Shaft Generator Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Shaft Generator Solution

In the context of accelerated green transformation in global shipping, facing increasingly stringent environmental regulations, rising fuel costs, and pressure to meet carbon-neutral targets, shaft-driven generator technology has become a key element in modern vessel energy management. Shaft generators are evolving from “optional energy-saving solutions” into “mandatory compliance equipment,” serving as core products driving sustainable development in the maritime industry.

Features and Benefits

Project Overview

As an enabler in electrical drive and industrial control, VEICHI Electric addresses industry needs by leveraging the innovative advantages of AC800 multi-machine drive technology to provide a liquid-cooled drive system solution for shaft generators, supporting green shipping with an efficient and energy-saving power system.

VEICHI's Solution

VEICHI Electric's AC800 shaft generator liquid-cooled drive system solution has been successfully applied to a 176,000 DWT bulk carrier shaft generator project, demonstrating excellent performance during shore-power commissioning and sea trials. This modular design innovatively integrates three core modules—shaft generator, AC800 liquid-cooled drive cabinet, and shipboard power network system—delivering a stable 850kW output to the network and supporting island operation mode. It significantly reduces auxiliary engine fuel consumption, achieving both economic and environmental benefits.

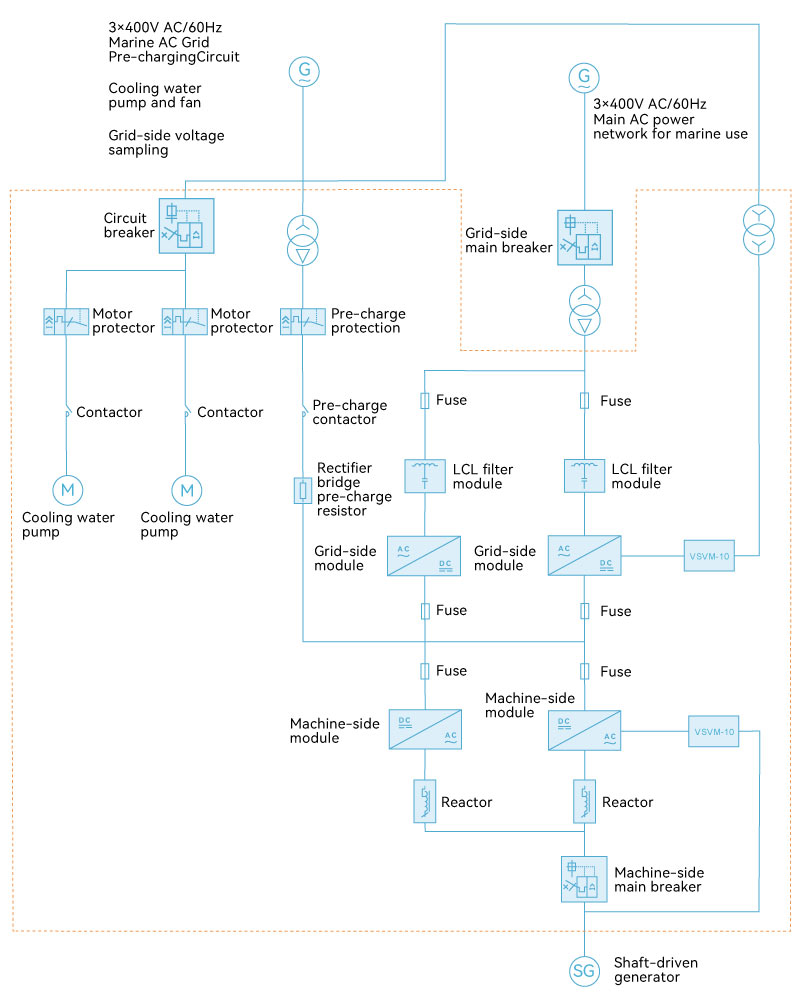

Core Architecture Analysis

1. Shaft Generator: Operates coaxially with the propeller shaft, supporting startup across a wide speed range of 40rpm~70rpm.

2. Intelligent Drive Cabinet: AC800 liquid-cooled shaft generator drive cabinet, integrating control cabinet, drive cabinet, and liquid-cooling cabinet in one.

3. Smart Power Network Platform: Shipboard power system covering diesel generator sets and intelligent load management system. (AC800 liquid-cooled shaft generator drive cabinet)(PMS cabinet and distribution cabinet)(Shaft generator)

Intelligent Operation Process

1. Pre-charge Safety: The drive system performs intelligent pre-charge; the machine-side module precisely controls breaker closing, maintaining bus voltage at DC 1020V.

2. Flexible Startup: Activate the grid-side module, which uses voltage ramp technology to achieve transformer pre-magnetization without impact.

3. Precise Synchronization: The grid-side module locks phase to synchronize with the ship network; once locked, it issues the closing command for seamless grid connection.

4. Intelligent Allocation: The Power Management System (PMS) can transfer load power to the shaft generator drive cabinet, enabling flexible power switching between the shaft generator and diesel generators.

5. Dynamic Balancing: Uses P–f droop control algorithm to ensure balanced power distribution when multiple sources are connected.

6. Energy-saving Mode: Intelligently identifies load demand and automatically switches to island operation to maximize energy-saving benefits.

System Topology

Solution Advantages

1. Outstanding Energy Efficiency

The shaft generator liquid-cooled drive cabinet can supply a rated 850kW to the ship network and is capable of stable operation in island mode at startup, reducing or even eliminating reliance on diesel generators and effectively lowering fuel costs.

2. Stable and Reliable Operation

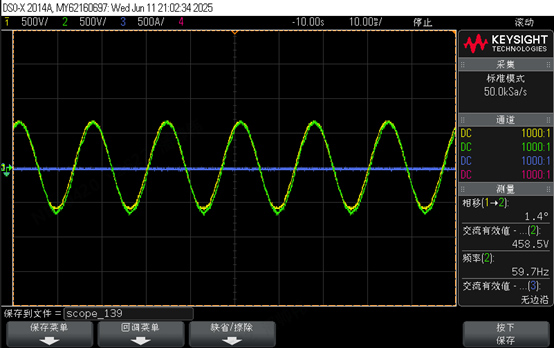

The shaft generator liquid-cooled drive system employs high-precision PLL synchronization technology (phase difference < 5°), optimizing voltage and frequency output, effectively preventing reverse power flow and ensuring continuous, stable operation under harsh conditions.

Synchronized waveforms with ship network: channel 1 (yellow) is ship network voltage; channel 2 (green) is drive cabinet output voltage via isolation transformer.

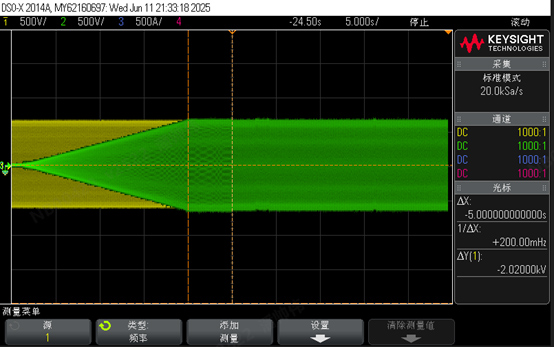

3. Innovative Pre-Magnetization Technology

An innovative voltage-ramp pre-magnetization scheme is used, omitting the transformer pre-magnetization circuit and effectively extending transformer service life.

Grid-side voltage ramp output: channel 1 (yellow) is ship network voltage; channel 2 (green) is drive cabinet output voltage via isolation transformer.

4. Smart Grid Compatibility

The AFE four-quadrant VFD module ensures that the shaft generator liquid-cooled drive output voltage and current harmonics comply with CCS standards (voltage

harmonics < 5%, current harmonics < 10%), ensuring normal operation of connected equipment.

Voltage and current harmonics up to the 16th order for a 247kW output of the shaft generator drive cabinet

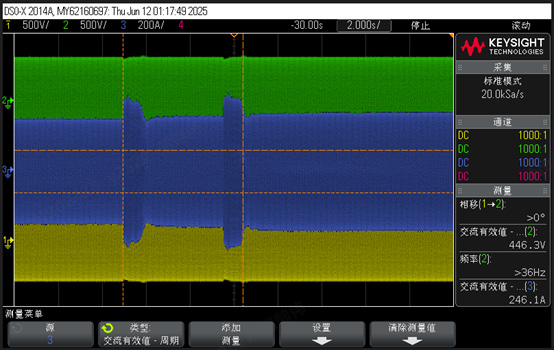

5. Multi-Condition Adaptability

The shaft generator liquid-cooled drive cabinet supports a wide main-shaft speed input range of 40rpm~80rpm and features impact and vibration resistance design to meet most sea conditions. When paralleled with diesel generators, it can start or stop ballast pumps and other high-power equipment to accommodate complex scenarios of sudden load changes on the ship network.

Voltage and current waveforms of the AC800 shaft generator liquid-cooled drive cabinet when starting a ballast pump

The successful application of the VEICHI AC800 shaft generator liquid-cooled drive system solution is the result of the VEICHI team’s close collaboration and coordination, fully demonstrating VEICHI Electric’s solid strength in the marine green power field. Going forward, VEICHI Electric will continue to deepen the “technology + scenario” innovation model by providing higher-quality scenario-based solutions, continuously promoting the shipping industry’s green low-carbon transformation and contributing VEICHI’s expertise and capabilities to achieve global carbon-neutral targets.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message