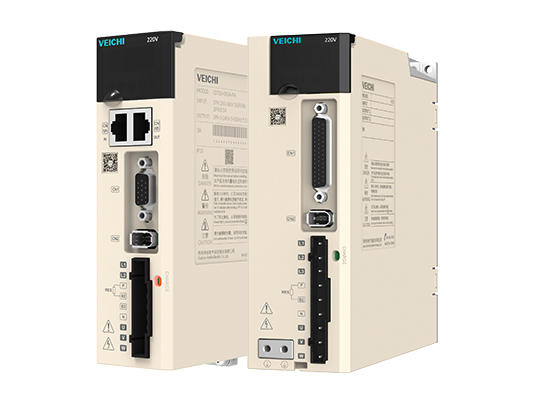

- Home > Product > Motion Control > AC Servo System > SD710 Series General Servo Drive

SD710 Series General Servo Drive

- PC software upgrade;

- Compatible with 17bit/23bit absolute encoder;

- Realize automatic parameter adjustment;

- Upgraded hardware and structure, smaller size;

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

SD710 Series General Servo System Overview

VEICHI SD710 series servo drives are high performance, high reliability, high quality, and cost-effective products to meet a variety of industrial environments and critical system applications and achieve the perfect combination of servo and program.

1. PC software upgrade.

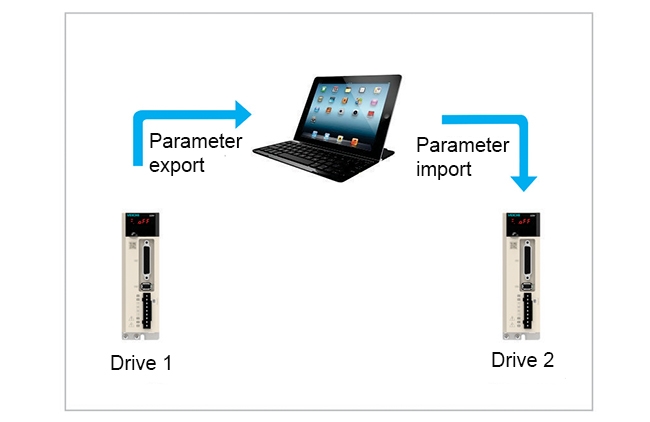

2. Drive parameter copy.

3. Compatible with 17bit/23bit absolute encoder.

4. Continuing the superior performance of VEICHI products.

5. Realize automatic parameter adjustment.

6. Powerful bus communication function.

7. Smart setting.

8. Upgraded hardware and structure, smaller size.

Debug the upper computer upgrade

Convenient and easy-to-use servo debugging upper computer.

The debugging software has the function of copying the drive parameters, eliminating the tedious operation of parameter setting of the same model.

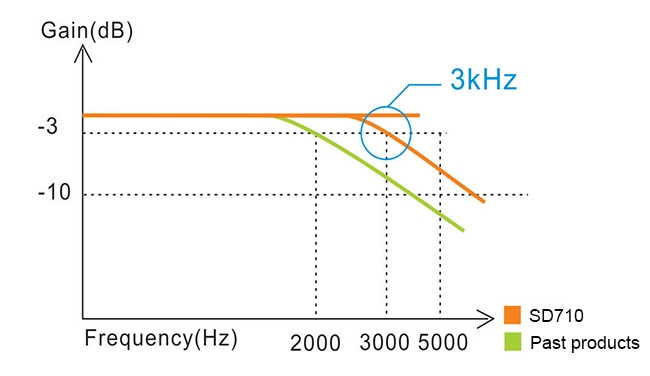

Superior product performance, ultra-high servo response frequency

Powerful bus configuration

1. Standard Micro USB host computer dedicated interface.

2. Standard RS485 communication.

3. Optional Canopen, Ethercat communication.

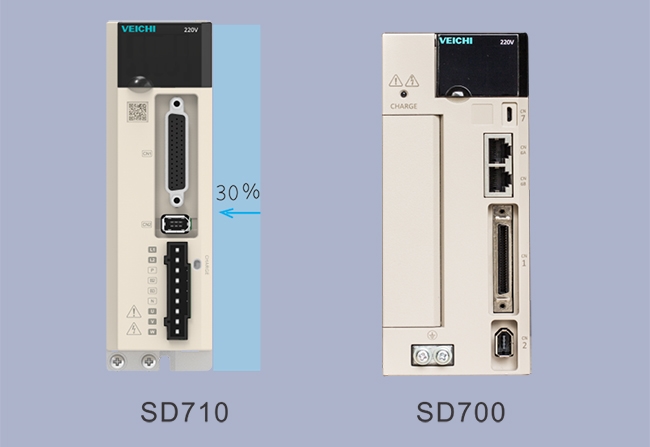

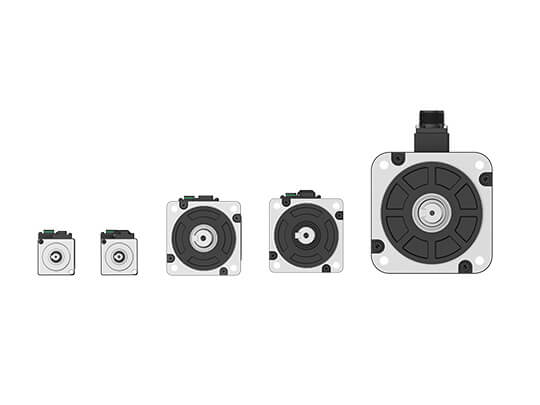

Upgraded hardware and structure, smaller size

Hardware and structure upgrade, 5R5 model volume reduced by 30%.

Mature and stable field application program

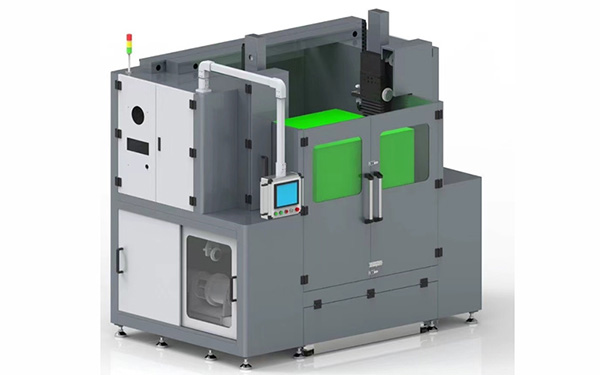

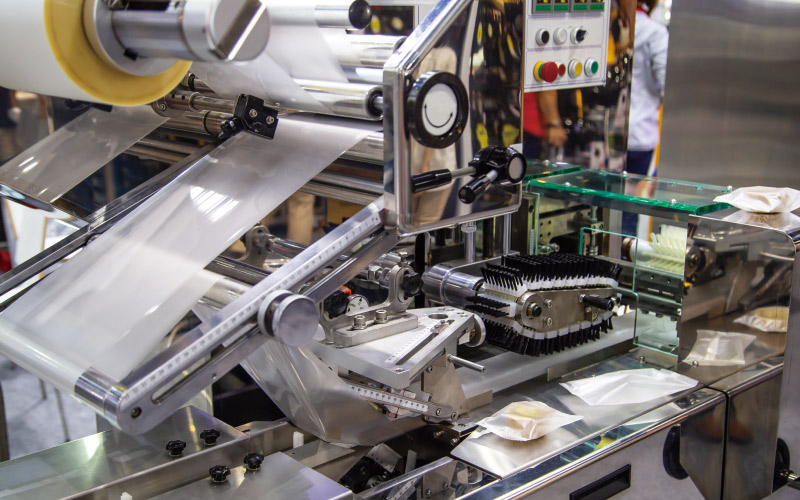

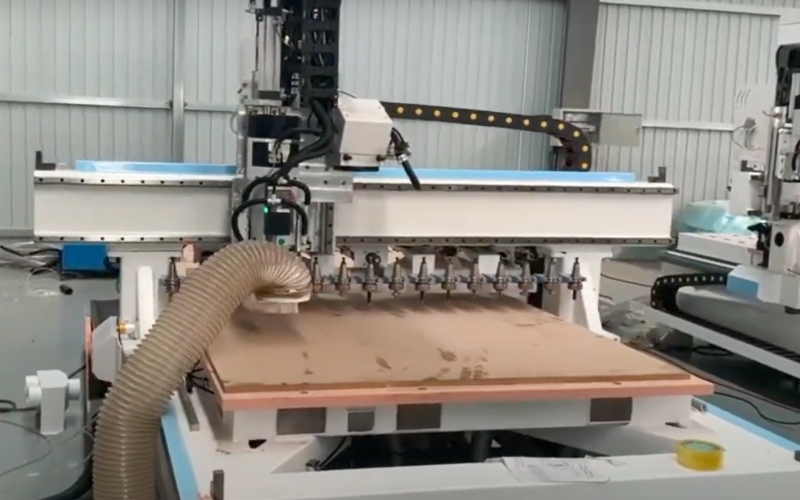

It can be widely used in 3C, lithium battery, woodworking, packaging, manipulator, logistics, food, textile and other automation industry equipment.

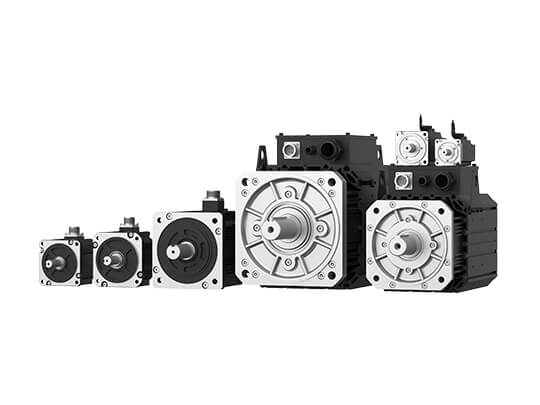

SD710 series servo is compatible with V7E series motor

SD710 Servo Drive Video

Industrial Applications for SD710 Series Universal Servo System

Applications:3C, lithium battery, woodworking, packaging, manipulator, logistics, food, textile and other automation industry equipment.

Specifications

| Encoder feedback | Serial encoder: absolute value encoder |

|---|

| Operating temperature | 0°C~55°C (55°C~60°C can be used after derating) |

|---|---|

| Storage temperature | -20℃~ 65℃ |

| Operating temperature | Below 95%RH (no freezing and condensation) |

| Storage temperature | Below 95%RH (no freezing and condensation) |

| Shock resistance | 4.9m/s |

| Impact strength | 19.6m/s |

| Protection class | IP20 |

| Altitude | Less than 1000m (1000m-2000m, need to reduce the rated value before use) |

| Other | No electrostatic interference, strong electric field, strong magnetic field, radiation, etc. |

| Speed control range | 1: 5000 (the lower limit in the speed control range is the value under the condition that the rated torque load does not stop) |

|---|---|

| Speed volatility | Load fluctuation:±0.01% or less of rated speed (load fluctuation: 0%~100%) Voltage fluctuation:0% of rated speed (voltage fluctuation: ±10%) Temperature fluctuation:±0.01% or less of rated speed (temperature fluctuation: 25℃±25℃) |

| Torque control accuracy | ±1% (reproducibility) |

|---|---|

| Soft start time setting | 0s~10s (acceleration and deceleration can be set separately) |

| Feedforward compensation | 0%~100% |

|---|---|

| Command pulse | Command pulse shape:Including "pulse + direction", "CW + CCW pulse sequence", "A, B phase quadrature pulse" three command forms Input form:Linear drive, open collector Maximum input frequency:Differential Input: High Speed Max 4Mpps; Open Collector: Max 200Kpps |

| 485 | Standard |

|---|---|

| CAN | Optional |

| USB | Computer host computer, standard configuration, in line with USB2.0 specification (12Mpps) |

| Display function | CHARGE, 8-segment LED*5 digits |

|---|

| Panel operator function | Button switch*4 |

|---|

| Regeneration | Function can be built-in/external |

|---|

| Display function | Overcurrent, overvoltage, undervoltage, overload, regeneration fault, encoder disconnection, overtravel protection, etc. |

|---|

| Accessibility | Gain adjustment, alarm recording, JOG operation, etc. |

|---|

| Encoder pulse frequency division output | Phase A, Phase B, Phase C: Linear drive output, frequency-divided pulse number: 35~32767 |

|---|

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| SD710 General Servo Drive Catalog | Catalog | English | 2024-12-04 | 8.61MB | |

| SD Series Servo Drive Solution Catalog for Machine Tool Industry | Catalog | English | 2019-04-17 | 10MB | |

| CE (EMC) of SD710 Servo Drive (Size A Non-standard Included) | Certificate | English | 2024-07-29 | 766KB | |

| CE (LVD) of SD710 Servo Drive (Size A Non-standard Included) | Certificate | English | 2024-07-29 | 758KB | |

| CE (EMC) of SD710 Servo Drive (Size A) | Certificate | English | 2024-07-29 | 727KB | |

| CE (LVD) of SD710 Servo Drive (Size A) | Certificate | English | 2024-07-29 | 701KB | |

| CE (EMC) of SD710 Servo Drive (Size B) | Certificate | English | 2024-07-29 | 2.14MB | |

| CE (LVD) of SD710 Servo Drive (Size B) | Certificate | English | 2024-07-29 | 2.12MB | |

| CE (EMC) of SD710 Servo Drive | Certificate | English | 2024-07-19 | 766KB | |

| CE (LVD) of SD710 Servo Drive | Certificate | English | 2024-07-19 | 758KB | |

| SD710 Series Servo Drive EPLAN Data | EPLAN | English | ZIP | 2024-12-16 | 335MB |

| SD710 Series Servo Drive Manual V1.0 | Manual | English | 2022-01-27 | 12.8MB | |

| SD Series Servo Drive PC Software V1.12.18 | Software | English | ZIP | 2025-08-18 | 40.1MB |

| SD Series Servo Drive Selection Software V1.2.2 | Software | English | ZIP | 2025-08-11 | 705KB |

| SD710 Servo Drive Ethercat Software V1.0 | Software | English | ZIP | 2024-05-22 | 14KB |

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message