Powder Metallurgy Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Powder Metallurgy Machine Solution

China's high-end manufacturing growth brings along the enhancing role for technology-intensive and high-value-added new materials, leading to a rapid development phase for the powder metallurgy industry and increasing demand for power metallurgy devices. By the trend, VEICHI is leveraging its expertise in automation to develop specialized solutions like powder metallurgy, ceramics, hard alloys, and magnetic materials, and its products have favored across various fields due to their high processing precision, excellent controllability, and high adaptability.

Features and Benefits

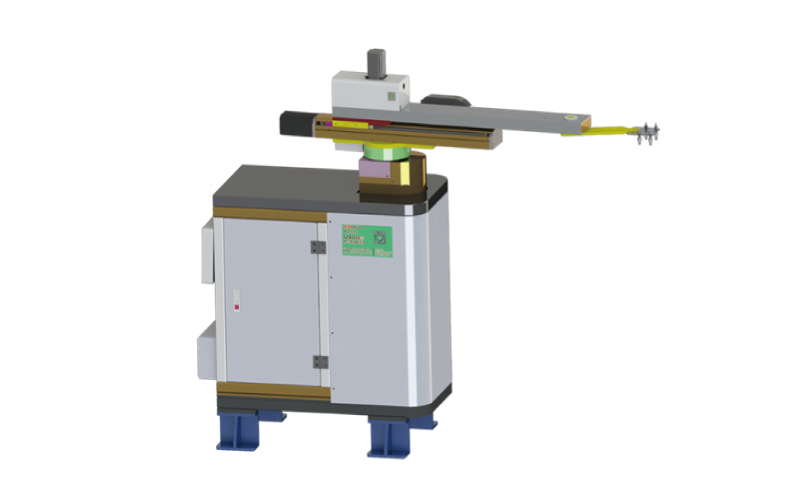

The powder metallurgy Servo System integrates mechanical, electrical, hydraulic, and pneumatic control, and caters to industries like powder metallurgy, ceramics and hard alloy as well as magnetic materials. It allows for pressure setting tailored to molding requirements, which can be generally used for metal and ceramic powder metallurgy.

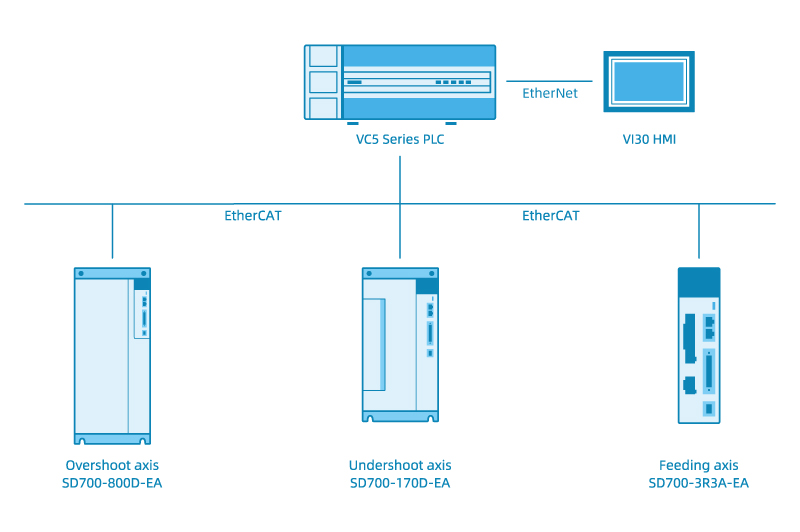

Based on its deep research in applications, VEICHI solution is designed to enhance intelligent levels, production efficiency and yield rates by its advanced integrated control technologies for mechanics, electronics, hydraulics, and pneumatics. The solution of VC5's, the new generation bus high-performance flexible PLC and SD700 series high-performance servo drive, achieves high-precision pressing and significantly improved production efficiency and quality.

In-house Research and Manufacturing for Exceptional Performance

Independent R&D for Greater Compatibility

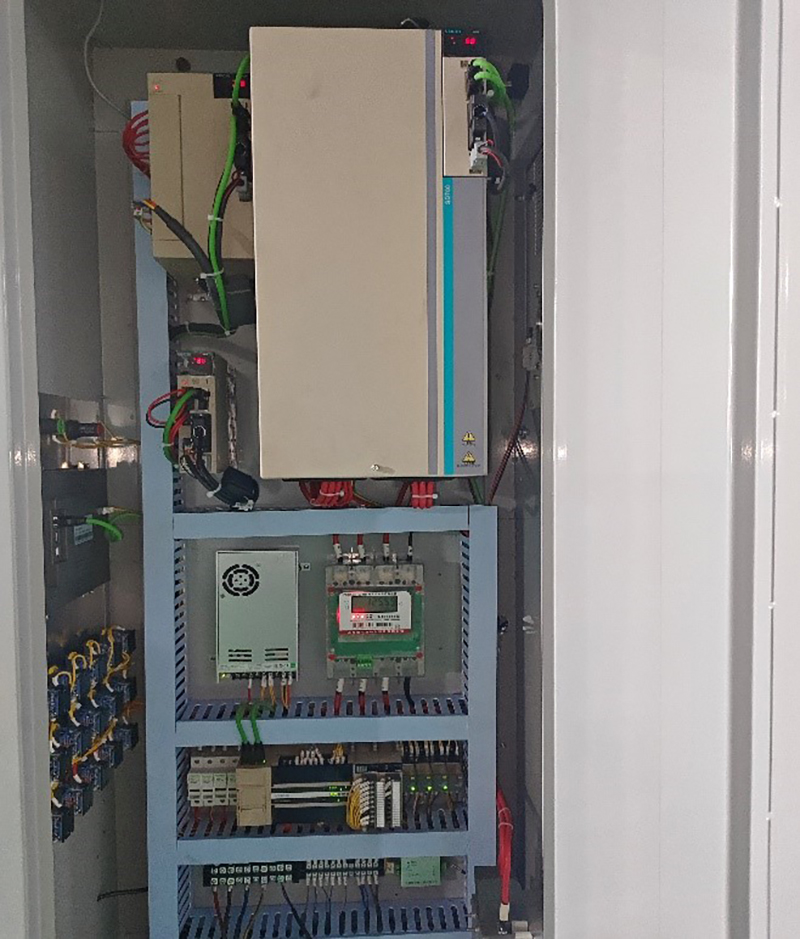

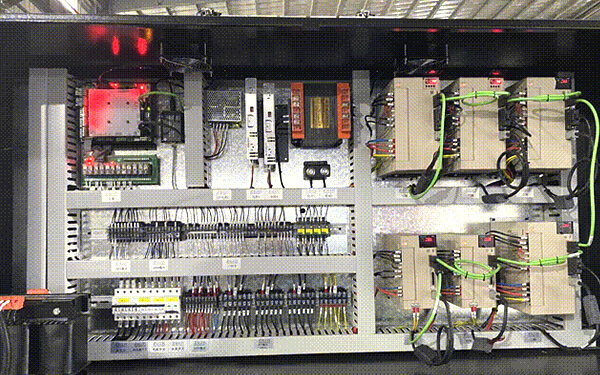

The core products of the system solution are fully developed by VEICHI. The higher stability and compatibility in the products ensures more flexible and trustworthy solutions together with comprehensive after-sales service.

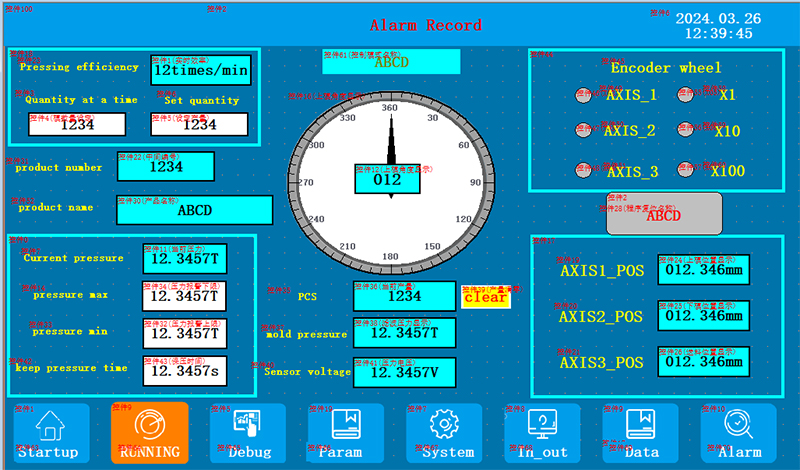

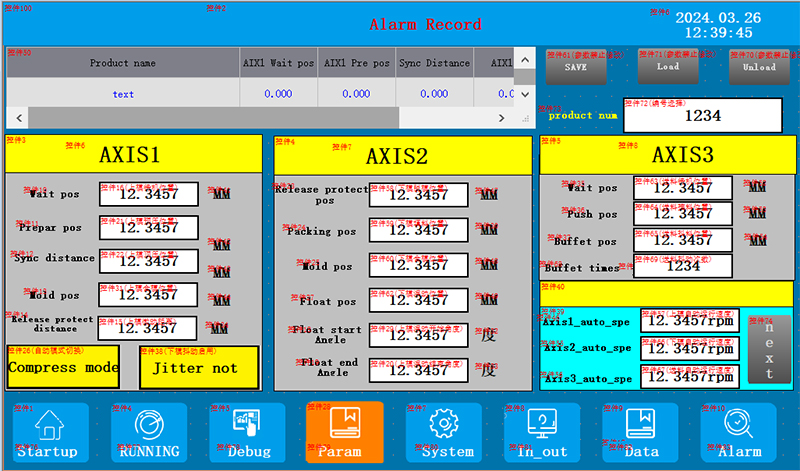

Refined System for Enhanced Adaptability

Products and processes can both be easily set up through a touch screen interface. Besides, it features real-time configuration saving and real-time monitoring of pressure and other parameters. Secondary debugging is eliminated when replacing a new product and it allows for the review of machining data for nearly ten thousand products.

Multiple Modes for Precise Control

Multi-axis and multi-gear adjustment with the handwheel enhances product qualification rates. Press to start and release to stop to immediately observe positions and assess prototype products.

Superior Products for Efficient Combination

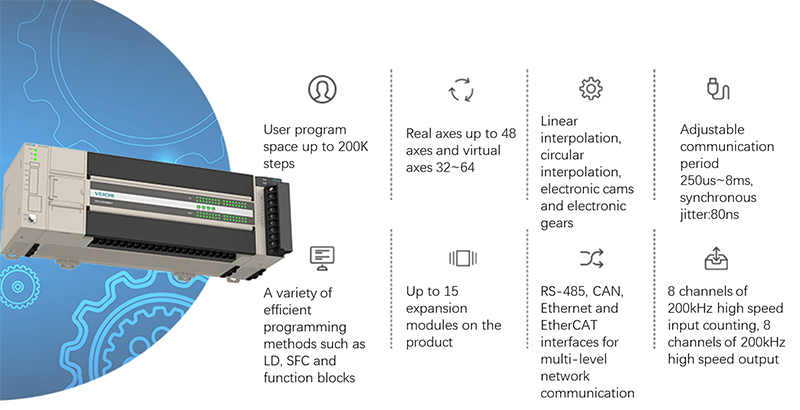

Quick motion control

VEICHI VC5 series is a new generation flexible high-performance bus PLCs with dual-core architecture technology, and supports up to 48 real axes of EtherCAT. Its motion control is rapid with communication cycle at 250μs and synchronization time accuracy of ±80ns to achieve precise pressing.

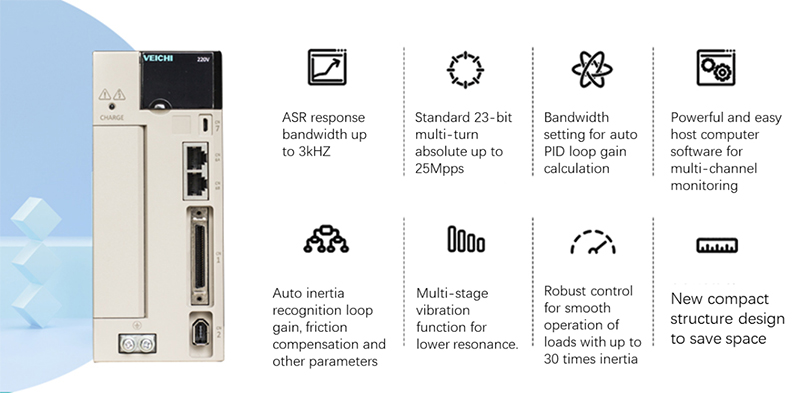

Precise servo drive

VEICHI SD700 series high-performance servo drives offer a response frequency up to 3.0kHz for accurate dynamic response, speed observation, and load inertia recognition during production for higher trajectory tracking accuracy and production efficiency.

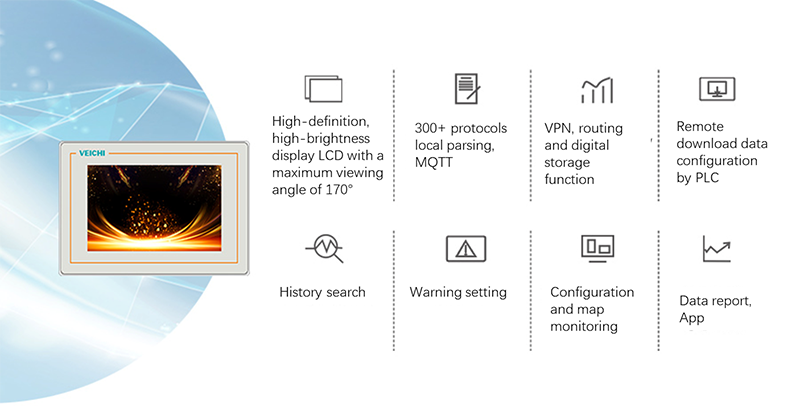

Friendly HMI operations

VEICHI VI30 series touch screens, the new generation of IoT HMI, offer a higher cost-performance ratio due to the higher resolution models and various serial communication options including RS232, RS485, and RS422, applicable to complex industrial control environments requiring more stable and reliable production processes.

VEICHI powder metallurgy solution incorporates advanced electrical control technologies. The flexible setting of the operation program the touch screen enables the pressing and molding of complex shapes and multi-species step parts.

The versatile system ensures the stability and compatibility by adopting VEICHI's high-performance automation products for the whole control system.

Its one-touch setting eliminates redundant re-tuning, while real-time monitoring, multi-axis speed control, and a two-handed debug mode secure a high product success rate. All these features create a comprehensive, mature, and dependable system solution for powder metallurgy machinery.

Amidst the wave of smart manufacturing, VEICHI will keep its efforts to delve deeper into automation, intensify research and innovation and strengthen the technological advantages of its products aiming at the industrial challenges, and continuously improve scenario-based solutions to meet the diversified demands of customers.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message