- Home > Product > Motion Control > AC Servo System > SD810 Series General Multi-Drive Servo System

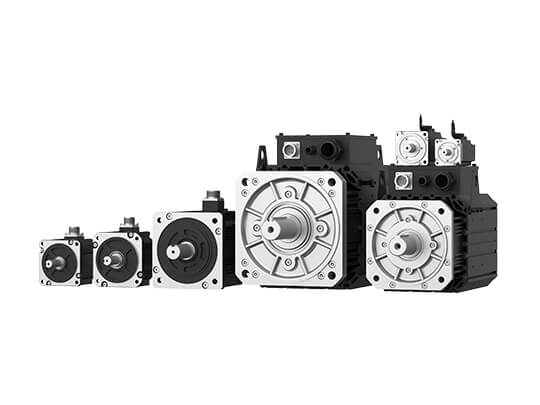

SD810 Series General Multi-Drive Servo System

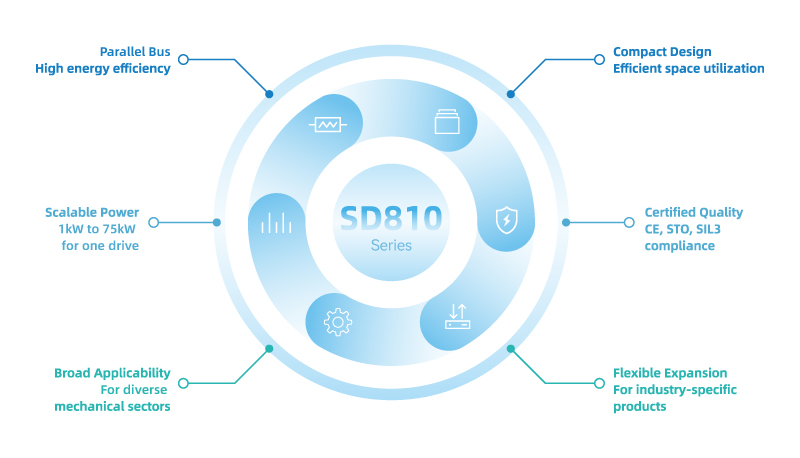

- Parallel bus high energy efficiency.

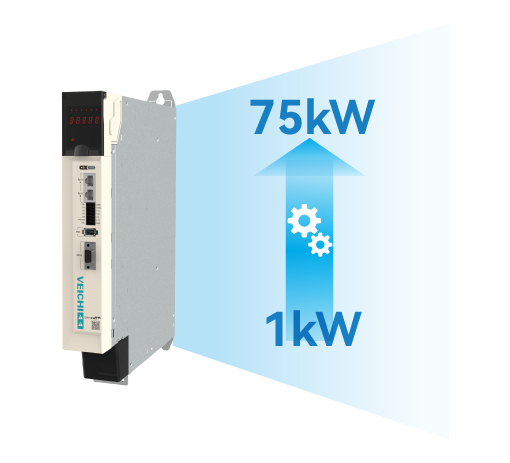

- Scalable power 1kW to 75kW for one drive.

- Broad applicability for diverse mechanical sectors.

- Compact design efficient space utilization.

- Certified quality STO, SIL3 compliance.

- Flexible expansion for industry-specific products.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

Product Introduction

Veichi's SD810 series multifunctional servo platform offers efficient solutions for industrial machinery across injection molding, die-casting, bending, manipulator, forging tool, turret punch press, steel cutting, and handling equipment.

It boasts easy one-touch adjustment, an adaptive notch filter, torque compensation, and a reliable, compact design, simplifying installation, power/wiring distribution, and maintenance for a better user experience.

High Energy Efficiency

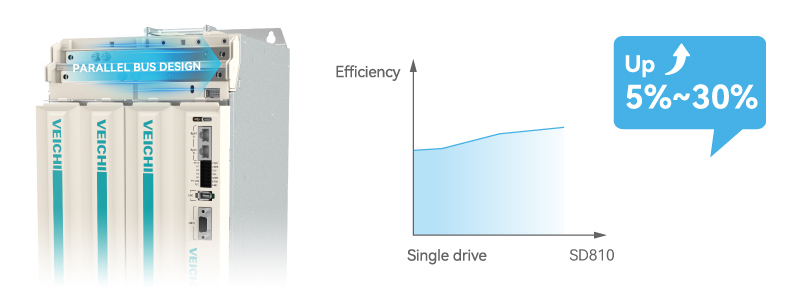

Parallel bus boosts efficiency, reducing energy by 5%-30% than one drive and eliminating braking resistance needs.

Space-Efficient Design

Wide Power Range

Comprehensive Protection

STO, SIL3 complianceFlexible Expansion

For developing industry-specific products;

Supports third-party motors.

Extensive Application

Spanning various industries such as injection molding, die-casting, bending, manipulator, forging, punch press, metal cutting, and material handling.

Precise Positioning

Standard with a 23-bit absolute encoder,upgradeable to a higher precision encoder upon request.

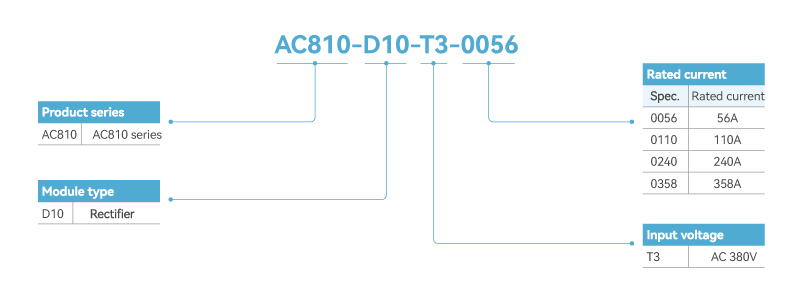

Rectifier Module Naming

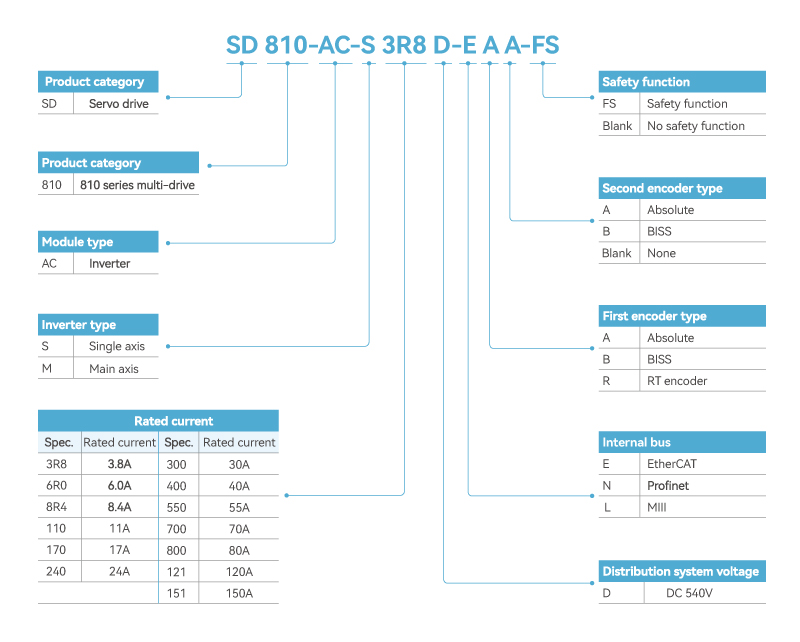

Inverter Module Naming

Specifications

| Basic parameters |

Grid voltage: Three-phase 380VAC~480VAC (-15%~+10%) Power range: Rectifier unit: 45kW, 110kW, 160kW Grid type: TN, TT, IT star topology Input frequency: 50Hz/60Hz(47Hz~63Hz) Braking: Add braking module and braking resistor |

|---|---|

| Customization | Comm./Bus Modbus-RTU: 115200 max. baud rate, 128 nodes, 1000m max distance Profibus-DP (optional): 12M max. rate, 32 nodes, 100m max distance CANopen: 1M max. rate, 64 nodes, 40m max distance PROFINET: 100M max. rate, 100m max distance |

| HMI | DI, DO/Display: 1-channel multi-function input terminal, isolated drain/source programmable terminal with working voltage from 9V to 30V, invalid below 5V. 3kΩ input impedance, compatible with 100Hz inputs. 3-channel relay output with programmable normally open and closed contacts. |

| Protection | Protects against temperature, phase loss, voltage imbalance, over-voltage, brake circuit over-current, resistor short-circuits, and brake tube blocking |

| Environment | IP: IP20 Cooling: Forced air-cooling Temperature Operating: -10°C to 50°C, air temp change < 0.5°C/min; derate use at 40°C+, 1.5% current derate per °C increase, max 50°C. Storage: -25°C to 70°C. Transport: -25°C to 70°C. RH Operating: 5%-95% humidity, not suitable for corrosive gas environments Storage: 5%-95% relative humidity Transport: <95% relative humidity at +40°C Altitude: Up to 1,000m with a 1% rate reduction for each additional 100m, max. at 3,000m |

| Control | IGBT PWM controlled sinusoidal current drive mode |

|---|---|

| Feedback | Rotary servo motor: Serial encoder: 17-bit, 23-bit, 24-bit, 25-bit multi-turn absolute encoder, rotary transformer Linear servo motor: Incremental scale, parallel signals |

| Environment | Ambient temp. Operating: -10℃~50℃, <0.5℃/min air temp. change, derates 1.5% per °C above 40℃, max 50℃ Storage temp.: -20℃~70℃ Ambient humidity: Below 95%RH (no freezing or condensation) Storage humidity: Below 95%RH (no freezing or condensation) Vibration resistance: 4.9m/s2 Impact resistance: 19.6m/s2 IP: IP20 (when properly installed) Cleanliness: No corrosive or flammable gases No water, oil, chemicals splash Less dust, dirt, salt and metal powders Altitude: 1,000m, derates 1% per 100m above, max 3,000m |

| Performance | Speed control: 1:5000, stable at rated torque Speed load: Below ±0.01% of rated speed (Load: 0%~100%) Fluctuation rate voltage: Below ±0.01% of rated speed (Voltage: ±10%) Temperature: Below ±0.1% of rated speed (Temp.: 25℃±25℃) Torque control accuracy (reproducibility): ±1% Soft-start time: 0s~30s (for separately set accel./decel.) |

| Communication | Bus (CN6) USB (CN7) |

| Display | CHARGE, 8-segment LED × 5bit |

| Panel Operator | Button switch× 4 |

| Regeneration | External |

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message