Edge Protection Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Edge Protection Machine Solution

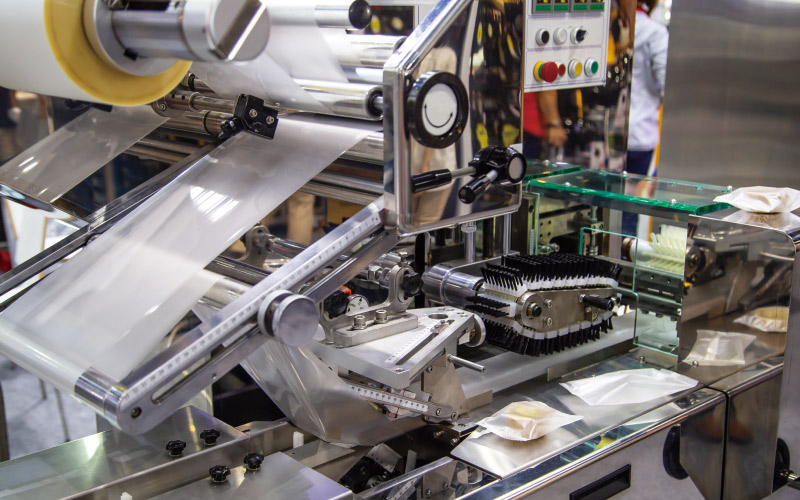

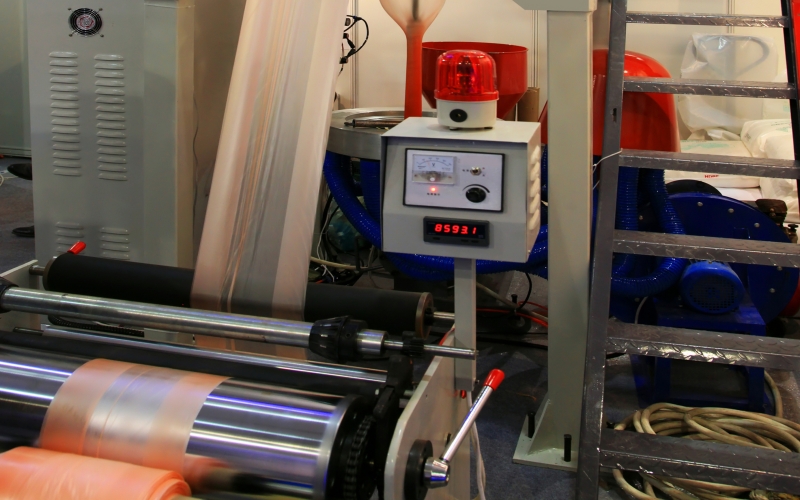

The edge protection machine, also known as paper angle bead maker, is widely used in packaging. VEICHI, responding to the growing need for automated equipment efficiency and precision, has created a faster edge protection machine that features order switching and deviation compensation, thereby achieving enhanced precision and speed over previous designs.

Features and Benefits

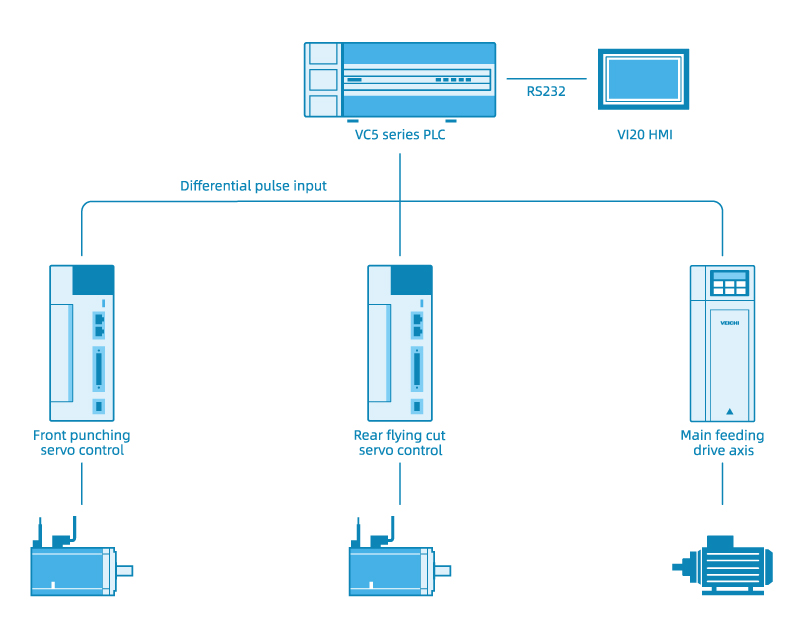

VEICHI excels in automation solutions, as seen in its edge protection machine application. Centralized around the VC5 motion controller, the system automates various stages including transmission, punching, cutting, and collection through smart control. It uses flying cutter cam and order switching technology to meet diverse production needs and employs compensation algorithms for process stability and consistency.

VEICHI's edge protection machine solutions offer high efficiency, stability, safety, and standout flexibility, delivering superior automated production to customers.

System Feature

System Integrity

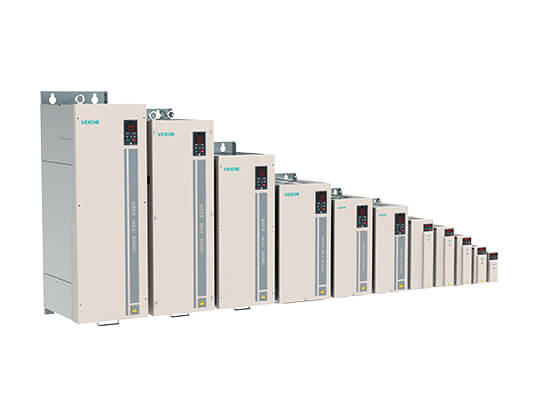

The system utilizes VEICHI's advanced automation products for its core components, enhancing the stability and compatibility of the control system, including motion controllers, servo drive, AC drive, and HMI. We also offer customers flexible solutions and prompt, reliable after-sales support.

Sophisticated System

The system is robust with complete protective logic, offering alarms and a timely stop function, as well as dual reminders from the HMI and indicator lights to ensure production safety. It also features a quantitative stop, fault self-detection, and enhanced logic protection. With multiple internal modes, it allows for easy switching, enhancing the equipment’s flexibility.

Quality Assurance

Various flying cut cam order switch and compensation algorithms are embedded internally to ensure qualified product yield.

High Efficiency

Production efficiency in length control mode and order switching mode is about 10% higher than that of competing products of the same type.

System Topology

System Structure

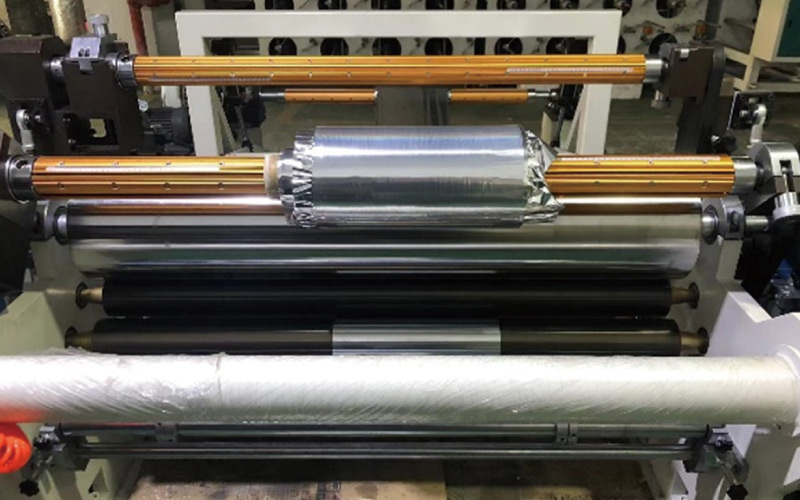

Conveying Section

The multi-axis press roller apply pressure along an extended guide rail during feeding to stabilize the punch and cutting process and maintain product specifications.

Punching Section

Process the feeding material for punching paper angle bead holes through coordinated changes in the flying cutter cam, hole count, and length settings, enabling swift spec adjustments for versatile processing with the rear cutting unit.

Cutting Section

Automated cutting accommodates various rear feeding orders for punching, with synchronized front-order switching and algorithmic compensation to ensure consistent setup and cut positions.

Receiving Section

Collect and store the shaped material via controlling the industrial-frequency motor and related cylinders.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message