Servo Press Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Servo Press Solution

Punch forming utilizes presses and molds to exert external force on materials such as plates, strips, tubes, and section bars, resulting in plastic deformation or separation. This process produces workpieces (stamped parts) with the desired shape and size. Compared to traditional presses, servo presses are known for their flexible operation and improved stability, gaining increased preference in the market.

Features and Benefits

System Function

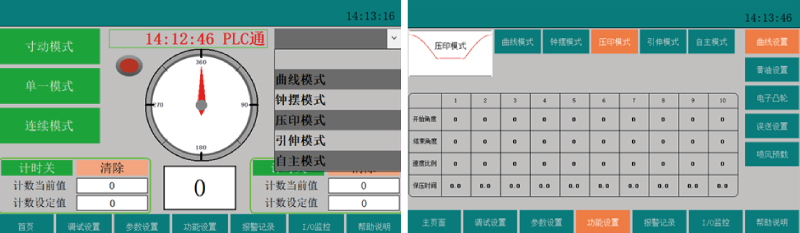

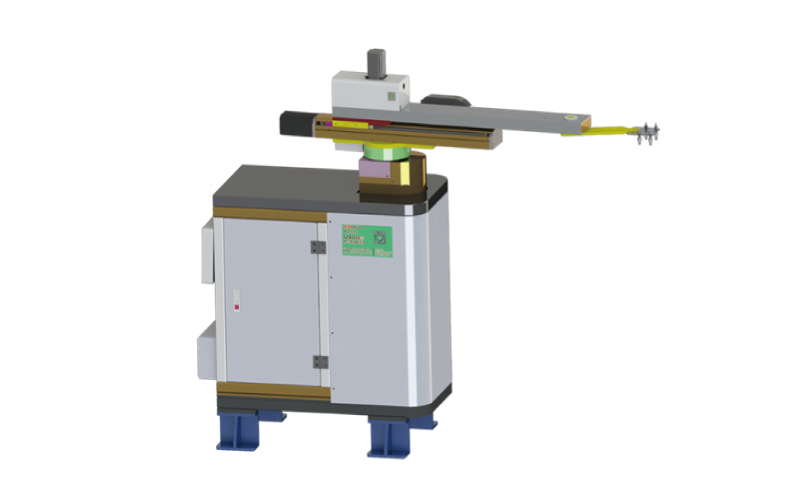

The servo press, driven by a servo motor, applies the motor's force into the slider's linear motion via a crankshaft linkage, catering to various intelligent pressing needs. Its operation modes include:

Crankshaft Mode

The servo motor cycles in one direction at a fixed speed.

Half-travel Mode

The servo motor reciprocates back and forth at a set angle.

Stamp/Draw Mode

The servo motor starts, stops, and operates at varying speeds and angles; the pressure maintaining time is adjustable based on process requirements.

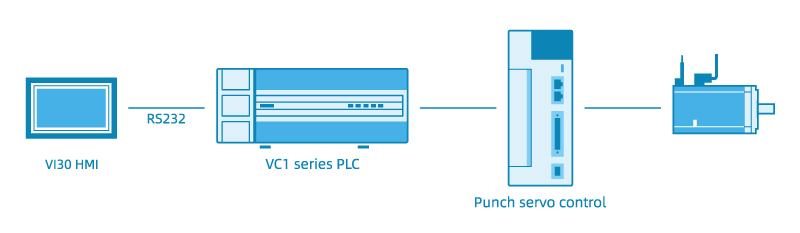

System Topology

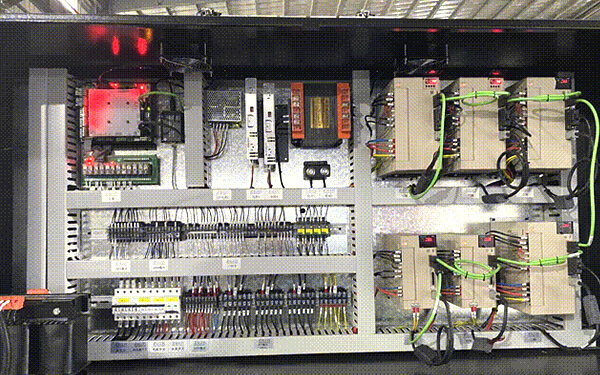

VEICHI has introduced a servo press solution based on its industry knowledge for customer needs, via the propriety VC1 PLC and SD700 servo drive for quick and precise control.

System Feature

VI30 HMI

Features main interface displaying alarms and yields, function buttons for manual control, and a settings interface for process control and position parameters. It also supports IoT for remote control.

VC1 PLC

Enables the analysis and setting of HMI data, so as to precisely control the whole system.

Conclusion

VEICHI's servo press control system embraces the smart press era, offering significant improvements over traditional models by allowing variable speed and dwell time at any angle, and enhancing punching accuracy, product quality, and extends the lifespan of abrasive tools. The integration of VEICHI's VC1 PLC with the SD700 high-performance servo drive ensures fast, precise, and responsive control at great cost efficiency. It supports various operation modes such as crankshaft, half-travel, press, and draw to meet diverse needs. With all features above, VEICHI's servo press control system is an ideal solution characterized by impressive efficiency, stability, and innovation.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message