Hoop Bending Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Hoop Bending Machine Solution

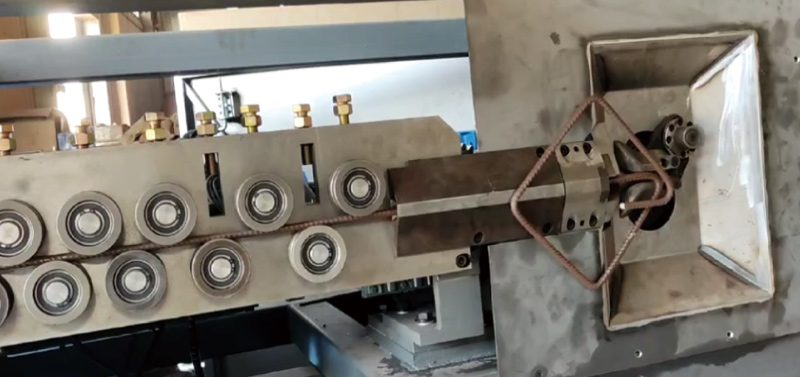

A fully automatic CNC bending machine is mainly used in the processing of materials in the construction industry, and steel bars of various shapes are the most used component on the building construction site. For a long time, it has been made manually by construction workers, which is not only inefficient but also inaccurate. It severely restricted the progress of the construction period and the overall construction quality of the building. With the widespread application of motion control systems, the design of CNC hoop bending machines is finalized, and a large number of CNC hoop bending machines are used in the processing of steel materials in the construction industry. With this equipment, 7.5 tons of steel bars can be processed per shift without occupying a large area. Only one worker is required to work, which is nearly 40 times more efficient than the original manual method.

Features and Benefits

The hoop bender for rebar bending, stands out for its swift operation, precision and efficiency, which can be commonly found in construction sites,reinforced concrete products and rebar processing facilities.

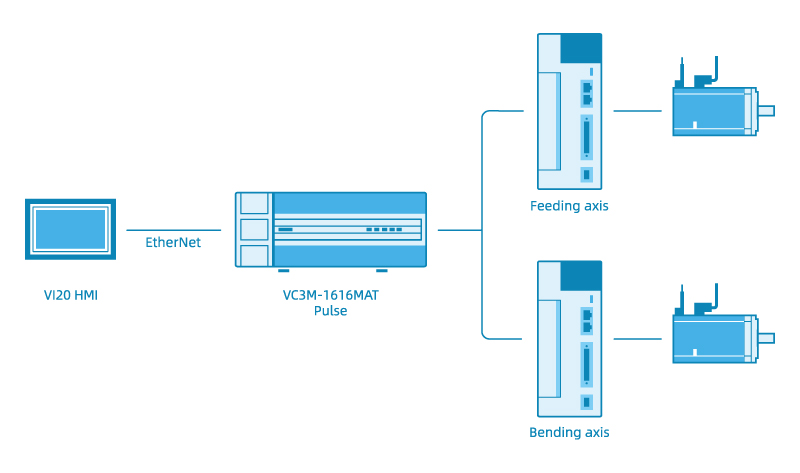

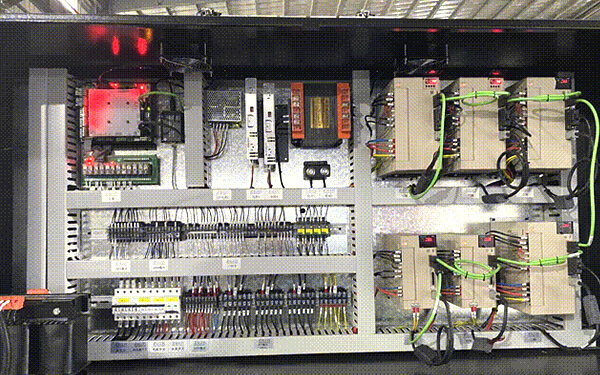

System Topology

1. The control system centers around the VC3 controller, and employs an FPGA + ARM dual-core architecture. It supports up to 8-axis pulse output and functions such as CAN bus, Ethernet communication, electronic cam, interpolation, etc., for machine tools, textiles, packaging, plastics, steel, medical fields and more.

2. The VI20 touch screen system boasts extensive storage, comprehensive features, and quick responsiveness, supporting HMI canvas, macro calculation, formulated storage, real-time alarm monitoring, and alarm data storage, etc. and Screen-to-PLC communication via Ethernet ensures swift and stable data exchange.

3. The Servo System employs full closed-loop control to prevent feed slippage and air cooling with high cooling performance and reduced operation failures.

System Feature

Custom Graphic

Customize graphics like arcs and angles and save them in a graphic library. Up to 32 parameter sets to each graphic allow 32 bends with positive or negative angles. Retraction on the graphic is supported.

Plentiful Templates

Easy operation. To create a five-pointed star shape, user only needs to input the edge length into the template instead of entering multiple data.

Simple Operation

Graphic parameter changes are autosaved in the PLC in the manual mode, but not in the auto mode.

Multi-Tasking

Multi-task mode handles up to 10 unique graphics at once. Multiple rebar shapes can be processed at one time and divided for further handling, allowing task switching, data viewing and editing at any time.

Automatic Compensation

Automatic compensation for angular deviation.

One-Click Reset

Ideal for end environments with high staff turnover, prevent operational errors by restoring mechanical and process default parameters.

Comprehensive Capabilities

Order-based stopping and order count detection.

Manual Control

Basic manual control for I/O and alarm monitoring, alarm log viewing, and one-click reset function.

Enhanced Storage

Storage function for up to 100 graphics allowing smooth browsing and retrieval from the gallery, outperforming current market devices.

Dynamic Password

Dynamic password lock for any time required. Schedule the next period after unlocking.

Conclusion

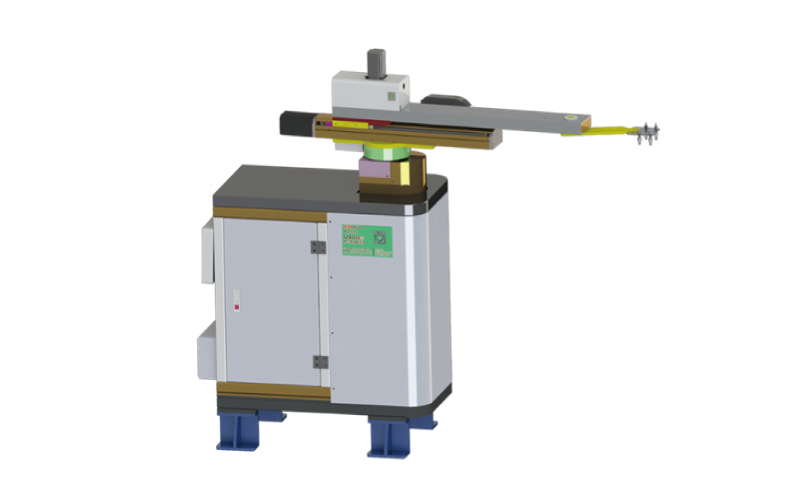

VEICHI's hoop bending machine solution features proprietary PLC controllers, servo drives, AC drives, and servo motors, delivering high efficiency, stability, and strong anti-interference, with multiple functions and straightforward debugging. Tailored to customer needs, the system includes reserved debugging functions and accommodates updates and modifications. Its advanced HMI canvas allows for real-time settings and visual bending shape tweaks, simplifying adjustment.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message