Laser Tube Cutting Feeder Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Laser Tube Cutting Feeder Solution

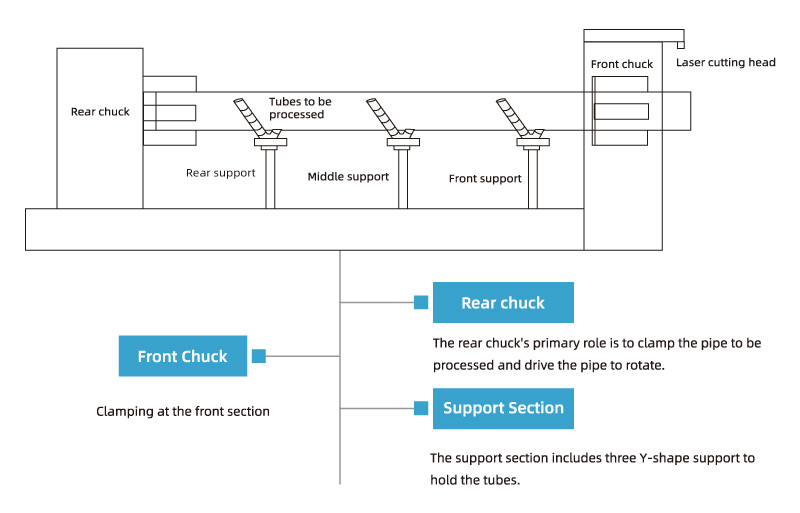

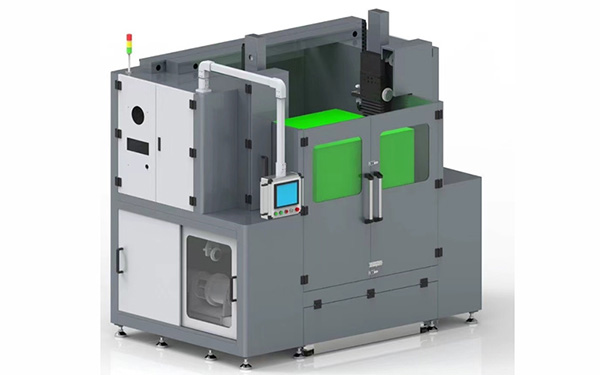

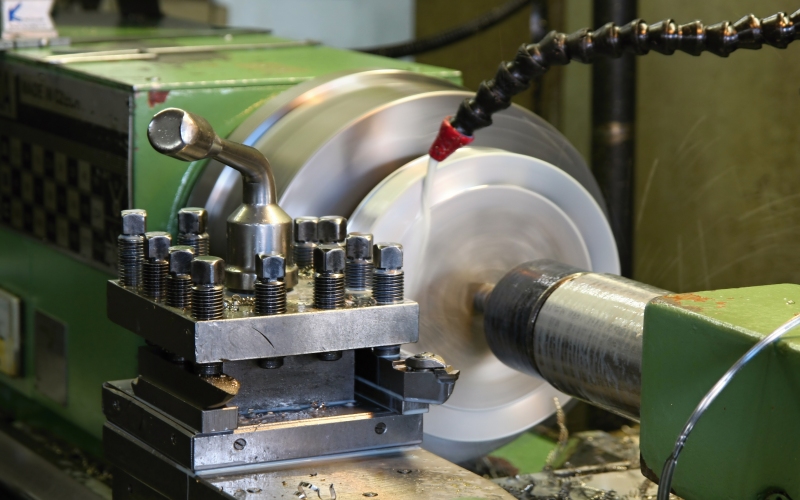

Society progress sees automation advancement, particularly in the steel pipe processing industry. Laser tube cutters offer significantly higher efficiency, accuracy, and safety compared to previous equipment. This section will discuss the application of VEICHI products in the loading mechanisms of laser tube cutting machines.

Features and Benefits

System Feature

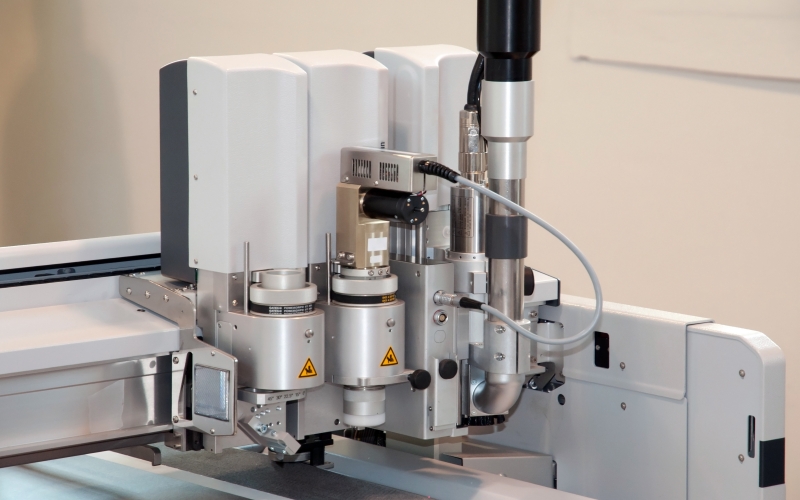

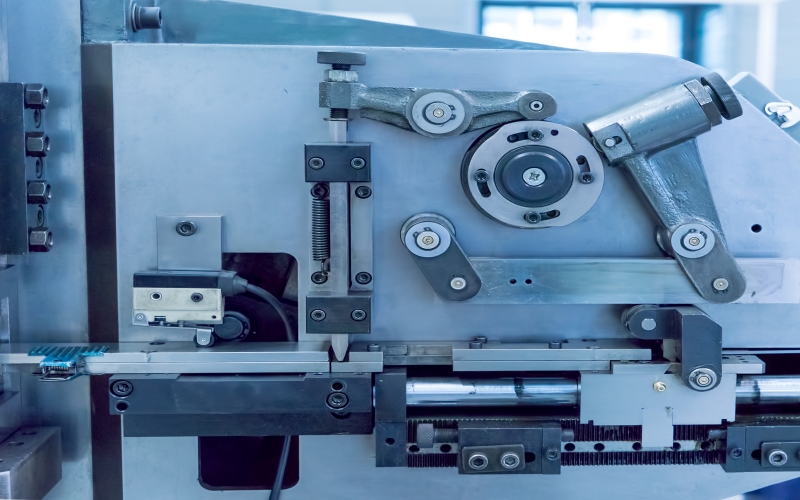

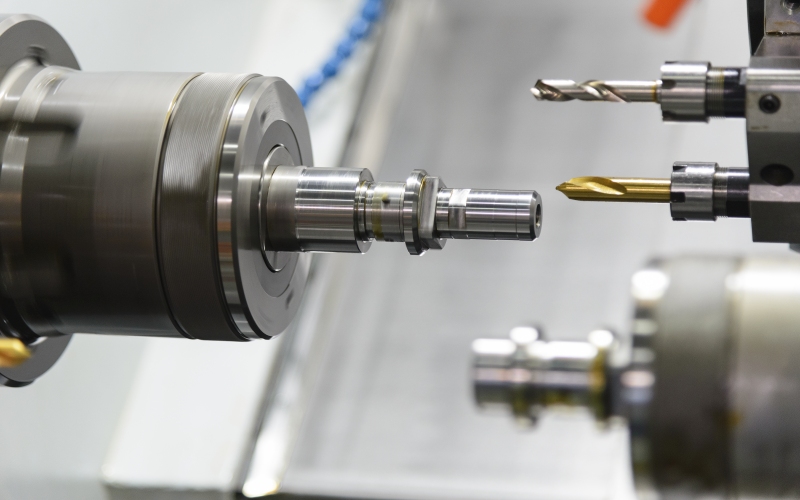

High Precision

Y-shaped support is more effective than traditional arc supports in stabilizing steel tubes. However, their distinct geometry necessitates the calculation of the exact rise height via geometric conversion. The VC3M control system with built-in capabilities for trigonometric calculations, excels in this aspect. Once the rise height implemented, the concentricity across the three axes is maintained within 1mm.

Stable Communication

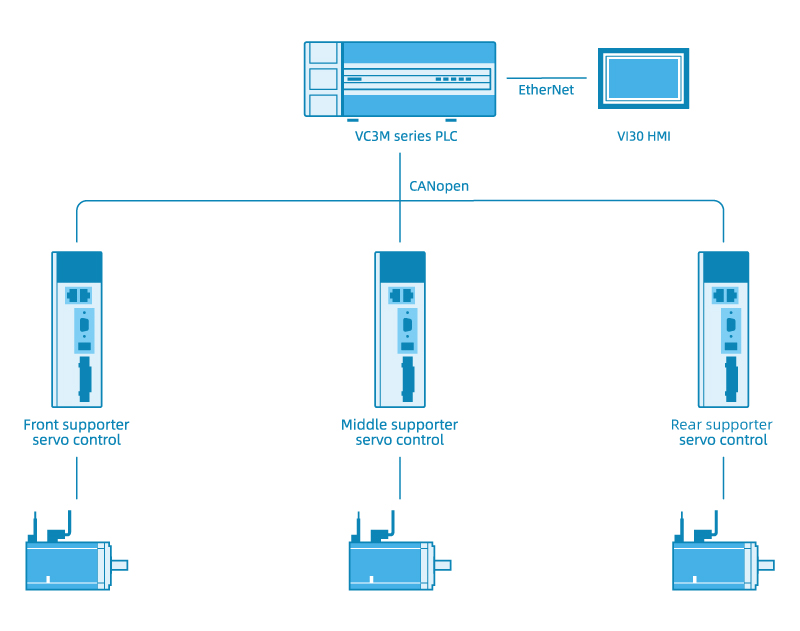

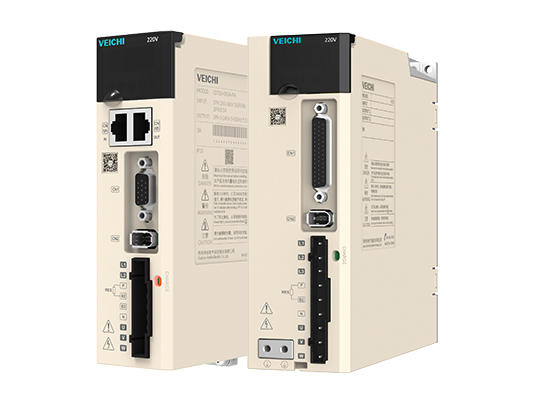

CANopen communication is adopted for VEICHI SD710 and VC3M, ensuring rapid and stable connectivity

Easy Maintenance

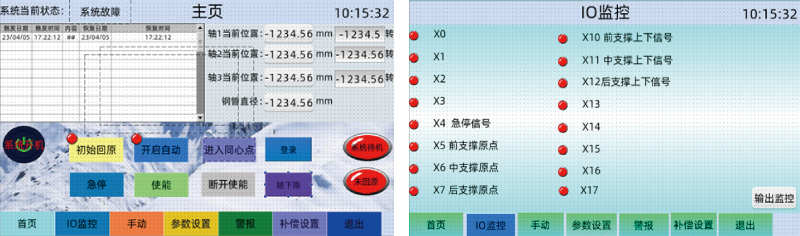

The system is user-friendly; simply input the pipe diameter for it to operate efficiently.

System Structure

System Topology

Conclusion

The VEICHI laser tube cutting feeder system offers high performance with its new Y supports that securely hold steel tubes. It uses advanced VC5 motion control to ensure the concentricity across the three axes is maintained within 1mm, improving accuracy and stability. Between VEICHI SD710 and VC5, the system uses CANopen for fast and reliable communication.It also excels for simple operation which only requires to input the pipe diameter. In general, the unique support design, efficient communication, and simplicity make it a leading user-friendly machining solution.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message