Air/ Maglev Compressor Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Air/ Maglev Compressor Solution

The air/maglev compressor offer advantages over traditional air compressors, including higher speeds, longer equipment lifespan, and small size, gaining a growing market share.

VEICHI's air/maglev compressor system, featuring our own control and drive products, employs precise pressure and flow algorithms for accurate and stable equipment operation.

Features and Benefits

VEICHI's air/maglev compressor system, utilized across sectors such as water treatment, papermaking, pneumatic conveying, coal chemical, electroplating, and power generation, incorporates high-performance automation products from VEICHI. Core components including VC3 controllers, AC drives, and HMIs ensure system's high stability and compatibility. Equipped with comprehensive safety features like surge, flow, pressure, power, and current monitoring, the system supports various operational modes: RPM, pressure, velocity, power, and current, catering to diverse industry needs. Its open parameters give customers the flexibility to customize equipment settings and finely adjust sensor parameters across different manufacturers' machines. VEICHI's air/maglev compressor system distinguishes itself with robust safety, versatility, and open parameter settings, offering a dependable solution for a breadth of industrial applications.

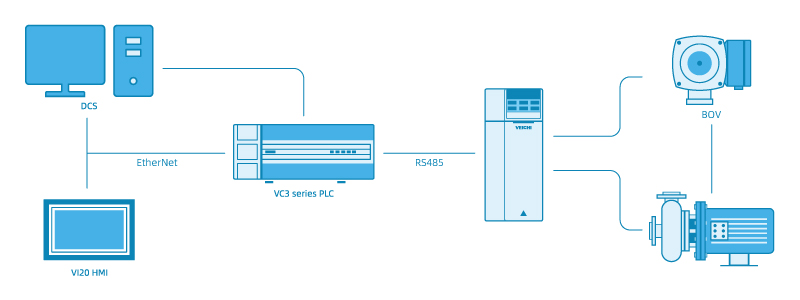

System Topology

The VC3 controller, supplemented with analog I/O and RTD temperature modules, plus a 485 expansion, is the core of our control system, offering strong performance and value. Integrated sensors ensure equipment safety, while its algorithms maintain flow and pressure control within a 5% accuracy.

System Feature

High Stability and Compatibility

The system adopts VEICHI's high-performance automation products as the core components, ensuring superior stability and compatibility.

High Security

The system features comprehensive safety measures, including surge detection, flow, pressure, displacement, speed, power, and current curve monitoring, as well as extensive temperature checks with exceedance alarms. In addition to these, maglev compressors also offer bearing safety, communication checks, and end-bearing temperature detections, ensuring all-around protection for the equipment.

Comprehensive Functions

The system meets all industry requirements with five operating modes—RPM, pressure, velocity, power, and current—and various control options, including local HMI start, local terminal start with auto-upload/download, remote IP and RS-485 control, and remote terminal start.

Adjustable Parameters

Customizable parameters for fine-tuning of sensors ensure compatibility with machinery from all manufacturers.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message