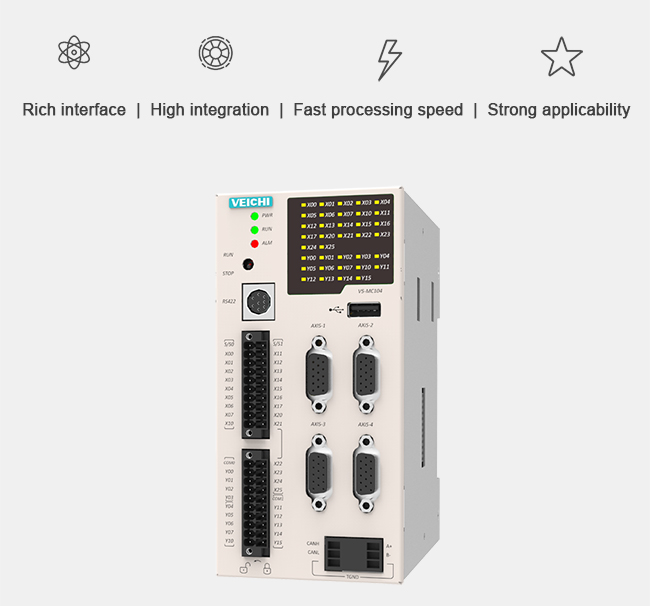

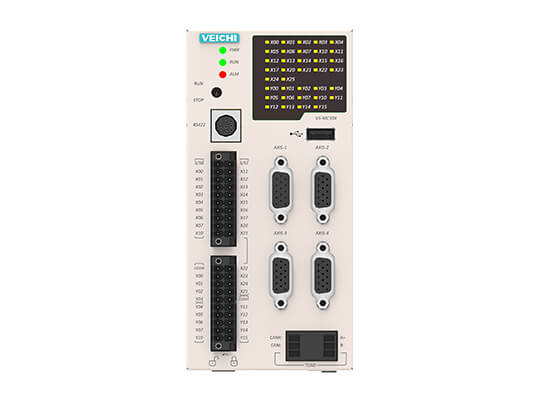

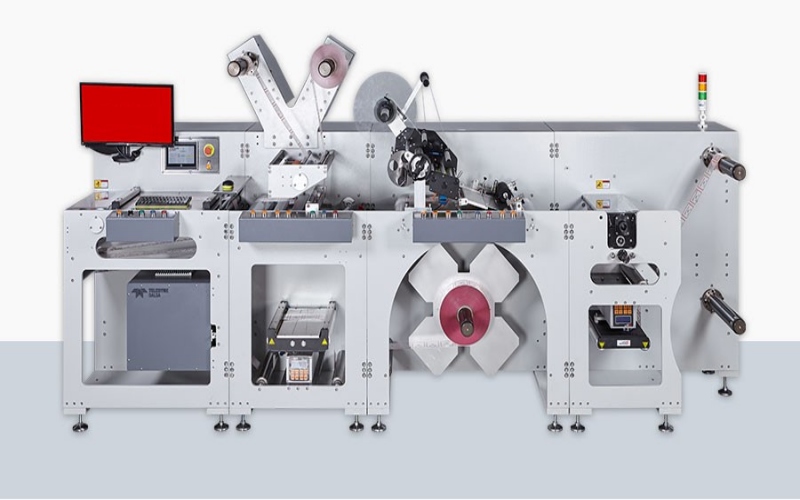

V5-MC104 Motion Controller

- Support multiple programming languages

- Support a variety of communication modes

- Support 16-axis synchronous motion; control cycle is within 1ms

- Adopt a multi-axis closed-loop high-speed pulse acquisition interface

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

V5 motion controller Overview

The V5-MC104 series motion programmable logic controller is a multi-axis motion controller developed based on a high-performance processor designed for various industrial automation environments.

1. Support 16-axis synchronous motion, control cycle 125s-1ms.

2. Powerful I/O management and functions meet the logic control requirements of the control system.

3. Modular thinking, convenient function module packaging.

4. Good inheritability, shorten the project development cycle.

5. Users can choose the programming method according to their own habits.

6. Integrate multiple function blocks, just call to apply.

7. Support multiple communication methods.

8. A variety of programming methods, easy to use.

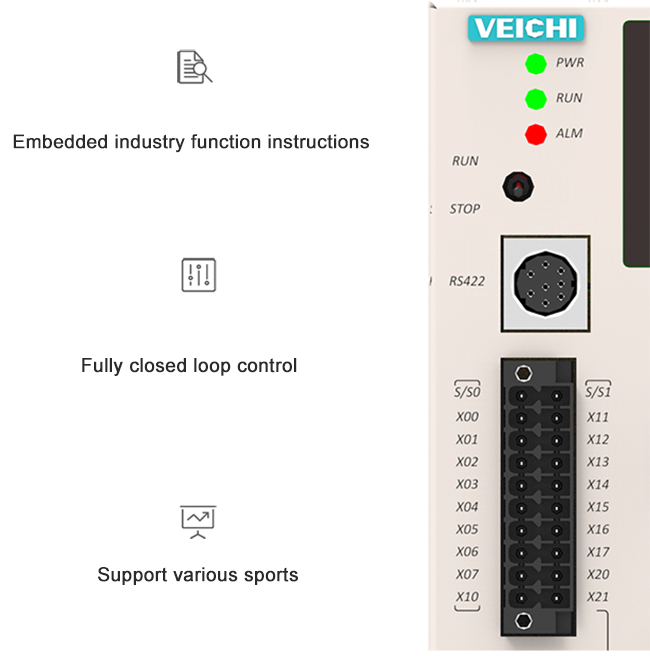

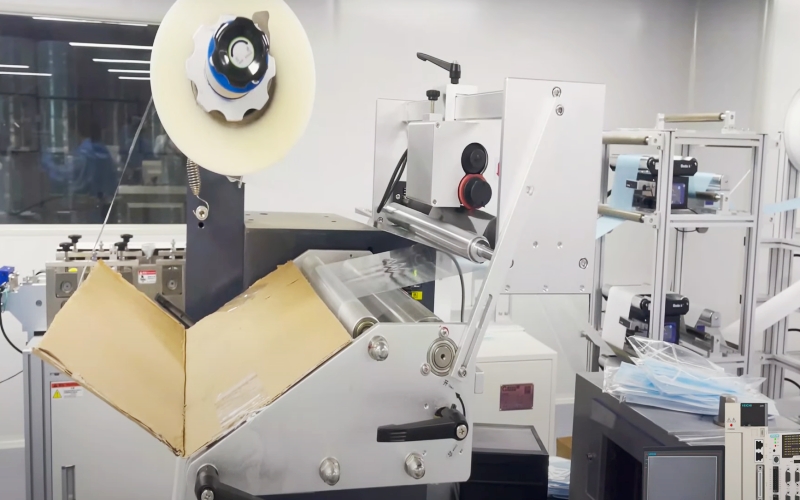

Wide range of applications

1. Support jog movement, linear interpolation, arc, 3D arc, electronic gear/cam, etc.

2. Built-in a large number of convenient industry function instructions, such as winding, tracking shear, flying shear, packaging, and other industry modules, make the application very simple.

3. Function blocks such as integrated synchronous follow-up, full-closed-loop control, and multi-axis cooperative motion control can be applied simply by calling.

Dual-core main chip, better performance

1. The main chip has dual-core processing and powerful logic operations.

2. The output frequency can be up to 3M.

3. The minimum control period can reach 125s.

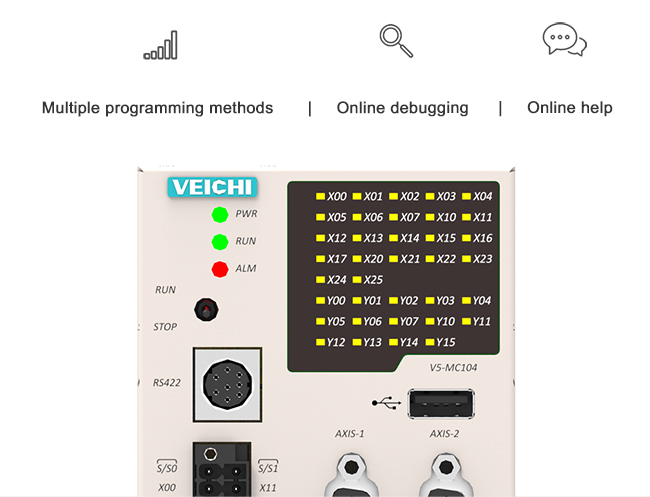

Support online debugging, more convenient operation

1. It supports four programming methods including ladder diagram, instruction list, MC instruction, and G code.

2. Support online debugging and online simulation debugging.

3. Users can quickly find help through the detailed online help function.

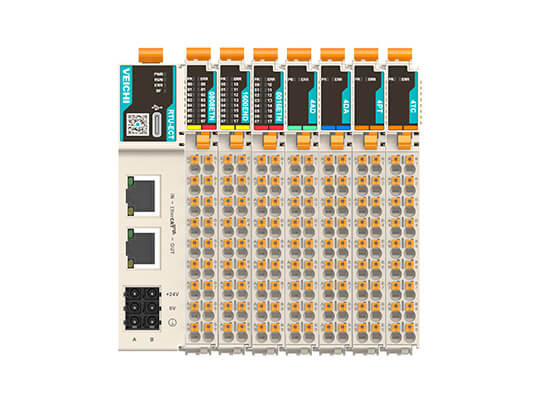

Support multiple interfaces, more comprehensive expansion

1. Support multiple communication methods such as RS422, RS485, RS232, CAN, EtherNet, etc.

2. Support USB HOST interface, file copy, and system upgrade.

3. 4-channel AD, 2-channel DA.

4. Expandable input and output interface.

Higher security, more reliable system

1. Support user program encryption, multiple encryption.

2. Support user program encryption, multiple encryptions.

3. Have higher seismic resistance and interference capabilities.

Structural design is more in line with industrial site installation requirements

In the structure, the traditional motion controller design method is abandoned, and the book design is adopted, which is more compact and beautiful. The DIN rail installation also saves a lot of space.

V5-MC104 Motion Controller Video

Industrial Applications for V5 Motion Controller

Applications:Woodworking machinery, textile machines, industrial robots, chase shears, flying shears and other occasions.

Specifications

| Software platform | Support ladder diagram, instruction table, sequence function diagram, G code Support remote network access and maintenance Multi-encryption function to ensure user intellectual property rights Support network variables for multi-robot coordination control |

|---|

| Program running mode | Adopt scan mode that can be set to fixed cycle scan, internal event trigger and external event trigger |

|---|---|

| Debugging function | Support online debugging and online simulation debugging |

| Online help function | Users can quickly find help through detailed online help function |

| Function module development | Users can easily carry out a variety of modular encapsulation for shift and reuse of the program |

| Software encryption function | Main program encryption, subroutine encryption, upload and download function encryption, user self-encapsulation function module encryption |

| Remote diagnostic function | Users can remotely log on to the target machine via Ethernet and perform online modification, debugging and operation of programs to realize diagnosis and maintenance of the machine |

| Simulation function | Users can perform simulation running and debugging |

| Control mode | Motion control, logic control |

| Image processing function | Connected to the CCD to ensure processing accuracy through visual positioning |

| Compensation function | Own a backlash compensation function |

| CPU clock speed | 168M |

|---|---|

| Memory | 64M |

| Display interface | RS422, network port |

| USB | 1 × USB2.0 |

| COM port | 1×RS-232, 2×RS-48, 1×RS-422 |

| Ethernet | 1×10M/100M adaptive |

| Pulse signal | Differential pulse, 4MHz |

| Encoder signal | 4MHz |

| AD interface | 12bit × 2 |

| Digital IO | 22 input, 14 output |

| Cycle | Control cycle: 1ms |

| Field bus | EtherCAT/CAN/MODBUS |

| Extended functions | Extensible I/O modules, axis modules |

| Power requirements | +24V±10%, Icc=3A |

| Motion control function | Point motion JOG Electronic gear Electronic cam 2, 3 linear interpolation Three-plane circular interpolation Position comparison output Backlash compensation |

| Operating temperature | 0~55 ℃ |

| Operating humidity | 5%~90% without condensation |

| Controller dimension | 155mm×76mm×110mm |

| Remote IO module | V5-MC104 has a powerful motion control function that can offer a wide range of digital input and output modules, analog input and output modules, thermocouple input module, relay output module and other IO modules. It can be extended to 200 IO points to meet all kinds of industrial applications of logic control and a variety of signal input and output functional requirements. |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| CE (EMC) of V5 Series PLC | Certificate | English | 2024-07-24 | 1.34MB | |

| V5 Series PLC Instructions Simple Manual V1.0 | Manual | English | 2021-01-07 | 2.73MB | |

| V5 Series PLC Instructions and Programming Manual V1.0 | Manual | English | 2019-12-23 | 4.72MB | |

| V5 Series PLC SETUP V1.0.55 | Software | English | ZIP | 2020-08-11 | 36.4MB |

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message