Double-Station Coating Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Double-Station Coating Machine Solution

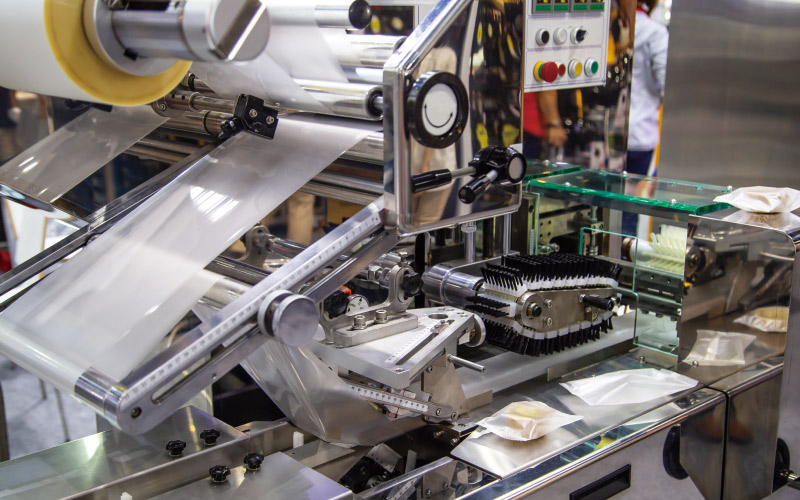

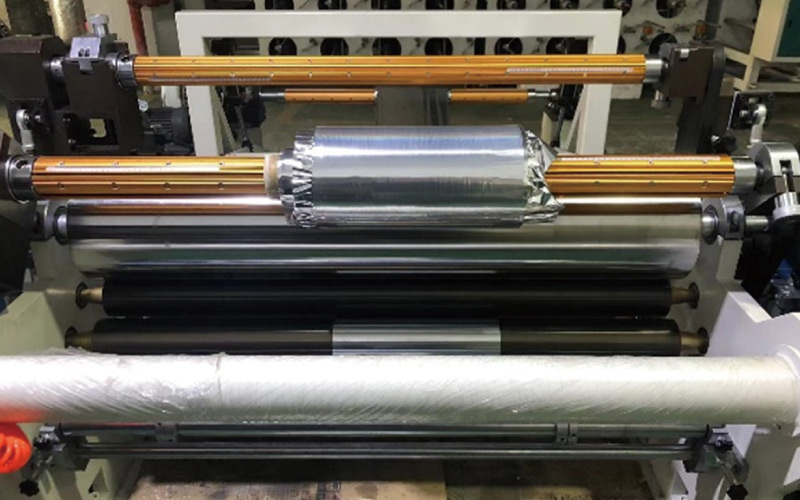

As society and technology continue to advance, the coating machine undergoes continuous improvement to meet the evolving demands of various industries. Playing a vital role in the physical manufacturing sector, coating machines are designed to apply precise layers of specific adhesives, paints, or inks onto the surfaces of materials such as film and paper, then dries and cuts them into sheets or rolls.

Features and Benefits

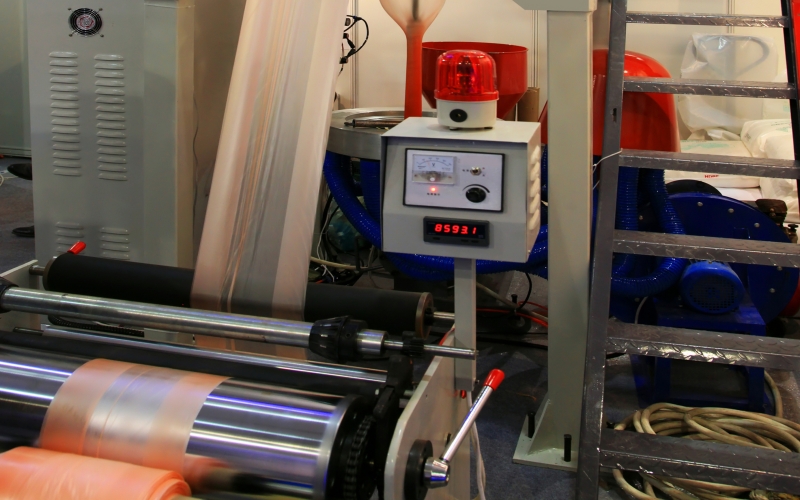

The VEICHI coating machine system solution offers high efficiency, stability, exceptional anti-interference capability, diverse functions, and broad applicability. It incorporates our VC5 motion controller, VC terminal expansion module, and AC310 highperformance AC drive to fulfill customer product requirements.

The system design includes multiple reversed debugging features, uses electronic gear synchronization for 10-axis linkage, and features PID auto-tuning tension output and accurate roll diameter calculation, reducing manual labor and significantly enhancing production efficiency.

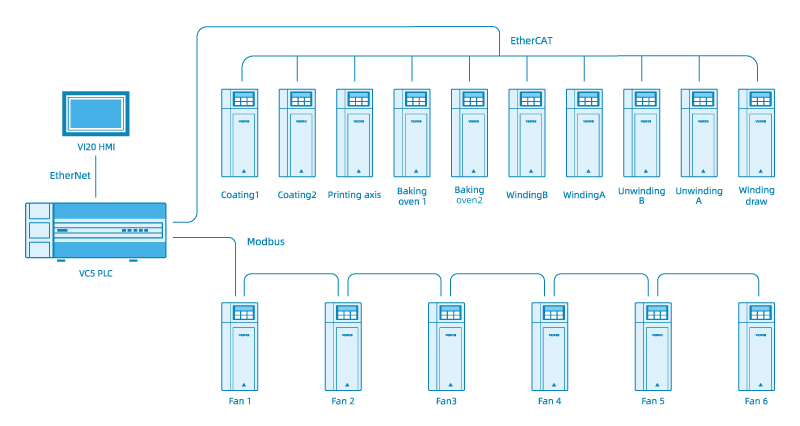

System Topology

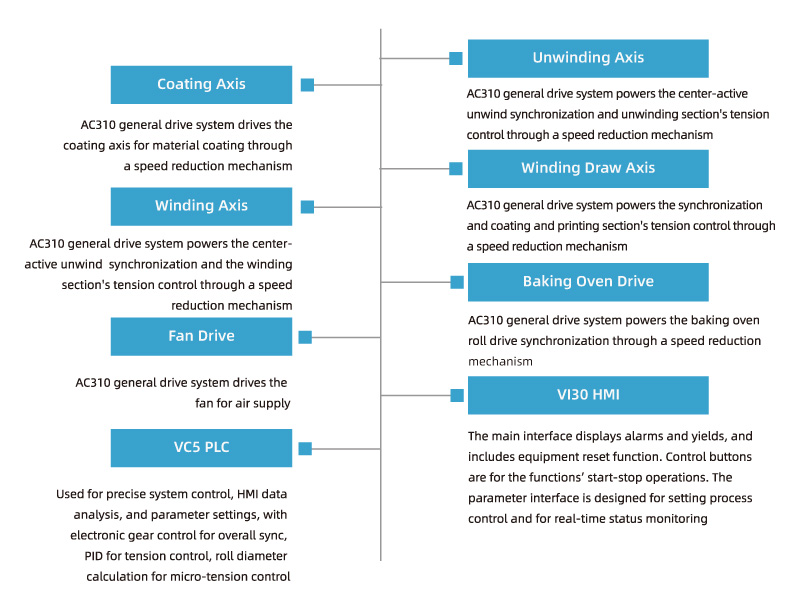

System Structure

Coating Axis: AC310 general drive system drives the coating axis for material coating through a speed reduction mechanism.

Winding Axis: AC310 general drive system powers the centeractive unwind synchronization and the winding section's tension control through a speed reduction mechanism.

Fan Drive: AC310 general drive system drives the fan for air supply.

VC5 PLC: Used for precise system control, HMI data analysis, and parameter settings, with electronic gear control for overall sync, PID for tension control, roll diameter calculation for micro-tension control.

Unwinding Axis: AC310 general drive system powers the center-active unwind synchronization and unwinding section's tension control through a speed reduction mechanism.

Winding Draw Axis: AC310 general drive system powers the synchronization and coating and printing section's tension control through a speed reduction mechanism.

Baking Oven Drive: AC310 general drive system powers the baking oven roll drive synchronization through a speed reduction mechanism.

VI30 HMI: The main interface displays alarms and yields, and includes equipment reset function. Control buttons are for the functions' start-stop operations. The parameter interface is designed for setting process control and for real-time status monitoring.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message