Programmable Punch Feeding Manipulator Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

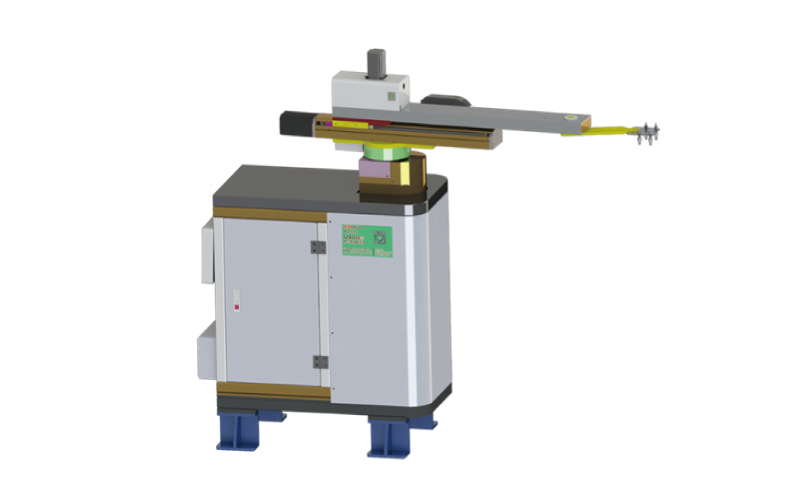

Programmable Punch Feeding Manipulator Solution

The dual-axis programmable punch feeding manipulator, extensively used in automated pressing operations, can be programmed to execute various pressing tasks. This manipulator boosts both efficiency and safety by substituting traditional manual material handling in the pressing process.

Features and Benefits

System Feature

Impressive Dexterity

Dual-axis programmable punch feeding manipulators provide great programming flexibility, easily performing tasks like shearing, piercing, forming, bending and other pressing operations.

High Speed

The dual-axis programmable punch feeding manipulators excel in high-speed operations, significantly boosting productivity and yield by streamlining pressing operations and reducing cycle times.

Safety Function

The manipulator is equipped with comprehensive safety functions, including built-in mechanisms such as a collision sensor, an emergency stop button, and a protective barrier, to reduce risks in operation.

Low Cost

Introducing a two-axis programmable punch feeding manipulator can save costs through automation of the pressing process, reducing labor expenses, and enhancing productivity to minimize material waste and rework.

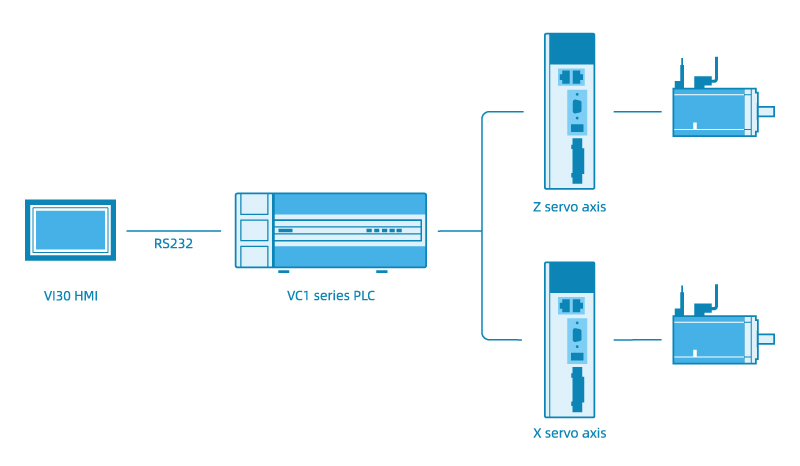

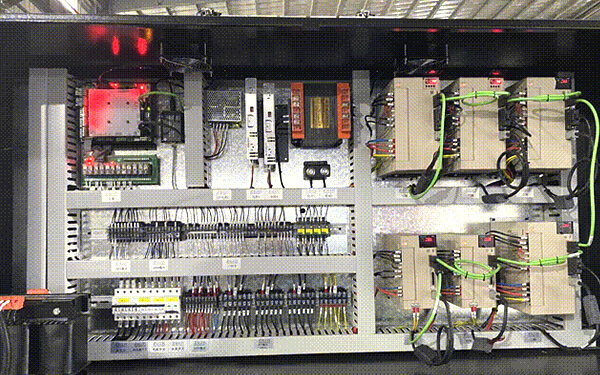

System Topology

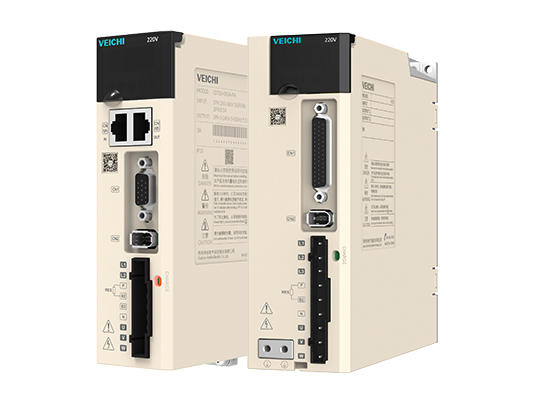

The control system employs our VC1 controller, supporting up to three-axis pulse output with 485 communication and 3-channel 100KHz pulse output, offering strong performance with great cost efficiency. The SD710 model, upgraded in hardware and structure for servo control, reduces the 5R5 model's size by 30%, supports 17bit/23bit absolute encoders, and offers a response frequency of up to 3.0kHz for quicker dynamic response and stable speed.

Conclusion

VEICHI's advanced dual-axis programmable punch feeding manipulator system, powered by our high-performance SD700 Servo System with a 3.0kHz response frequency and 23-bit precision encoder, alongside our versatile PLC products, delivers superior performance.

VEICHI's servo technology offers flexible programming for tasks such as shearing, piercing, forming, and bending, increasing production flexibility and offering a versatile solution for manufacturers to address diverse needs. VEICHI has successfully launched an advanced 2-axis programmable punch feeding manipulator system, providing a premium solution for the manufacturing industry.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message