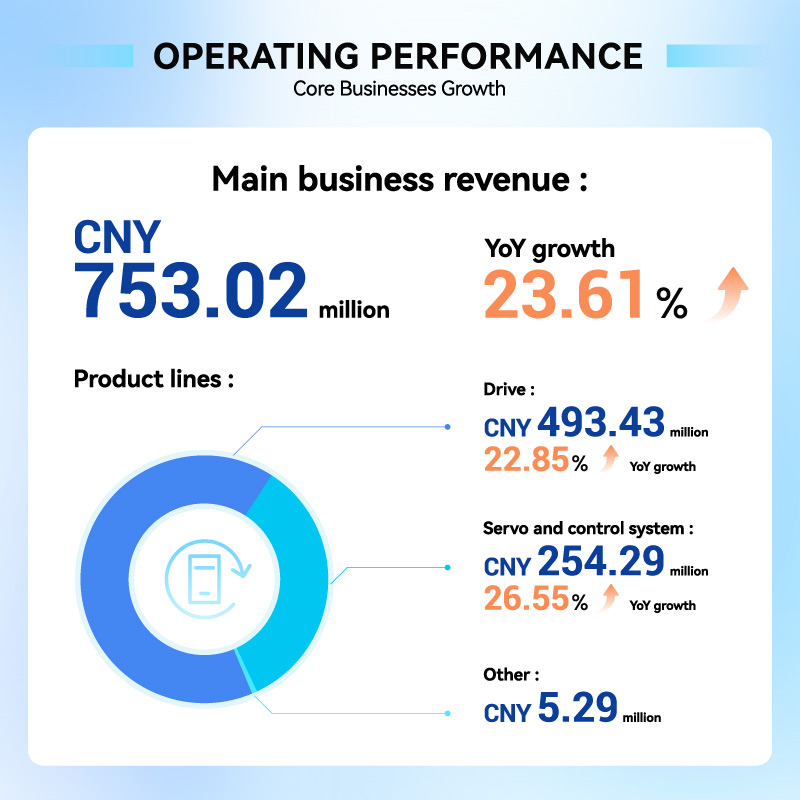

- Highlights of VEICHI 2024 Semi-annual Financial Report

Project Construction

Phase III intelligent manufacturing factory and digital transformation

In June 2024, the main structure of our integrated production and research innovation base reached completion in June 2024, aiming for an annual production capacity of one million units for drives, servo drives, and control systems, with operations set to commence in 2025.

Company Layout

Industrial AI machine vision sector

VEICHI is dedicated to the integration of industrial artificial intelligence with machine vision inspection. We offer an intelligent vision system centered around AI vision inspection modules, robotic intelligent control, industrial AI inspection software, and private cloud computing. This system is tailored for the final mile of AI in vertical industrial scenarios, aiding the intelligent manufacturing transformation in the manufacturing sector and bolstering the Company's overall capabilities.

Catering to the core testing requirements of the global 3C manufacturing industry, VEICHI delivers comprehensive AI precision testing solutions for high-precision sectors such as 3C, semiconductors, new energy, and automotive electronics.

Robotics sector

Building on our technological R&D strengths, VEICHI has successfully developed products like hollow cup motors, integrated servo wheels, and integrated servo machines. These are designed for applications in humanoid robot hands, various mobile robots, and robot joint parts, advancing the commercialization, scale, and industrialization of VEICHI's robotic technology applications.

High-end equipment

With extensive experience in variable frequency drive technology, VEICHI offers solutions for marine and offshore industries, including electric propulsion, shaft power generation, and hybrid DC networking with batteries/hydrogen fuel cells. We also provide comprehensive variable frequency drive solutions for the petroleum industry.

Additionally, VEICHI is driving the development of green ports through the widespread application of RTG oil-to-electricity technology and innovative advancements in RTG battery transition technology, reinforcing our unique competitive edge in high-end equipment.

Lithium battery testing and manufacturing

Leveraging our expertise in power electronics and lithium battery testing, VEICHI is committed to developing cutting-edge equipment for lithium battery testing, formation, and capacity grading. We have introduced efficient lithium battery testing power products and a suite of solutions for testing lithium battery cells, modules, and Packs with high accuracy and power density. Furthermore, we have launched a series of power products and solutions for lithium battery formation and capacity grading in the intelligent manufacturing process, establishing a distinctive advantage in the lithium battery charging and discharging power solutions sector.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message