New Energy Power System Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

New Energy Power System Solution

Ports and terminals are critical hubs for global trade, handling vast amounts of cargo daily. However, traditional crane operations often rely on energy-intensive systems that contribute to high operational costs and significant carbon footprints. To address these challenges, GT Electric has leveraged cutting-edge technology to create a solution that not only enhances operational efficiency but also supports environmental sustainability.

In the pursuit of sustainable and efficient port operations, GT Electric, a subsidiary of VEICHI, has developed innovative solutions that integrate high-performance converters with advanced battery technology. This combination is specifically designed to deliver more efficient, energy-saving, and environmentally friendly control solutions for a wide range of port applications.

Features and Benefits

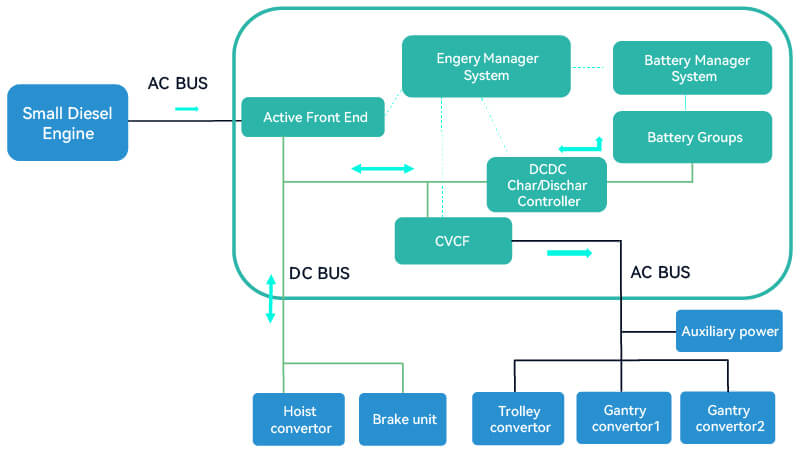

1. Solution for Small Diesel Engine+High Rate Battery System

Committed to achieving the goal of "energy conservation and emission reduction" for port equipment.

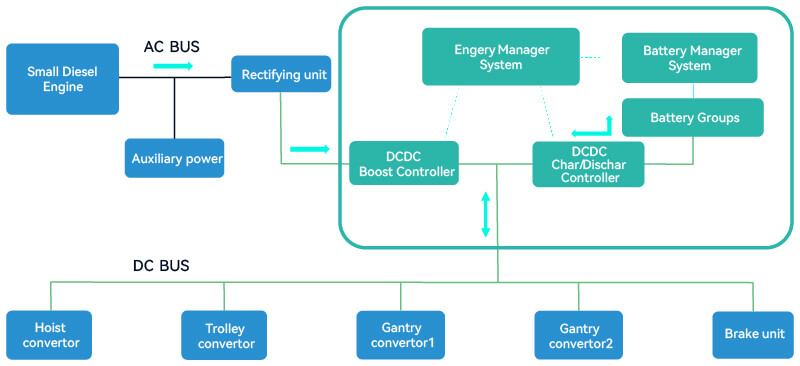

Hybrid solution 1

• High-rate batteries and a small diesel engine work together to provide hybrid power, enabling all RTG mechanisms to operate at full power.

• When battery power is low, the diesel engine automatically charges the batteries and remains running.

• The auxiliary power for the entire machine is supplied by the diesel engine.

Operating Principle:

①During lifting, both the diesel engine and the batteries work together to provide power.

②During lowering, energy is recovered and stored in the batteries via the DC/DC charge-discharge device.

③The auxiliary power for the entire machine is supplied by the diesel engine, which remains running.

④When the battery level is low, the diesel engine charges the batteries through the rectifier and booster device, and then via the DC/DC converter.

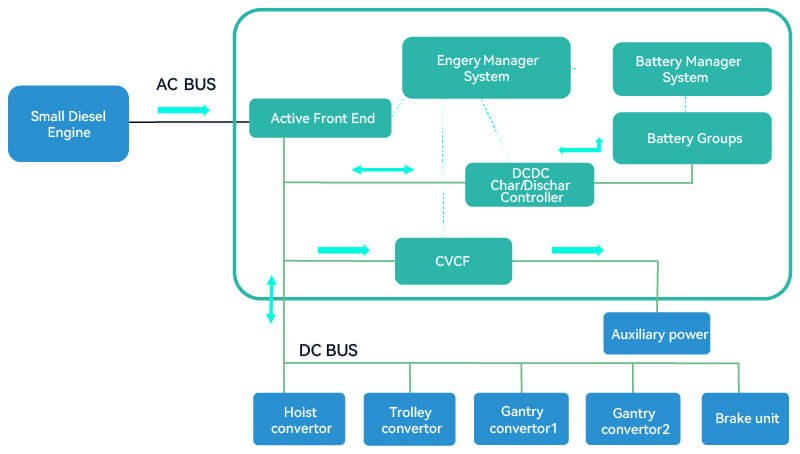

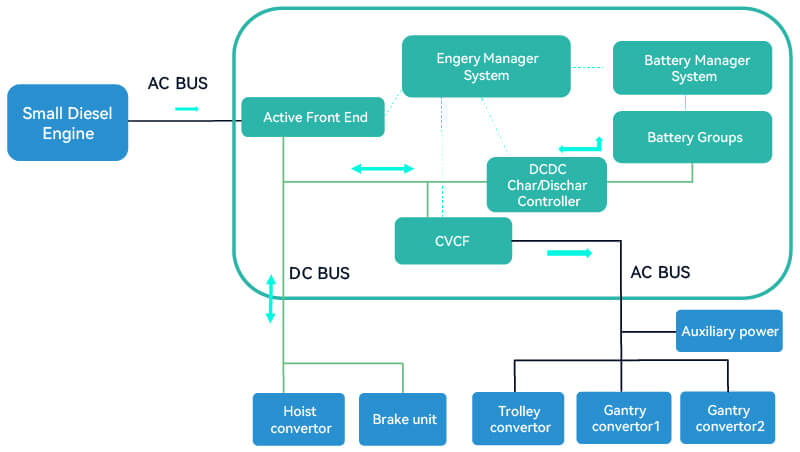

Hybrid solution 2

• The batteries can supply power independently, enabling all RTG mechanisms to operate at full power.

• When the battery level is low, the diesel engine starts to charge them and shuts down once the set level is reached.

• The auxiliary power for the entire machine is provided by the batteries.

Operating Principle:

①The batteries can independently power the entire machine. During lifting, the batteries discharge through the DC/DC converter to provide power, and during lowering, energy is recovered and stored in the batteries via the DC/DC converter.

②The auxiliary power for the entire machine is supplied by the CVCF (Constant Voltage Constant Frequency) unit.

③When the battery level is low, the diesel engine starts and charges the batteries through the rectifier and booster device, then via the DC/DC converter, and shuts down once the set charge level is reached.

Characteristics

• Hybrid Power Supply: Combines battery and diesel power to energize cranes.

• 70% Power Reduction: Replaces large diesel engine with smaller one, cutting emissions and energy use.

• Energy Recovery: Captures crane potential energy during descent and stores it in batteries.

• High-Power Battery: Equipped with high-rate battery pack delivering instant peak power.

• Optional CVCF Inverter: Auxiliary power from batteries allows diesel engine to work intermittently, saving more energy.

Advantages

• Diesel engine cost savings > 70%.

• Diesel fuel savings > 60%.

• Diesel engine maintenance cost savings > 70%.

• Renewable energy charging for battery packs.

• Maintains the operational flexibility advantages of RTG.

• Utilizes leading battery brands for safety and reliability.

• Independently developed AFE rectification and boosting, DC/DC charging/discharging, and CVCF inverter technologies ensure system stability and reliability.

• Independently developed IoT cloud platform enabling remote monitoring, GPS tracking, and other functions.

• Brake resistors reduce thermal pollution.

• Carbon emissions reduction > 60%.

RTGC can operate in any container yard area, maintaining equipment flexibility.

Small Diesel Engine + High-Rate Battery System Products

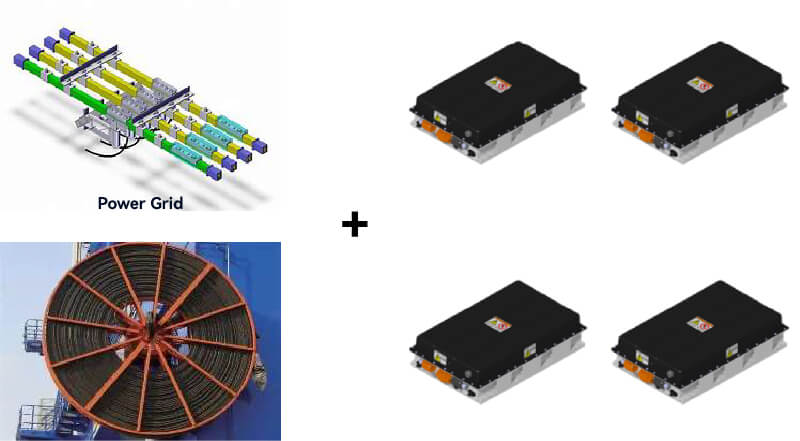

2. Solution for Power Grid+Small Capacity Battery System

Committed to achieving the goal of "zero emissions" for port equipment.

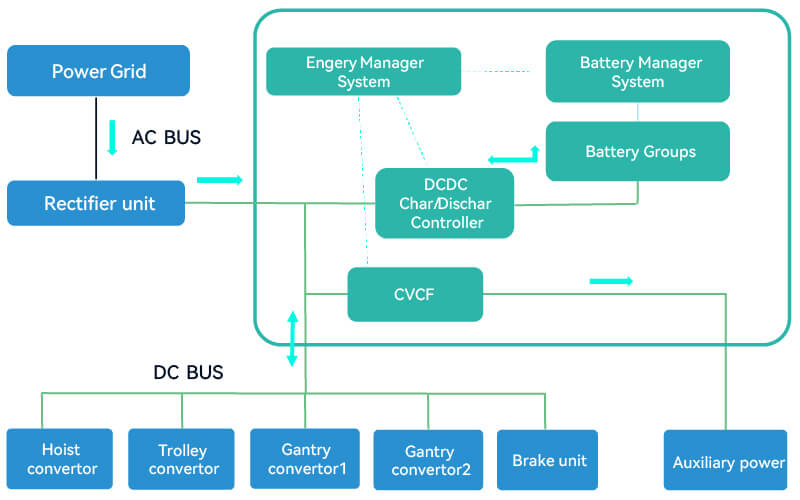

Solution 1(Power Grid+Blockchange)

• Battery-Powered Replacement for Diesel Engine.

• Battery-powered operationprovides sufficient energy for the gantry crane to travel more than2 km.

• When the battery level is low, the crane enters themains power areafor recharging.

Operating Principle:

①Normal Operation in Contact Line Area:The mains power supplies the entire machine, and the battery remains inactive.

②Transfer Operations:When the RTG needs to relocate, the battery system activates, boosting power through a DC/DC converter to supply the traveling mechanism.

③Auxiliary Power:All auxiliary systems receive power through a CVCF (Constant Voltage Constant Frequency) inverter.

④Battery Charging:When battery level is low, mains power in the contact line area charges the battery through rectification and DC/DC conversion.

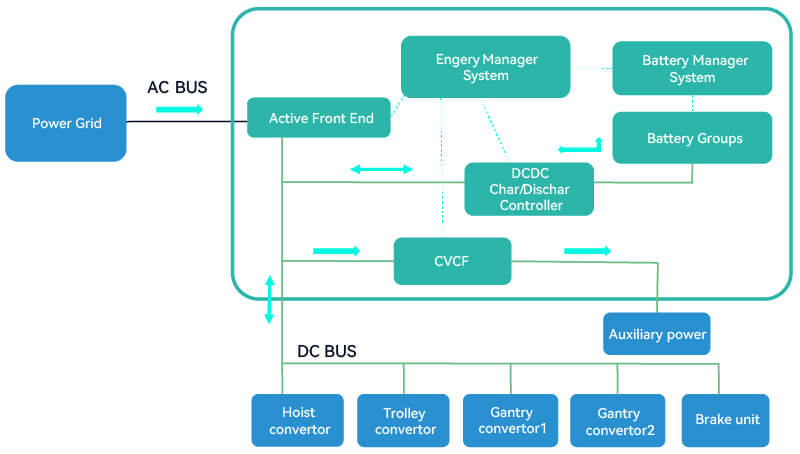

Solution 2(Power Grid+Peakpower shaving+Block change)

• Power Grid+Peakpower shaving+Block change.

• Battery-Powered Replacement for Diesel Engine.

• Battery-powered operationprovides sufficient energy for the gantry crane to travel more than2 km.

• When the battery level is low, the crane enters themains power areafor recharging.

• Mains power peak shaving function limits grid power consumption, reduces electricity costs, and eliminates the need for mains capacity expansion.

Operating Principle:

①Lifting Operation in Contact Line Area: The AFE limits grid power consumption and suppresses harmonics while the battery provides power compensation. During lowering, energy is recovered to the battery.

②Transfer Operations: When the RTG needs to relocate, the battery system activates, boosting power through a DC/DC converter to supply the traveling mechanism.

③Auxiliary Power: All auxiliary systems receive power through a CVCF (Constant Voltage Constant Frequency) inverter.

④Battery Charging: When battery level is low, mains power in the contact line area charges the battery through rectification and DC/DC conversion.

Characteristics

• The battery replaces the original diesel engine, resulting in zero pollution.

• Mains power peak shaving functionality reduces electricity costs and eliminates the need for mains capacity expansion.

• During peak shaving scenarios, the battery provides power compensation, and energy regenerated by the crane is stored in the battery.

• The battery supplies power to the traveling mechanism for relocation.

• When the battery level is low, it is recharged from the mains power supply.

Advantages

• The terminal achieves "zero emissions".

• Limits terminal mains grid power consumption, reduces electricity costs, and eliminates the need for mains capacity expansion.

• Smooth grid peak shaving functionality.

• Grid harmonic suppression < 5%.

• RTG grid demand limit < 150 kW.

• Travel distance > 2 km on a single charge.

• Adopts leading battery brand for safety and reliability.

• Self-developed AFE rectifier/booster, DC/DC charging/discharging, and CVCF inverter technologies ensure stable and reliable system operation.

• Self-developed IoT cloud platform enables remote monitoring, GPS positioning, and other functions.

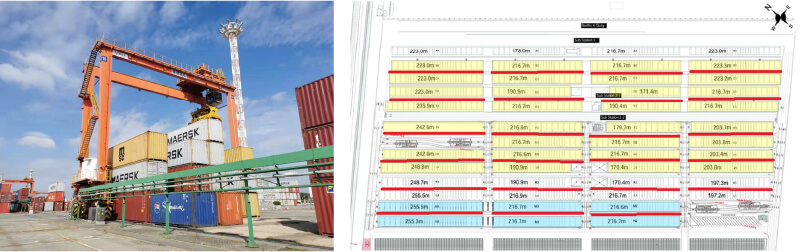

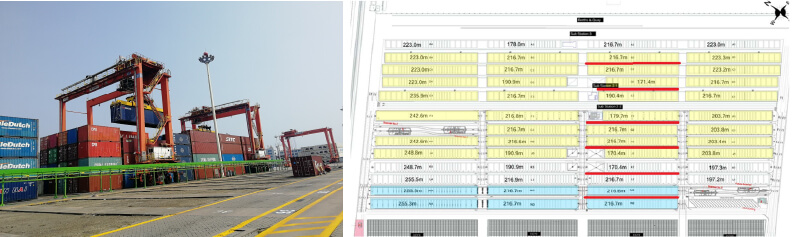

➢The red area is the terminal's mains-powered contact line zone.

➢The peak-shaving system limits the mains grid power consumption to less than 150 kW.

Power Grid+Small Capacity Battery System Products

3. Solution for Power Grid+Large Capacity Battery System

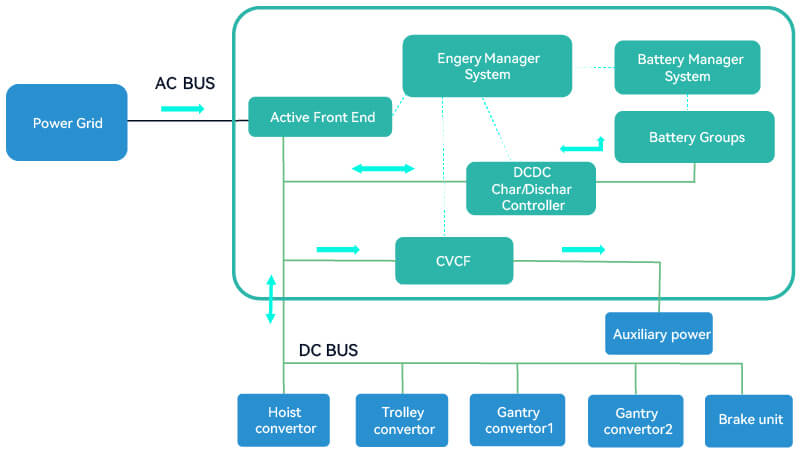

Operating Principle:

① A high-capacity battery is used to provide all the power for the RTGC, enabling long-duration operations.

② Energy regenerated by the crane is charged into the battery through the DC/DC converter.

③ Auxiliary power for the entire machine is supplied through a constant voltage, constant frequency (CVCF) inverter.

④ When the battery level is low, it is recharged from the mains power supply in the contact line area, allowing the RTGC to continue operating while charging.

⑤ Once the battery is charged to the set level, the RTGC can operate in any container yard area.

Characteristics

• A high-capacity battery (greater than 400 kWh) provides power for the entire machine.

• All renewable energy generated by the crane is absorbed into the battery.

• The RTGC's auxiliary power is supplied by the battery through a CVCF (Constant Voltage Constant Frequency) inverter.

• The high-capacity battery RTG can operate in any yard area for extended periods.

• When the battery level is low, it is recharged from the mains power supply.

Advantages

• The terminal achieves "zero emissions".

• RTGC battery continuous operation time > 8 hours.

• Significantly reduces initial investment costs for terminal mains power.

• Eliminates the need for RTGC braking units and braking resistors.

• Limits terminal mains grid power consumption, saves electricity costs, and eliminates the need for mains capacity expansion.

• Adopts leading battery brand for safety and reliability.

• Self-developed AFE rectifier/booster, DC/DC charging/discharging, and CVCF inverter technologies ensure stable and reliable system operation.

• Self-developed IoT cloud platform enables remote monitoring, GPS positioning, and other functions.

➢ The red area is the RTGC mains charging zone.

➢ The high-capacity battery allows operation in any yard area.

Power Grid+Large Capacity Battery System Products

4. Other Solutions for New Energy Power system

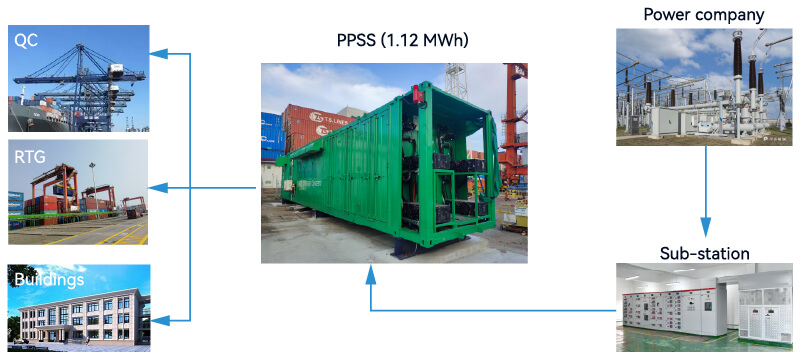

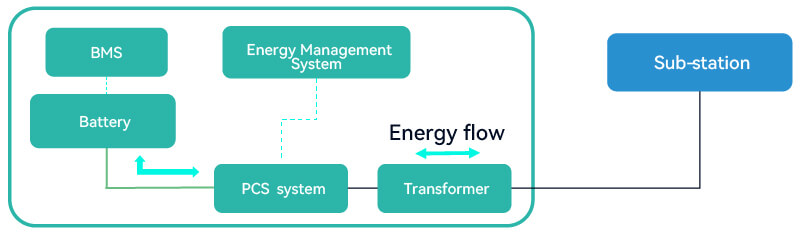

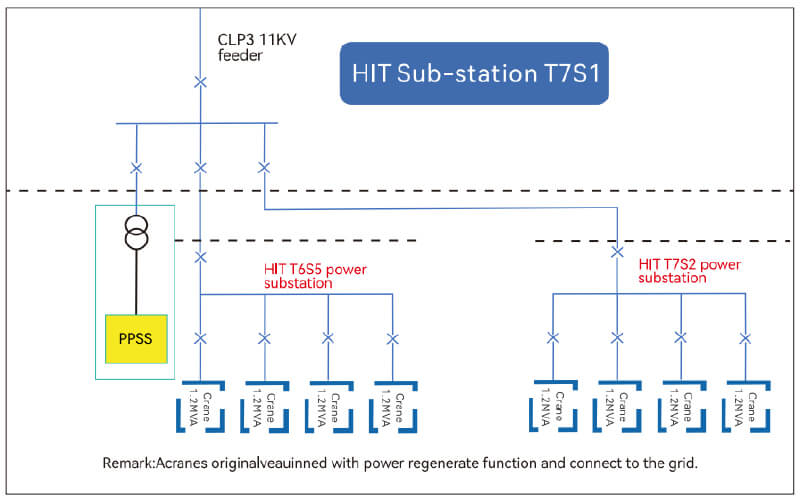

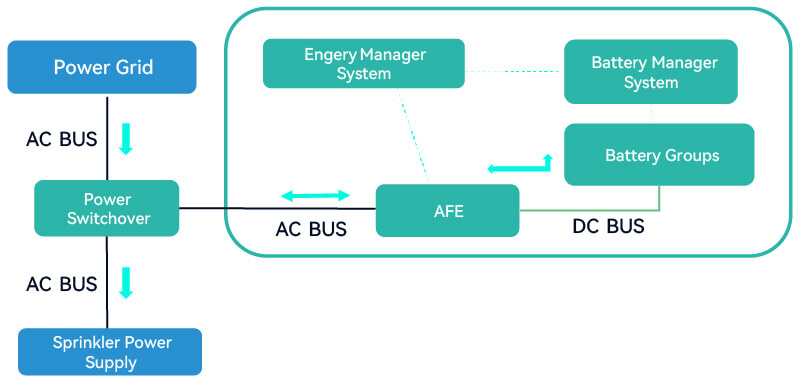

(1)Peak Power Shaving System

PPSS provides power to the lifting machines to reduce the peak current demand.

Working principle:

➢Battery discharge: battery energy output to the power transformer through the PCS installation.

➢Battery charging: city mains (11KV) charge the battery through the PCS installation during the non-peak period.

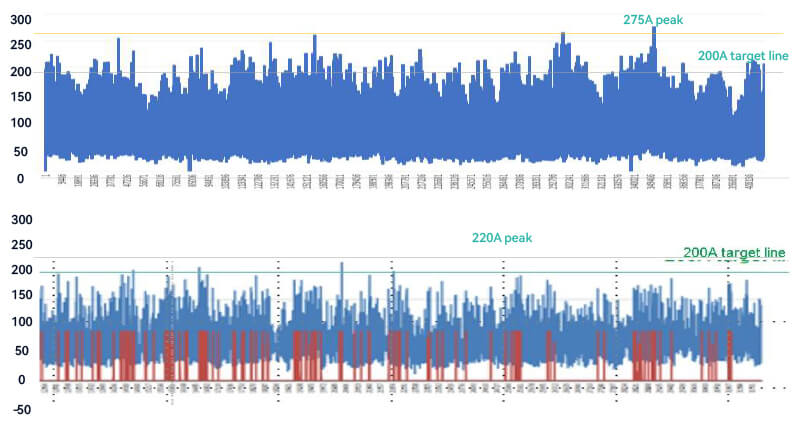

Peak current (w/o PPSS):275A

Peak current demand reduced

Peak current (with PPSS):220A

Blue:Sub-station main current 220A peak Red:PPSS output current, negative means battery under charging mode

System highlights

◆ To meet current demand for terminals, large compensation in short period of time.

◆ With high quality and safe battery packs.

◆ High rating battery system for high power output.

◆ Self control system, automatic charging, fast response to the high power output demand.

◆ Scheduled charging program to realize the ‘Off-peak’ charging function.

◆ Separated system equipped with fire fighting system.

◆ Remote monitoring system.

◆ Reduce the investment cost for expending the power supply network.

Test result

With 1.12 MWh battery storage system, the PPSS system is able to compensate 2MW/30s peak current demand.

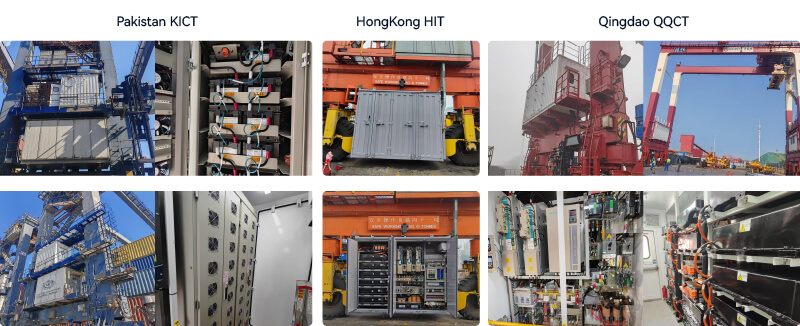

HIT project

(2)Single-Drive RTG Battery Hybrid System

Operating Principle:

① The battery can independently power the entire machine. When the lifting mechanism ascends, the battery discharges through the DC/DC converter to provide power; during descent, energy is recharged into the battery through the DC/DC converter.

② The travel, traverse, and auxiliary systems receive power through a CVCF (Constant Voltage Constant Frequency) inverter.

③ When the battery level is low, the diesel engine/mains power is activated to charge the battery through the AFE rectifier/booster and DC/DC converter.

(3)Single-Drive RTG Battery System for Block Change

Operating Principle:

① When the RTGC needs to relocate, the battery system is activated, and the battery outputs AC power through the PCS device to provide power to the traveling mechanism.

② During relocation, the auxiliary power for the entire machine is supplied by the PCS.

③ When operating in the mains power area, the machine's power supply is switched to be provided by the mains.

④ When the battery level is low, it is recharged through the PCS device in the mains power area.

(4)Battery Power System for Sprinkler Trucks

Operating Principle:

• When the sprinkler needs to operate, the battery system is activated, and the battery outputs AC power through the AFE device to provide power to the entire vehicle.

• When the battery level is low, the sprinkler drives to the mains power area to recharge the battery through the AFE device.

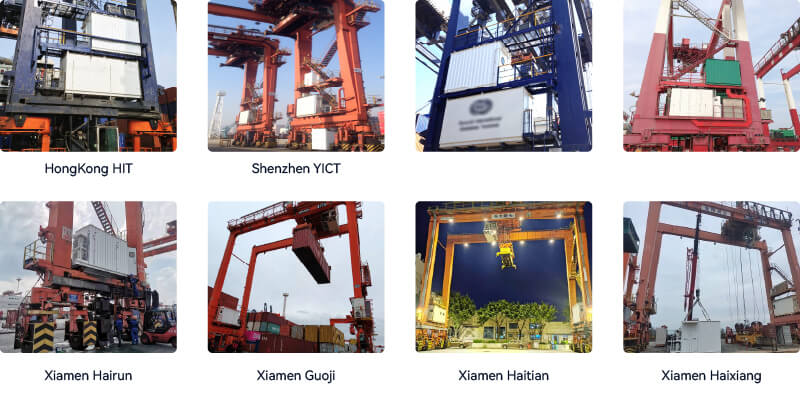

Application Cases

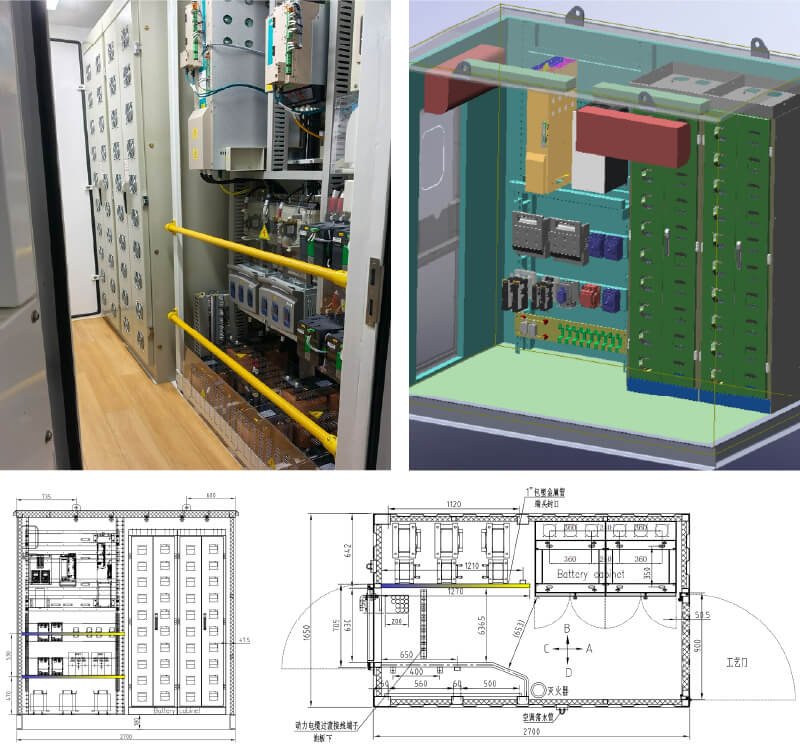

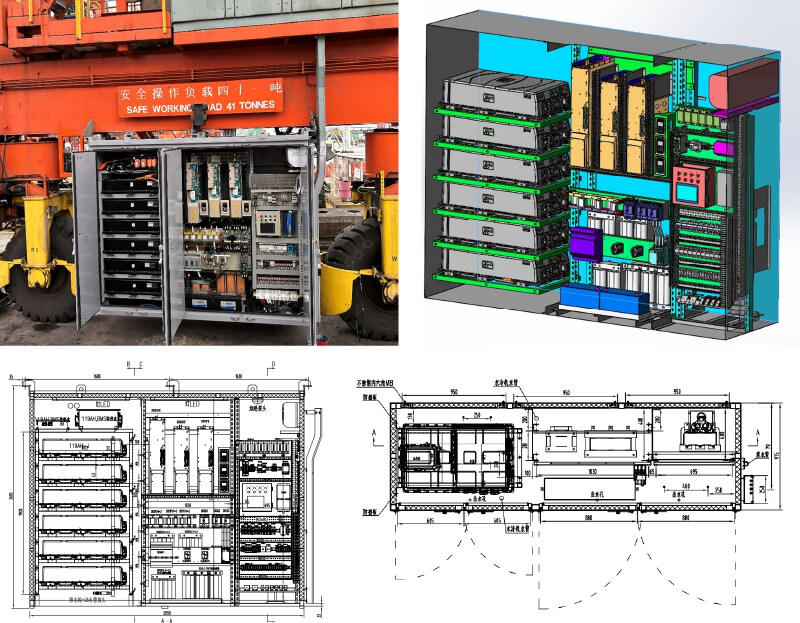

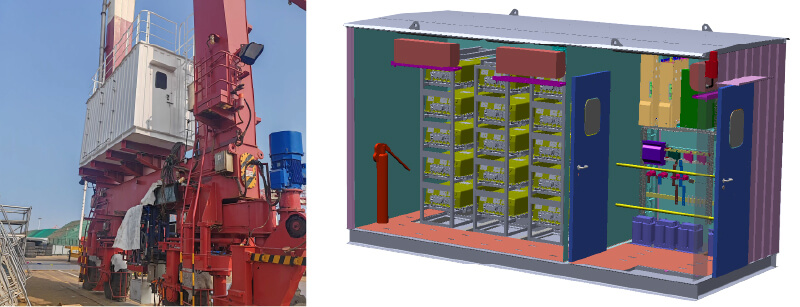

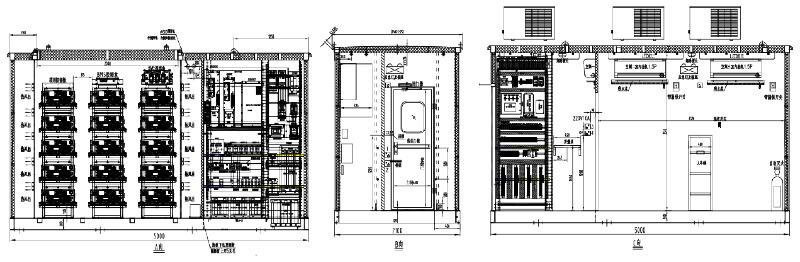

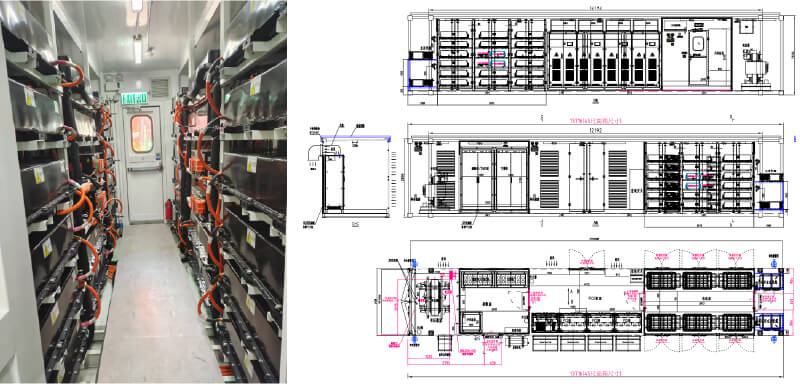

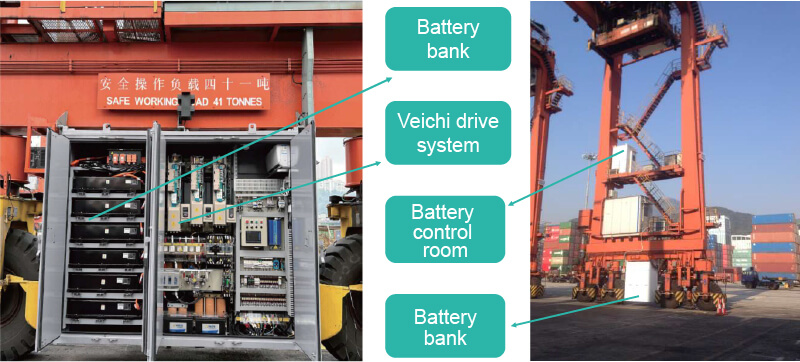

Typical installation

Single electrical room for battery and control systems & Separated electrical rooms for battery and control systems

Applications of RTG Battery Systems

Nanjing Longtan

Indonesia JICT

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message