- Home > Product > Motion Control > AC Servo System > V9E Series General Servo Motor

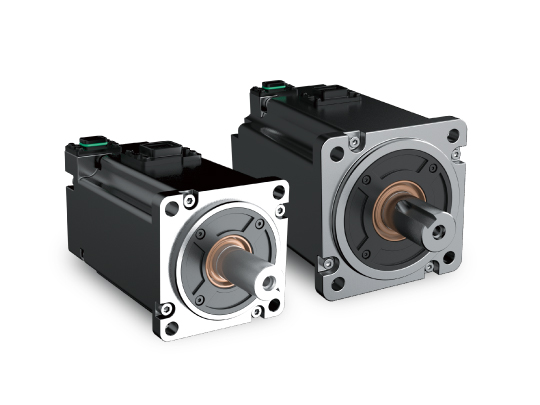

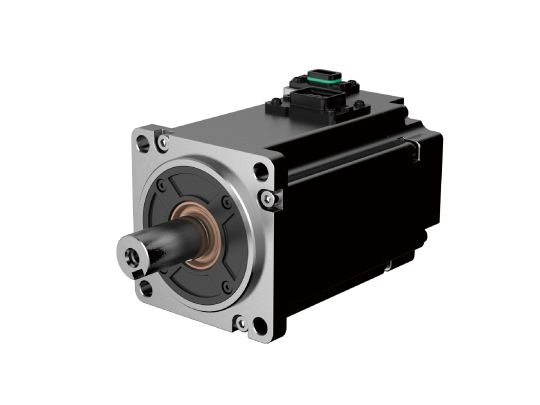

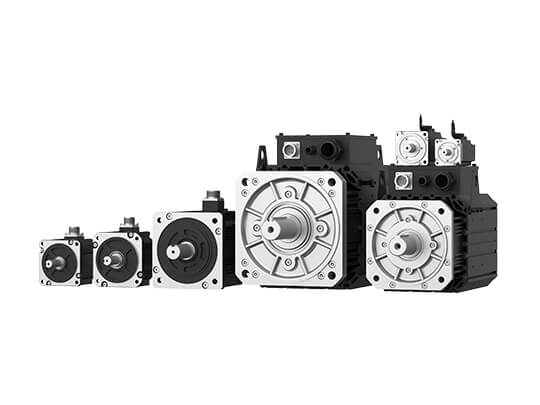

V9E Series General Servo Motor

- More models, low-inertia 60/80/100/130 mm flange added.

- Wider speeds, enhanced motor speed for higher working efficiency.

- Smaller sizes, length shorted by 3-5%.

- Superior position accuracy.

- Better performance, reduced 2-4℃.

- Low energy, meets Class 1 requirements of GB30253.

- Higher protection: IP67.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

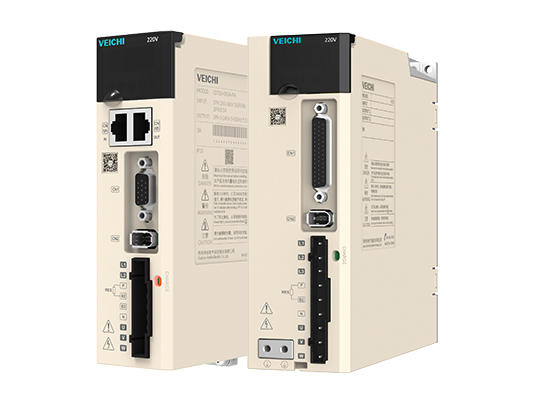

- Related Products

- Additional Information

V9E Series Servo Motor Overview

VEICHI V9E series general servo motor is one of VEICHI new generation general servo motor series, widely used in semiconductors, industrial robots, auto production lines, precise machine tools.

Product Features

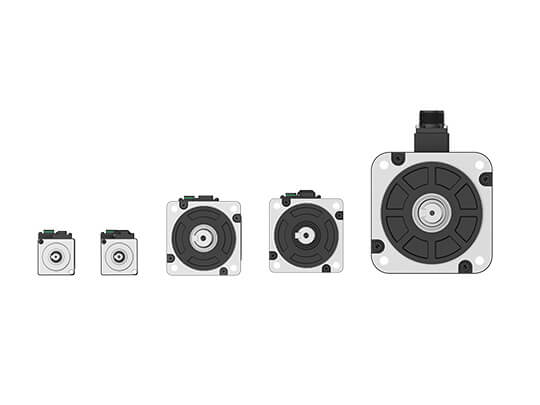

1. More models

Low-inertia 60/80mm flange added: Applicable to quick position control occasions like semiconductor, 3C, and lithium industry.

Low-inertia 100mm flange added: Applicable to limited installation space like multi-joint robots and spring machines.

Low-inertia 130mm flange added: Applicable to large load at high speeds or occasions with frequent start/stop operations .

2. Wider speeds

Enhanced motor speed for higher working efficiency.

V9E 40/60/80mm flange: Max speed raised from 6000rpm to 7000rpm.

V9E 130mm flange: Max speed raised from 3000rpm to 5000rpm.

V9E 180mm flange: Max speed raised from 3000rpm to 4000 rpm.

3. Smaller sizes

Length shorted by 3-5%.

4. Superior position accuracy

24bit or above encoders optional for stable operation and orientation.

5. Better performance

New magnetic circuits with smaller cogging torque and temperature rise, smoother shaft rotation and more accurate position control at low speeds compared to typical model from V7E series under similar conditions.

6. Low energy

V9E series meets Class 1 requirements of GB30253.

7. Higher protection

IP67 (except for shaft extension) for the whole body against water, spray, dust and iron filings in various environments.

Battery-free Multi-turn Encoder

Maintenance-free for green use

Say goodbye to depleted batteries and unscheduled maintenance.

Procedure-free for batter export

Say goodbye to the battery control due to flammability and explosiveness.

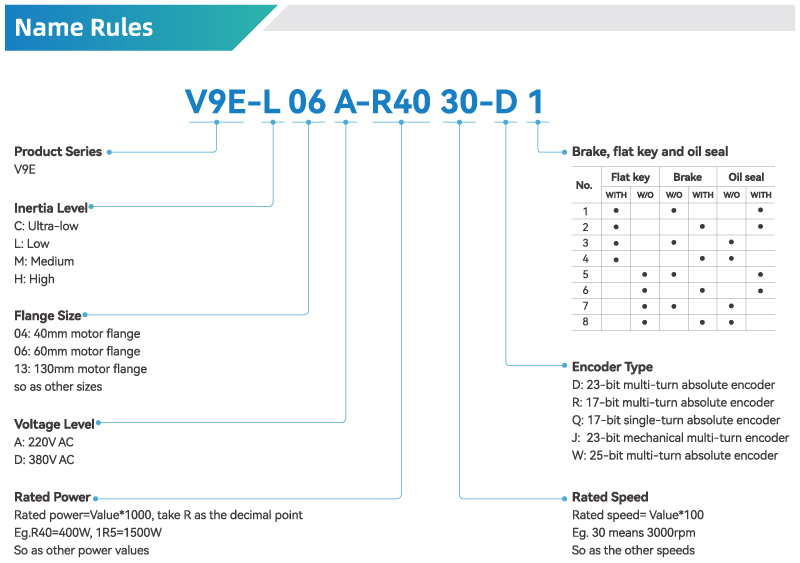

Name Rules

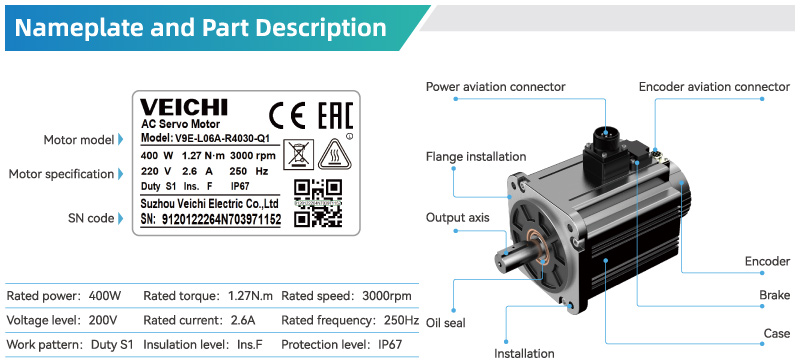

Nameplate and Part Description

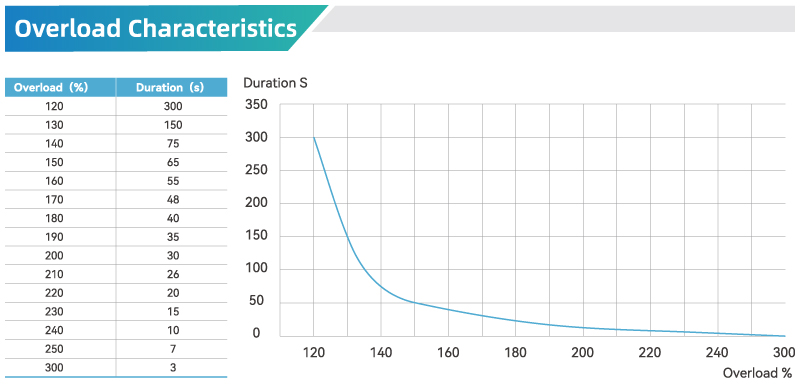

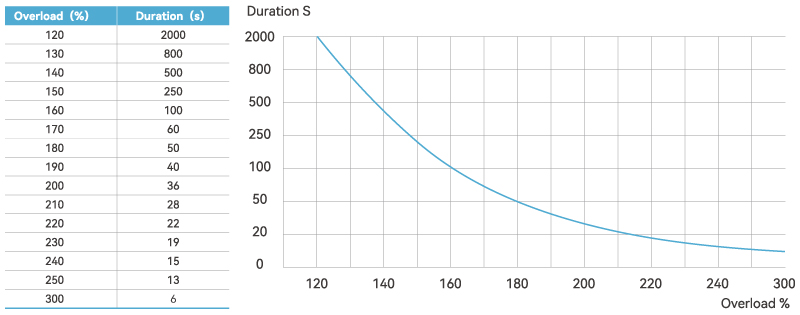

Overload Characteristics

Note:

1. The overload characteristic diagram above applies to the motors with 100, 110, 130, 180mm flanges (850W~7500W, inertia-irrelevant);

2. V9E series motors with VEICHI servo drives are designed with overload protection and overheat protection in accordance to the requirements of CE, UL and other certificates;

3. Servo alarm or motor failure may occur if overload operation time is exceeded. Make a comprehensive assessment on the operating load and working system before selecting the model, so as to avoid wrong selection of motors causing this problem.

4. Please set the motor overload protection gain according to its overload capacity in order to effectively protect the motors with different loads. The protection gain is generally kept to the default, but it can be changed according to the actual heat generation from the motor when the environment temperature is high or the acceleration/deceleration is frequent during the short cycle.

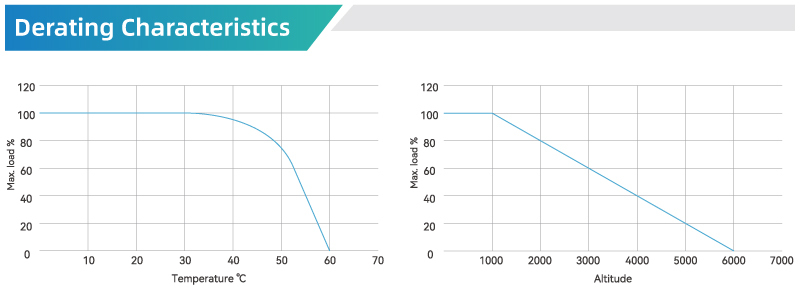

Derating Characteristics

Note1:

The ratings of the servomotor are the continuous permissible values for an operating ambient temperature of 40°C.

If the operating ambient temperature exceeds 40°C (max. 60°C), please refer to the derating curve shown in the above chart.

Note2:

The ratings of the servomotor are the continuous permissible values for an operating altitude of 1000m.

If the operating altitude exceeds 1000m (max. 2000m), the heat dissipation effect of air will be reduced, so please refer to the derating curve shown in the above chart.

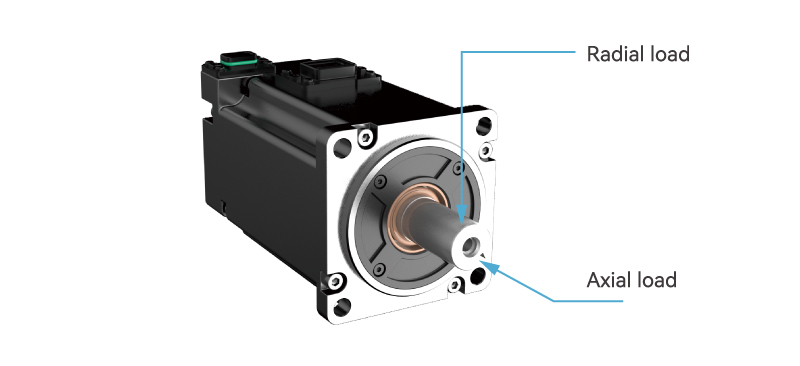

Load Inertia and Radial/Axial Loads

Load inertia:

This value is an approximate standard and may vary with the drive conditions of the servomotor, but the larger the load inertia is, the poorer the responsiveness is, and it may cause motion instability if it is too large.

If the servo drive is used beyond the allowable load moment of inertia, an overvoltage alarm occurs during deceleration. Besides, an overload alarm occurs when the servo drive has a built-in braking resistor.

Take any of the following measures when such an alarm occurs:

- Decrease the torque limit value.

- Decrease the deceleration curvature.

- Decrease the maximum speed.

If the alarm is not canceled after taking the above measures, an external braking resistor is required.

Radial/axial load:

This means the force that can be withstood on the motor axis during installation and operation, divided into radial and axial two components. The values given in this document are the maximum allowable values, i.e., noise, jamming, temperature rise abnormality, or extra wear and tear may happen once the values are exceeded, leading to shortened motor life or even damages. See the subsequent motor parameter table for details.

Model Selection

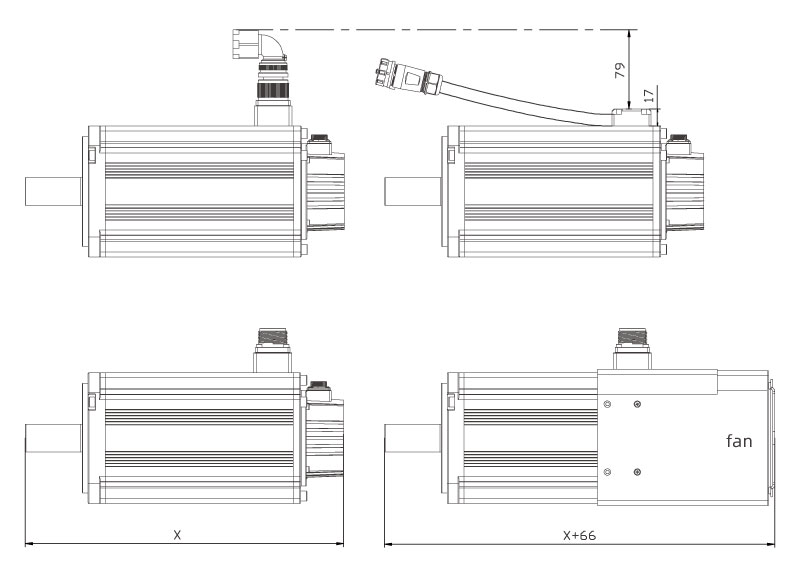

Optional flat aviation connector:

Application scenario:

Compact device size/compact motor mounting space.

Advantage:

Lower the overall height of aerial insertion to 79mm to effectively reduce mounting interference.

Optional cooling fan:

Application scenario:

High ambient temperature & airtight, poor cooling conditions.

Advantage:

Wide range of ambient temperatures to effectively protect the motor from overheating, resulting in use/lifetime damages.

Note: If the above options are required, please contact our sales staff or motor product engineers for any inquiries or orders.

Encoder:

- Excellent vibration resistance: magnetic coding.

- Excellent interference resistance: optical coding.

- Power-down position storage: multi-turn.

T-n curve:

- Continuous working zone: This means the states in which the motor can be operated safely and continuously. The actual torque must be within this zone.

- Short-term working zone: This means the states in which the motor can run for a short time when the actual torque is greater than the rated torque.

Brake:

- Purpose: To keep the rotor position of the motor from rotating after power loss, but it’s invalid during forced braking;

- Power: It is prohibited to share the power supply with other appliances to prevent the power supply voltage/current from decreasing and causing the brake mis-operation when other appliances are working.

Fan:

Optional:

① For enclosed environments where the ambient temperature is high and there is no air circulation.

② For occasions where the motor temperature rise will affect the precision of the equipment greatly.

AC 220V fan (used with air duct) is selected by default. And for other voltage levels, please ask VEICHI for special requirements.

Oil seal:

- Purpose: Protect shaft extension.

- Note: Derate 10% to use if there is a oil seal on the motor (Oil seal can be selected according to the installation environment).

Flat key:

- Purpose: Transmit the torque from the motor shaft to the actuator.

- Note: The flat key should be dismantled with the screws. Please do not hammer on the shaft.

V9E Series General Servo Motor Video

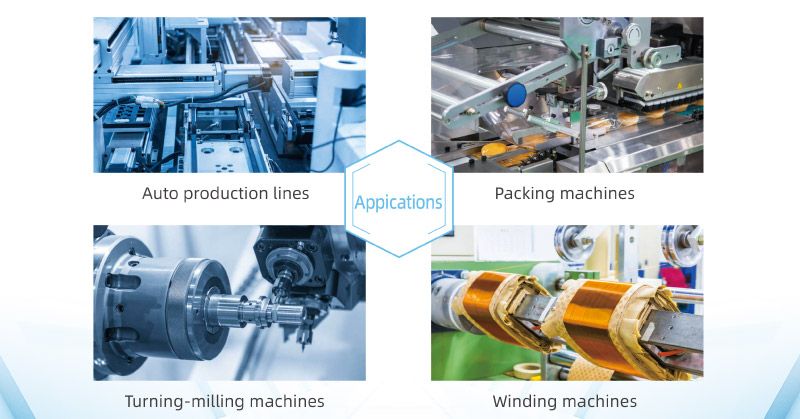

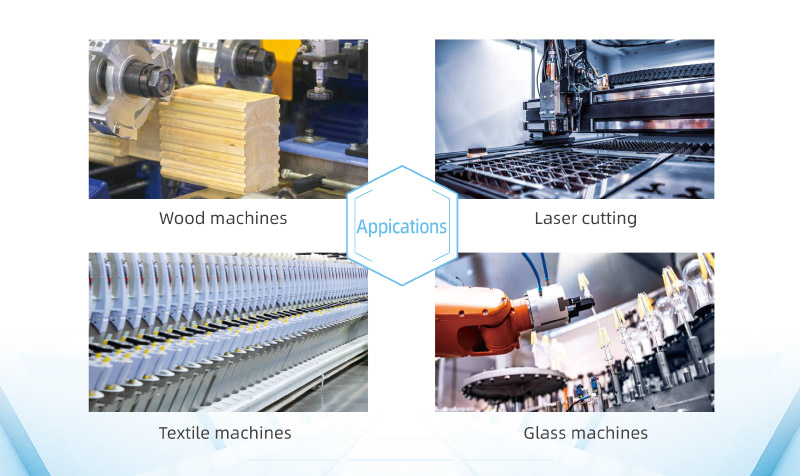

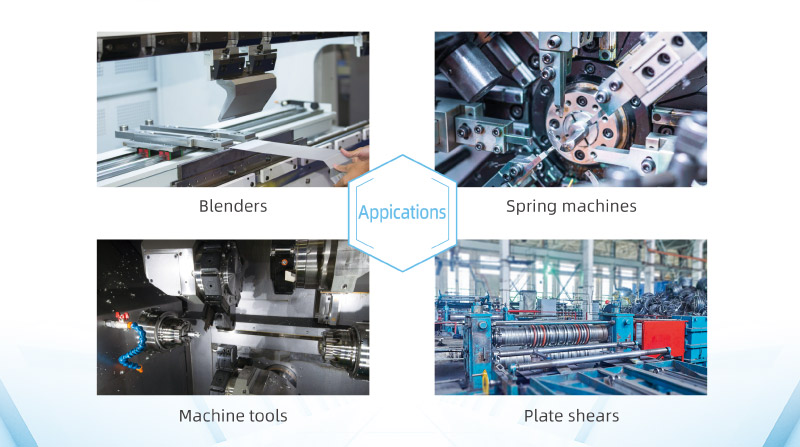

Industrial Applications for V9E Series General Servo Motor

Applications:Semiconductors, 3C, SMT, PCB inspection, auto production lines, packing machines, turn-mill combination, winding machines, wood machines, laser cutting, textile machines, glass machines, blenders, spring machines, machine tools, plate shears.

High-speed ultra-low inertia

Torque range: 0.64~6.4(N-m)

Speed range: 3000~7000(rpm)

High-speed low inertia

Torque range: 0.32~15.9 (Nm)

Rated speed: 3000 (rpm)

Max.speed: 5000/6000/7000(rpm)

Medium-speed medium-inertia

Torque range: 4.8~35.8(N·m)

Rated speed: 2000/3000(rpm)

Max.speed: 4000/5000(rpm)

Medium-speed large-inertia

Torque range: 5.4~47.8(N·m)

Rated speed: 1500(rpm)

Max.speed: 3000/4000(rpm)

Specifications

| Model Type | High-speed ultra-low inertia Torque range: 0.64~3.2N.m Speed range: 3000~7000rpm High-speed low inertia Torque range: 0.32~15.9N.m Rated speed: 3000rpm Max.speed: 5000/6000/7000rpm Medium-speed medium-inertia Torque range: 4.8~35.8N.m Rated speed: 2000/3000rpm Max.speed: 4000/5000rpm Medium-speed large-inertia Torque range: 5.4~47.8N.m Rated speed: 1500rpm Max.speed: 3000/4000rpm |

|---|---|

| Work pattern | S1(Continuous) |

| Insulation resistor | DC500V,5GΩ or above |

| Excitation | Flange |

| Insulation level | F |

| Insulation voltage | AC1500V 1min (220V); AC1800V 1min (380V) |

| Protection level | IP67(excluding the axis extension end) |

| Forward rotation | The servo drive defaults to a forward command that rotates counterclockwise (CCW) when viewed from the axis extension side |

| Environment | Working temperature: -15℃~40℃ (not freezing) (Please refer to the derating curve for use over 40℃) Working humidity: 20%~80%(No condensation) |

| Impact strength | Impact acceleration: 490m/s² (based on flange-side) Impact No.: 2 |

| Vibration strength | Vibration acceleration: 49m/s² (based on flange-side) |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| V9E General Servo Motor Catalog | Catalog | English | 2025-10-11 | 8.66MB | |

| CE (EMC) of V9E Servo Motor-1 | Certificate | English | 2024-08-06 | 4.19MB | |

| CE (EMC) of V9E Servo Motor-2 | Certificate | English | 2024-08-06 | 2.67MB | |

| CE (EMC) of V9E Servo Motor-3 | Certificate | English | 2024-08-06 | 4.24MB | |

| CE (EMC) of V9E Servo Motor-4 | Certificate | English | 2024-08-06 | 2.51MB | |

| CE (LVD) of V9E Servo Motor-1 | Certificate | English | 2024-08-05 | 6.8MB | |

| CE (LVD) of V9E Servo Motor-2 | Certificate | English | 2024-08-05 | 6.66MB | |

| SD Series Servo Drive Selection Software V1.2.2 | Software | English | ZIP | 2025-08-11 | 705KB |

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message