Fleece Finish Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Fleece Finish Machine Solution

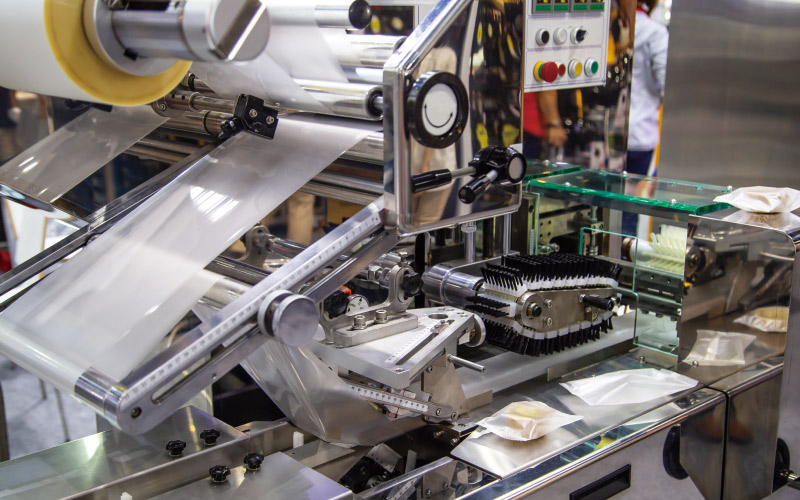

The fleece finishing machine produces a fabric prized for its fluffiness, density, and softness, ideal for warmth, and widely used in sectors across toys and apparel, like casual wear.

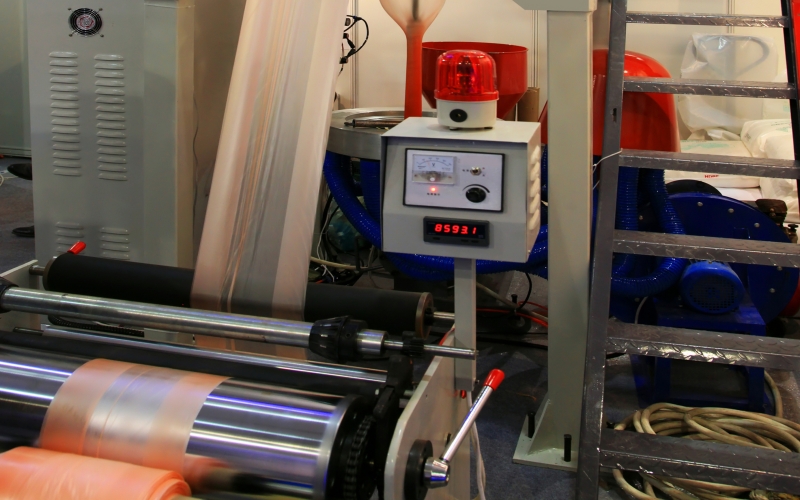

To counteract spinning vibrations that can disrupt the weighing module, a first-order filter is employed to ensure noise-free, stable machine operation. Meanwhile, the automated control of the finish machine leads to labor cost savings and increased production efficiency.

Features and Benefits

The VEICHI fleece machine system excels in fleece finishing with its high-speed, precision, responsiveness, and stability, attributed to the VC3 programmable controller, AC310 high-performance drive, and SD700 high-performance servo drive. Its innovative approach uses a weighing module for finishing roller level control, ensuring polyester threads are neatly aligned and knot-free, reducing the risk of product rejects.

VEICHI fleece finishing system markedly enhances productivity, quality, and automation. It offers a cost-effective, reliable solution for fleece processing, meeting industry demands and bolstering market competitiveness.

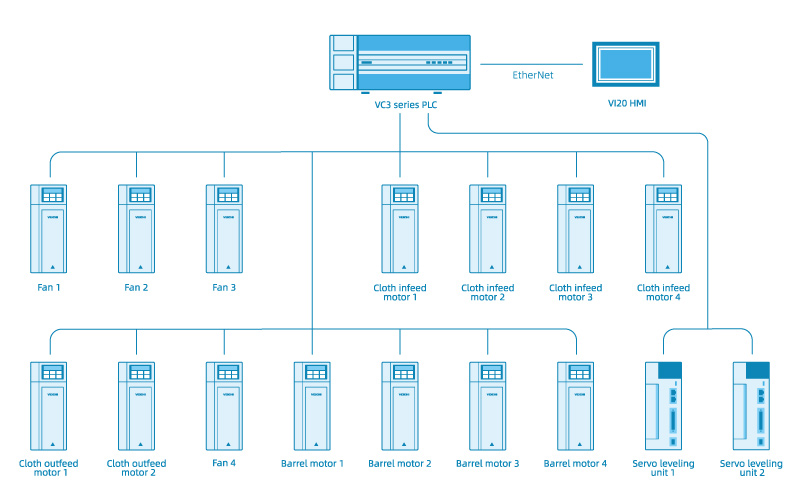

System Topology

System Structure

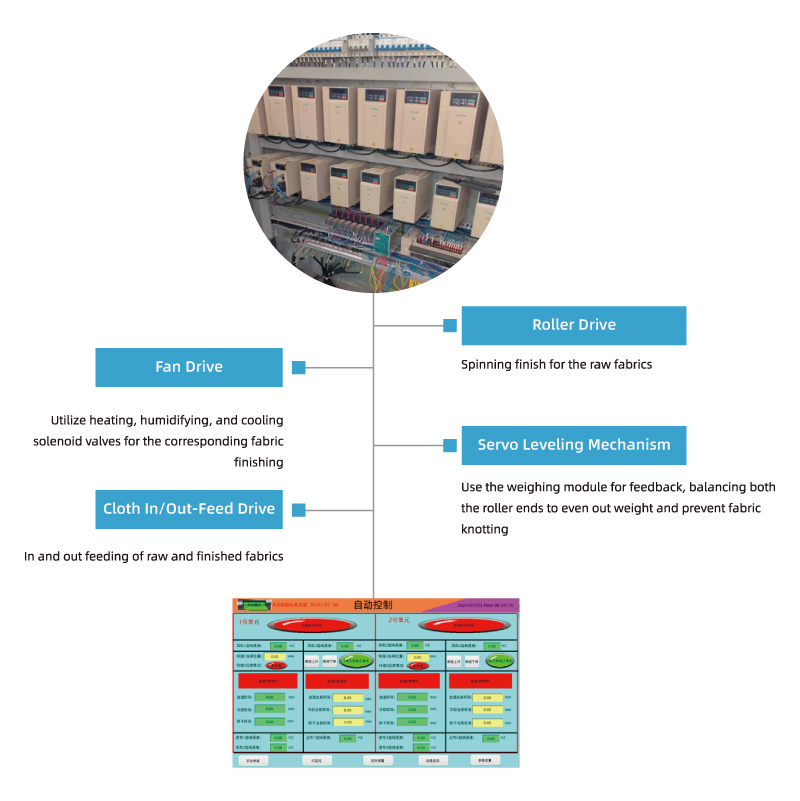

Fan Drive

Utilize heating, humidifying, and cooling solenoid valves for the corresponding fabric finishing.

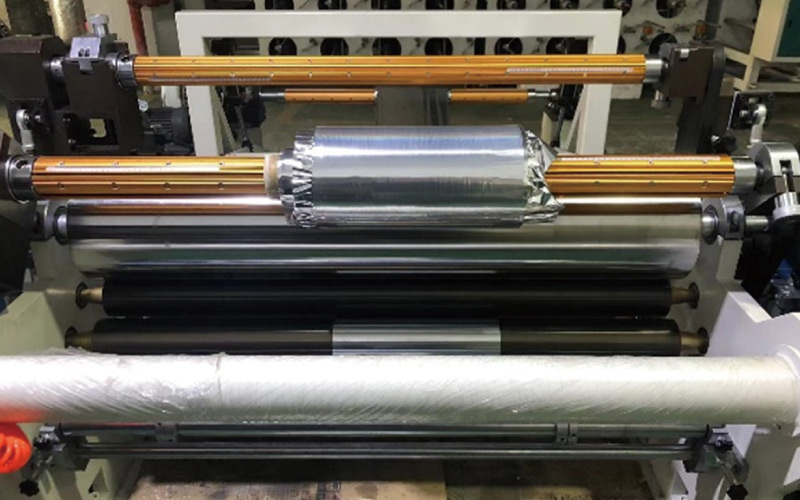

Roller Drive

Spinning finish for the raw fabrics.

Cloth In/Out-Feed Drive

In and out feeding of raw and finished fabrics.

Servo Leveling Mechanism

Use the weighing module for feedback, balancing both the roller ends to even out weight and prevent fabric knotting.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message