Compound Glue Coater Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

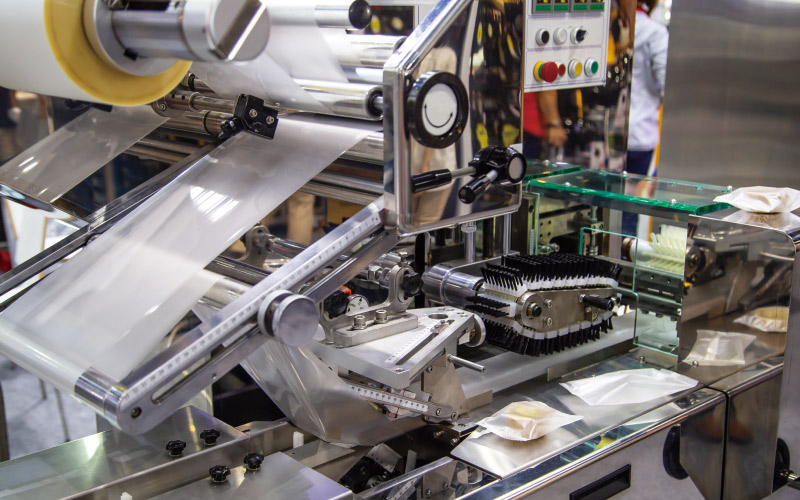

Compound Glue Coater Solution

As society advances and technology progresses, the compound machinery sector within the manufacturing industry is also innovating. Major manufacturers are shifting towards developing high-speed compound glue coaters, phasing out the slower, less reliable, more energy-consuming, and inefficient machines.

Features and Benefits

VEICHI's compound glue coater system showcases its expertise in industry application and product innovation, with the core components including the VC5 motion controller, SD700 servo drive, and AC310 drive system. Thus, by accurately controlling axes like draw, gluing, and winding, it achieves fast, precise, responsive, and stable management.

VEICHI's products enhance the compound glue coater's control system with high efficiency, robust stability, and strong antiinterference capabilities, alongside a wide range of functions. The design includes multiple reversed debugging functions and uses EtherCAT bus communication for synchronized multi-axis positioning, boosting production efficiency and catering to customers' diverse needs. This advanced glue coater solution is broadly applicable across various fields.

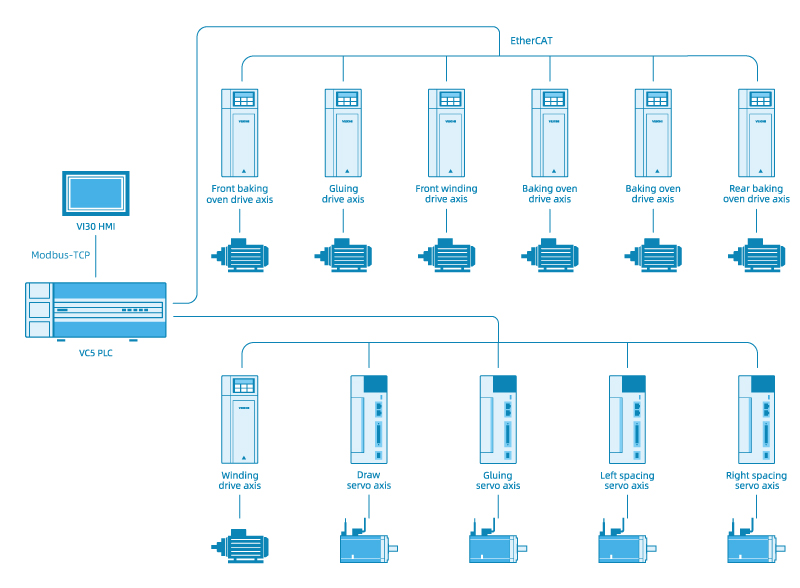

System Topology

VEICHI has introduced a compound glue coater for various customer requirements. Leveraging our extensive industry expertise, this solution integrates VEICHI's VC5 motion controller, SD700 bus high-performance servo drive, and AC310 with PG and EtherCAT cards to control key motion axes including traction, gluing, and winding. It achieves high-speed, precision, responsive, and stable control.

System Structure

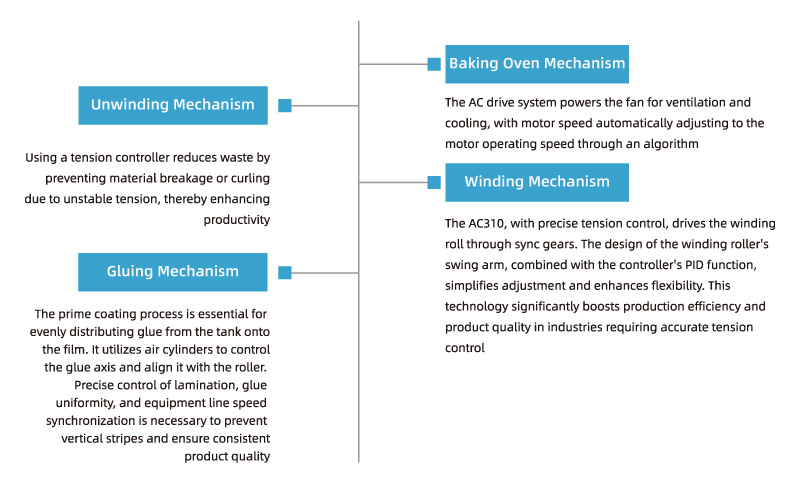

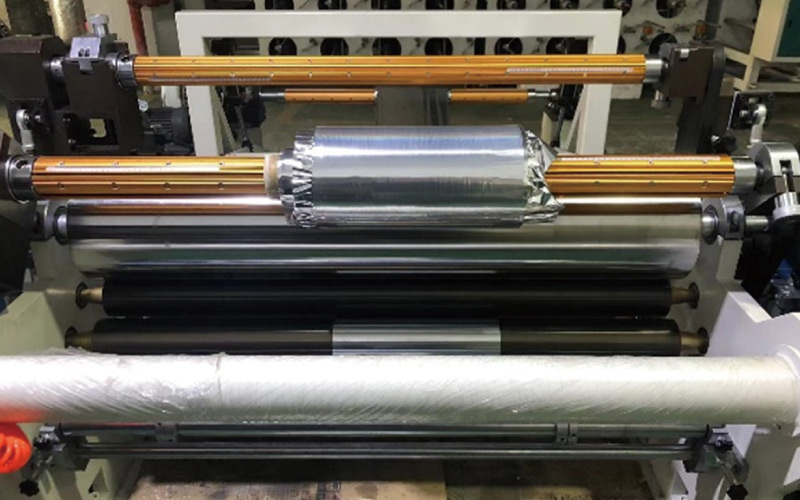

Unwinding Mechanism: Using a tension controller reduces waste by preventing material breakage or curling due to unstable tension, thereby enhancing productivity.

Gluing Mechanism: The prime coating process is essential for evenly distributing glue from the tank onto the film. It utilizes air cylinders to control the glue axis and align it with the roller. Precise control of lamination, glue uniformity, and equipment line speed synchronization is necessary to prevent vertical stripes and ensure consistent product quality.

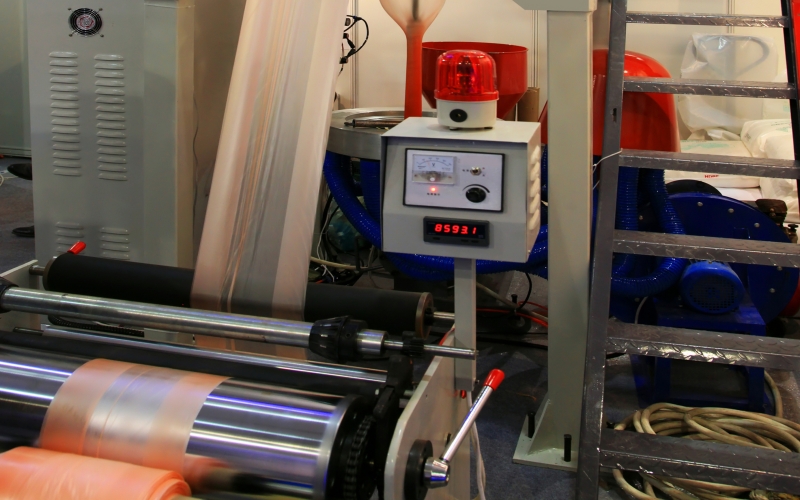

Baking Oven Mechanism: The AC drive system powers the fan for ventilation and cooling, with motor speed automatically adjusting to the motor operating speed through an algorithm.

Winding Mechanism: The AC310, with precise tension control, drives the winding roll through sync gears. The design of the winding roller's swing arm, combined with the controller's PID function, simplifies adjustment and enhances flexibility. This technology significantly boosts production efficiency and

product quality in industries requiring accurate tension control.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message