- Home > Product > Industry-specific Drive > Construction Machinery > CH610 Series Integrated Crane AC Drive

CH610 Series Integrated Crane AC Drive

- Highly integrated and compact design.

- Running status prompt.

- Simple installation and maintenance.

- Overload protection (integrated).

- IOT remote module (optional).

- Slow/inching operation.

- Energy-saving.

- Electronic soft limit protection (in closed loop).

- Wide operating voltage.

- Torque output error protection.

- Brake failure protection.

- Multiple macros.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

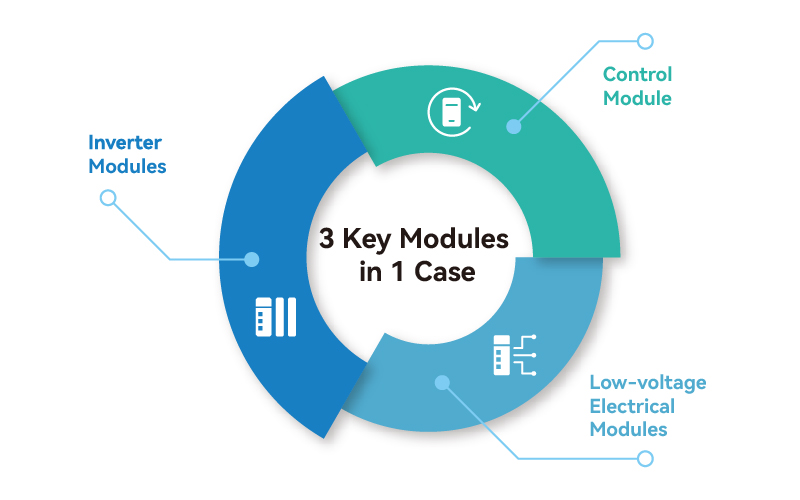

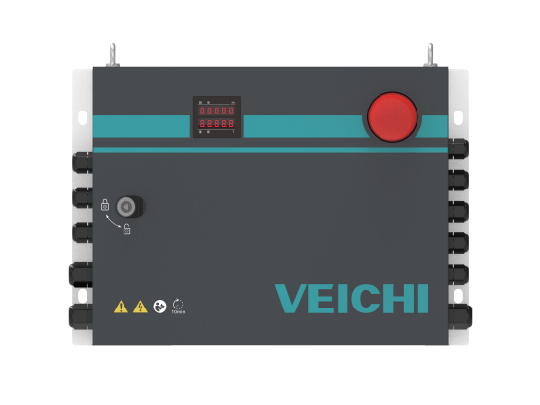

CH610 Integrated Crane AC drive Overview

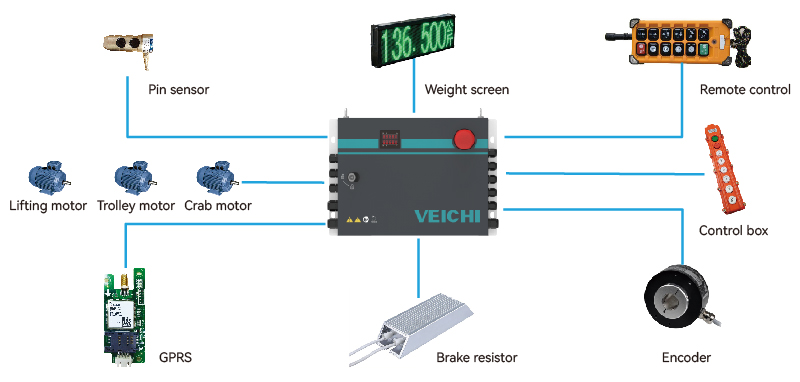

CH610 series AC drive is an “all-in-one” integrated product specially designed for cranes. It has three major inverter units, one logic control unit, one weight limiter and other low-voltage electrical appliances inside the housing. Based on years of industrial applica-tion experience and advanced driving algorithms, VEICHI provides customers with a complete set of high-performance, safe and reliable system solutions around this product. It can be used to drive the general-purpose lifting equipment including winches and hoists.

Basic Composition

Rich Functions

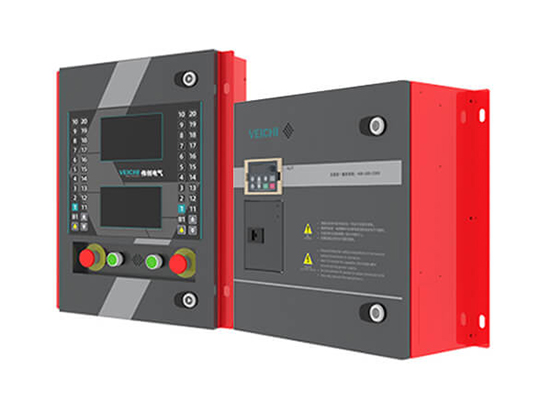

Highly integrated and compact design

It is a highly integrated design with components on PCB board to reduce quite a lot cables and wiring, and thus cabinet volume is reduced by 1/3 for higher product consistency and reliability.

Running status prompt

Keypad displays a status code when the unit is restricted or not in conformity to operating conditions for quick maintenance and overhaul.

Simple installation and maintenance

Quick-plug terminals save complicated installation and commissioning.

Overload protection (integrated)

The built-in lifting weight limiter ensures the safe operation of the equipment under the rated load and the LED display ports are reserved for real-time display of the current load.

IOT remote module (optional)

It can realize equipment positioning, remote monitoring, online debugging and maintenance, and equipment access management.

Slow/inching operation

It is suitable for high-precision alignment applications which requires less operator experience.

Energy-saving

The potential energy generated by the equipment is fully utilized in the common DC busbar solution, and only one braking resistor required for the system.

Electronic soft limit protection (in closed loop)

In the event of an upper/lower limit switch failure, the hook is still guaranteed against topping out to minimize the potential safety hazards.

Wide operating voltage

Reliable operation of the equipment is ensured within ±20% of the rated voltage.

Torque output error protection

The motor torque is monitored in real time during operation, and when insufficient motor torque is detected, the brake is immediately applied and the output is blocked to eliminate the potential safety hazards.

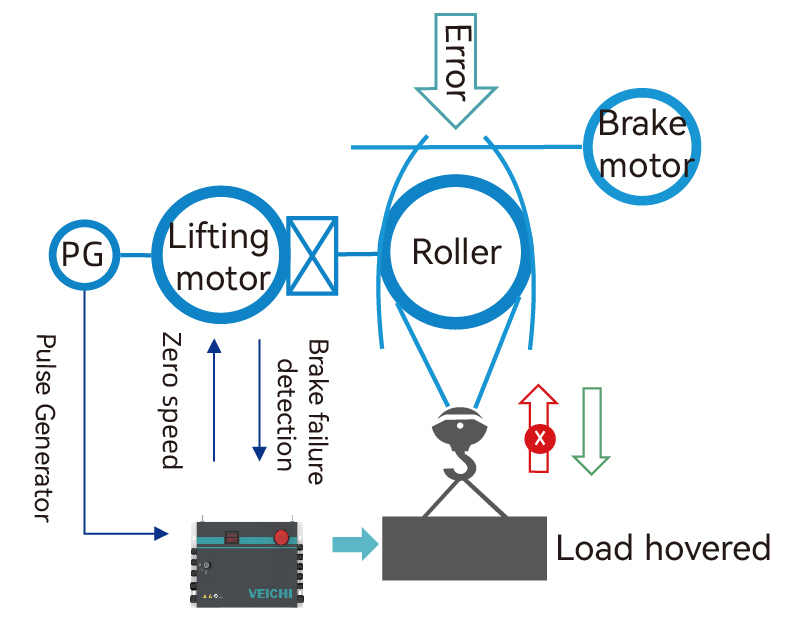

Brake failure protection

The system is equipped with double protection functions against brake signal abnormality and sticking and dragging brake.

Multiple macros

Built-in parameter groups of lifting, trolley and crab allow the users to choose macros according to the type of equipment mechanism to achieve one-key quick setup.

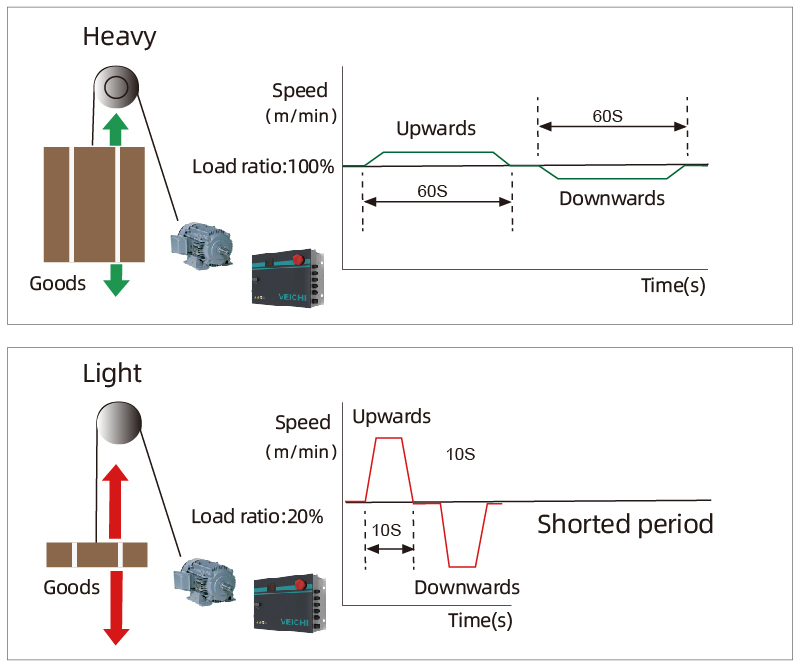

Efficient Operation

High speed for light loads while low speed for heavy loads

Constant power control(speed changing with load) is built in, so that in operation, the best running speed is calculated according to the current lifting weight, improving the speed by 1-2 times for higher efficiency of crane operation.

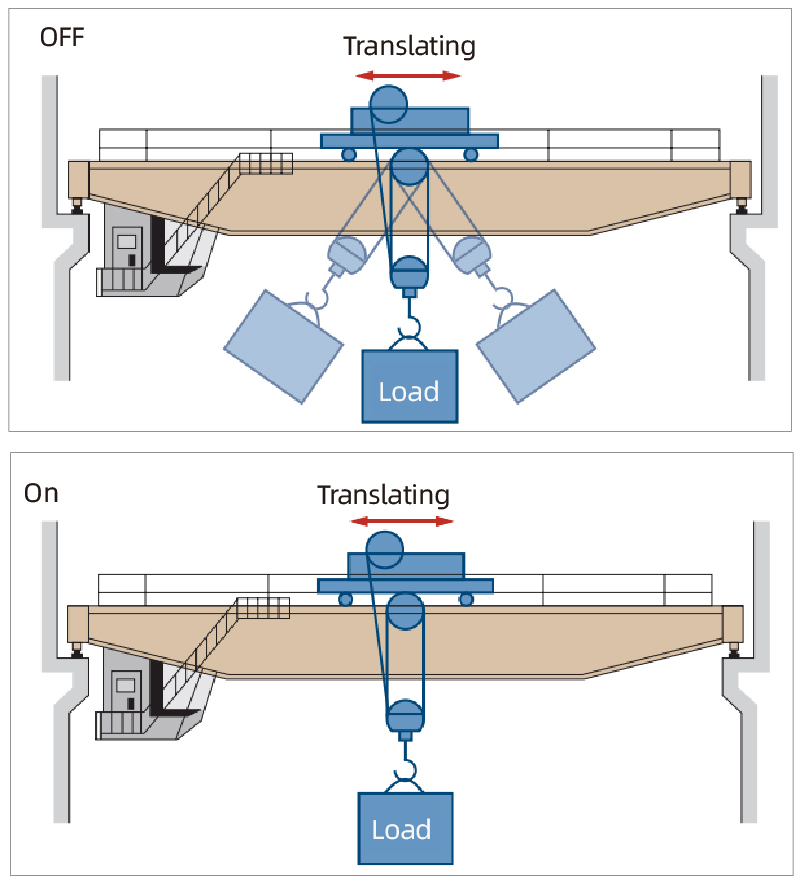

Anti-swing control

It is equipped with open/closed loop anti-swing control algorithm and features simple debugging and good adaptability to reduce hook sway caused by inertial shock during trolley/crab operation. And it suppresses the swinging amplitude of the goods when the crane is panning to ensure the efficiency of the material handling, and it improves the safety and stability of the operation. This function can be activated and deactivated using the selector switch.

Trustworthy safety

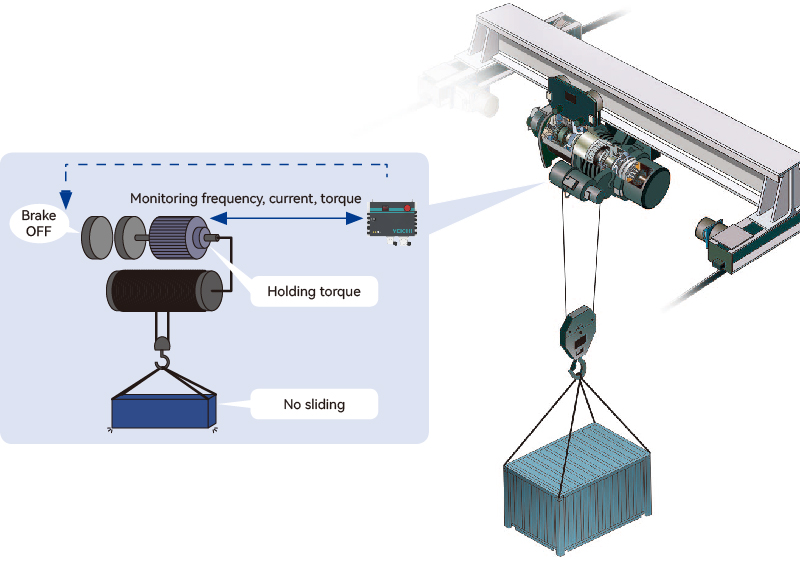

Zero-servo hovering anti-skidding protection(closed loop)

When there is an imminent risk of skidding due to brake failure, the system issues an alarm and makes the motor to hover or preforms controlled low-speed lowering to guarantee safety to the largest extent.

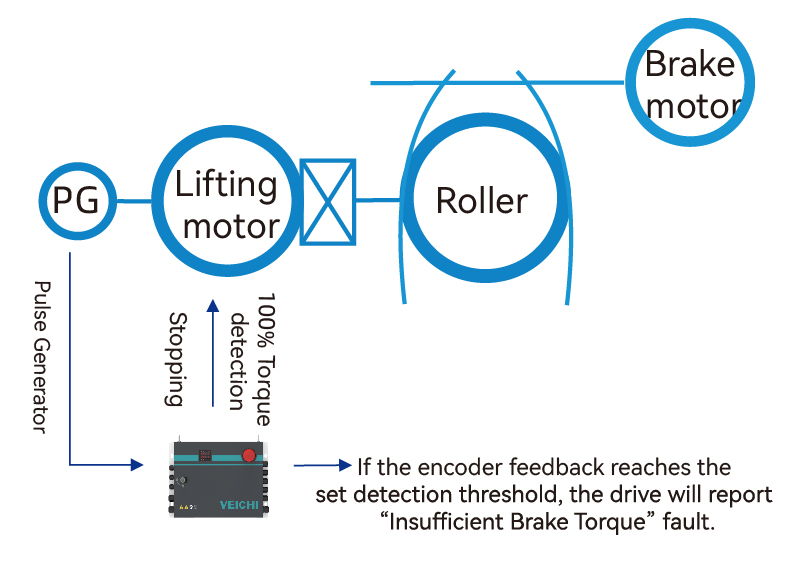

Braking torque detection

It regularly checks whether the brake torque meets the usage requirements, and when the insufficient brake torque is detected, the system will send alarms and stop the operation.

Dragging brake protection

Check the status of the brake contactor while the lifting mechanism is running. If the brake contactor is not engaged, the system will not continue to run to prevent excessive wear on the brake.

Brake control logic

The brake will act only when the two conditions of release/apply frequency and release/apply torque are satisfied at the same time, which ensures smooth starting and stopping without any hook slipping during lifting.

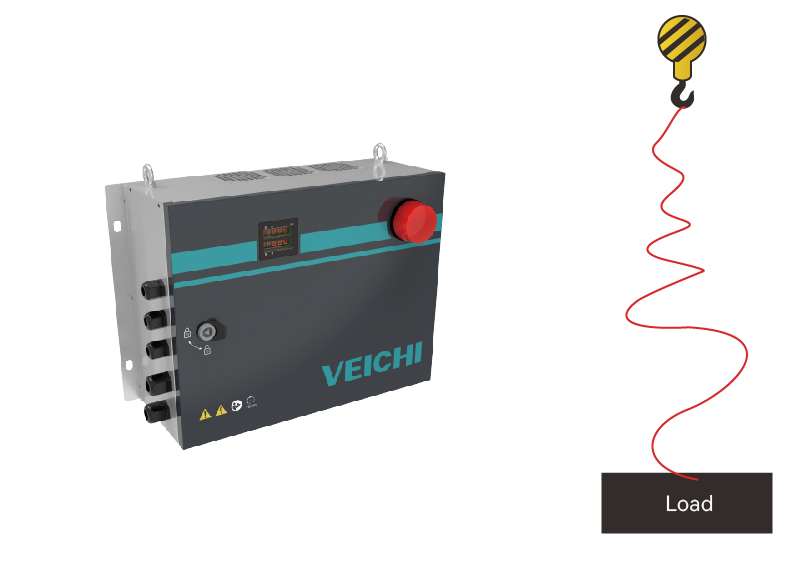

Rope protection

Automatic speed reduction and slow tightening will trigger during high-speed hoisting when the ropes are still slack to inhibit overstretching due to violent tension. And it can reduce mechanical shock damage and extend equipment life.

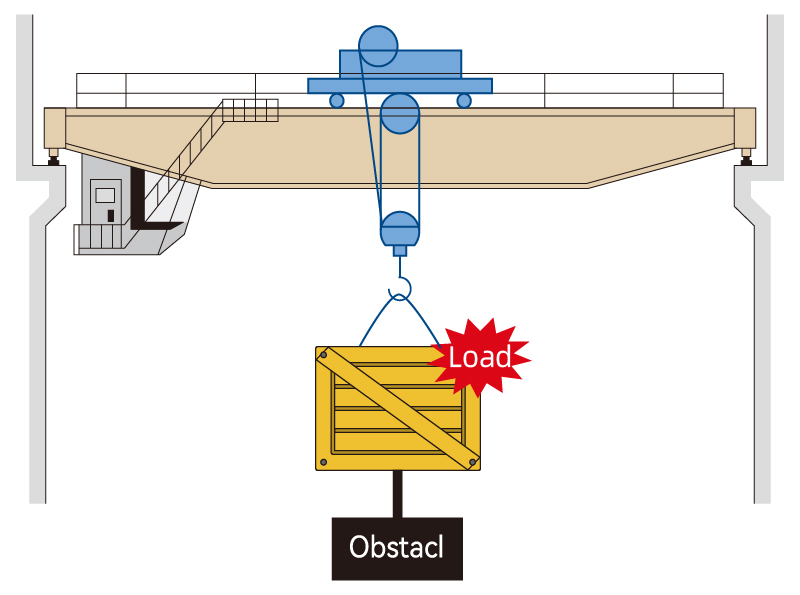

Anti-snag protection

If a sudden increase in load torque is detected during the lifting process (when the load is caught by a foreign object or an obstacle), an alarm is issued and operation is stopped to avoid further operation causing safety accidents.

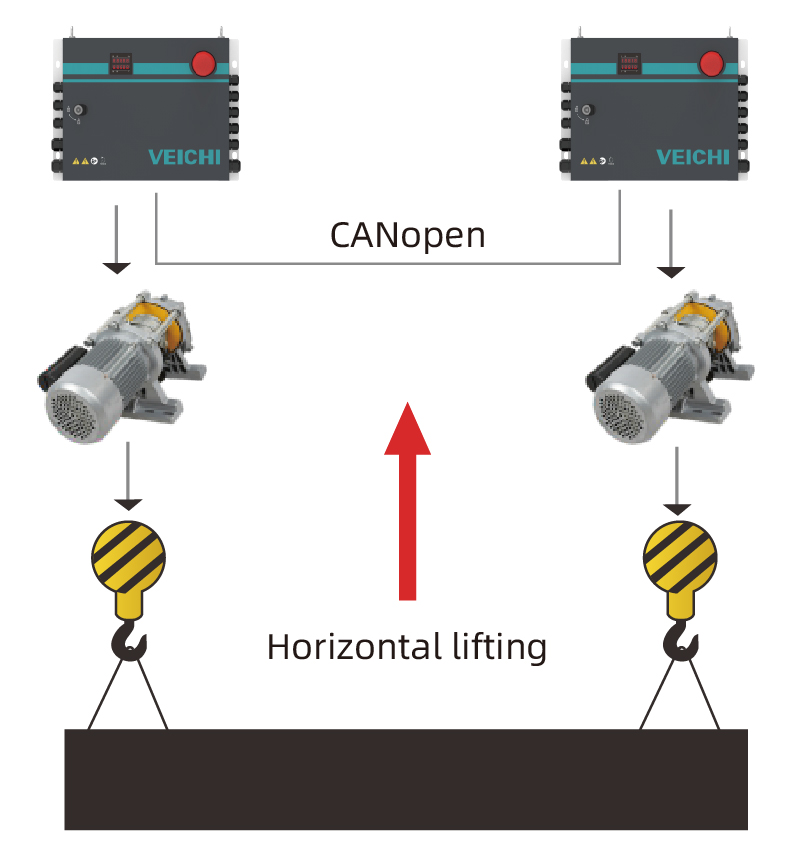

Sync control

When the two cranes are lifting up at the same time, CANopen bus communication can be used to realize both independent and sync control to ensure that lifting and traveling are performed synchronously. Flexible and easy operation through sync switches allows safer and more reliable operation.

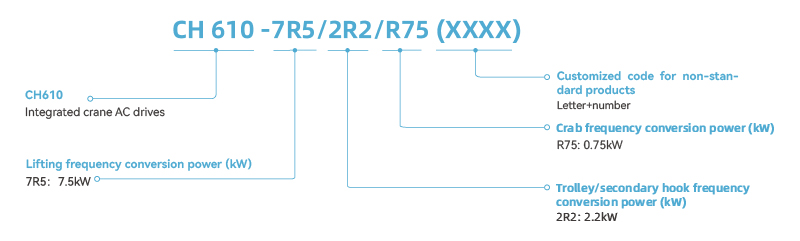

Naming Rules

LCD Remote Control (Optional)

Safe Solid Convenient

- The remote control transmitter is made of high-strength engineering plastics with all-round protection functions, and the OLED LCD screeen offers instant feedback and display of relevant command input and equip-ment operation data, together they support the CH610 series cranes integrated drive for easy and clear operations. Light and fresh transmitter appearance with IP65 housing against dust, high temperature and humidity. Silicone rubber covered edges resistant to shock and harsh environments.

- Auto frequency management with reliable wireless signal. Transmission multiple anti-interference design with digital hopping technology for non-interference operation in 433MHz~868MHz.

- 8 keys for double-speed control + password lock, encrypted data transmission to eliminate misoperation. OLED screen with anti-glare function for accurate weight and operating current display. Multi-LED indicators of operating status and limit status for easy troubleshooting.

- Hidden built-in radio omni-directional smart RF antenna to effectively eliminate wiring failure for better communication performance. Two-way wireless transmission control over 100m to feedback instant and clear status to the operator.

Specifications

| Model | CH610-7R5/2R2/R75 CH610-011/7R5/004 CH610-018/5R5/2R2 CH610-018/7R5/004 CH610-022/7R5/004 CH610-030/011/004 CH610-037/015/004 CH610-045/015/7R5 CH610-055/022/7R5 |

|---|---|

| Type | Lifting mechanism Trolley Crab |

| Drive Power | Three-phase 380V |

| Motor Power | Lifting mechanism: 7.5kW-55kW Trolley: 2.2kW-22kW Crab: 0.75kW-7.5kW |

| Rated Voltage | Three-phase 380V |

| Rated Current | 3A-110A |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| CH610 Integrated Crane AC Drive Catalog | Catalog | English | 2025-03-27 | 3.48MB |

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message