High-Speed Kinking Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

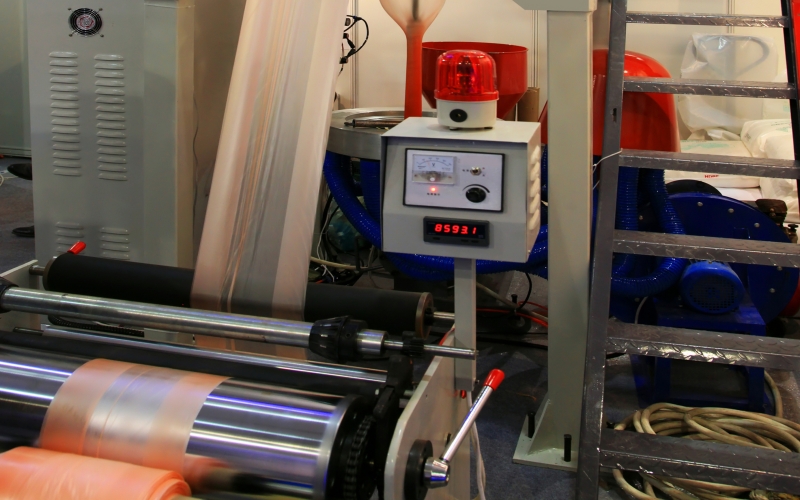

High-Speed Kinking Machine Solution

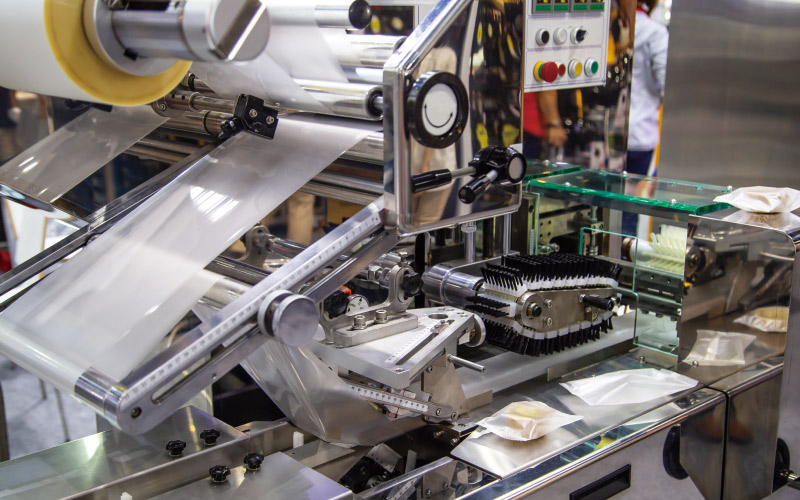

As food diversity grows with time, food machinery, especially for quick-serve items like sausages, evolves rapidly. VEICHI actively invests in the vital food industry, exemplified by the development of high-speed, dual-tube kinking machine.

Features and Benefits

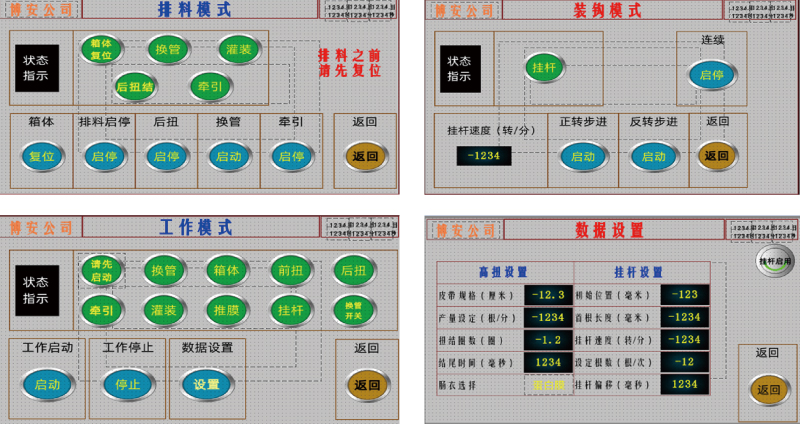

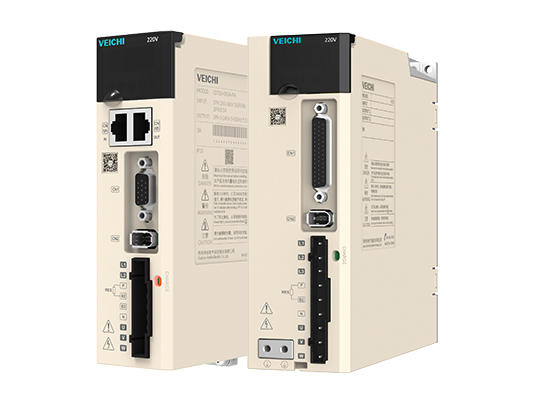

VEICHI high-speed, dual-tube kinking control system features efficient, stable, anti-interference performance and easy setup. The electronic control part adopts our proprietary products, including the VC5 bus motion controller, SD710 servo controller, and servo motors.

The high-speed kinking machine control system uses electronic cam synchronization for precise activation of the hanging rod. Synchronized torque control ensures stable filling, reducing casing breakage and downtime, thus enhancing production efficiency.

System Topology

VEICHI is actively advancing in the food machinery sector, having developed a high-speed double-tube sausage kinking machine solution. This solution incorporates the self-developed VC5 bus motion controller and SD710 bus servo drive, delivering accurate and efficient operation with speeds of up to 1,200 sausages per minute.

System Structure

Turntable Station

Driven by SD710, the station acts as a buffer for casing changes, quickly transitioning to stuff new casings through the turntable after the current sausage casing is filled.

Travel Station

Driven by SD710, the station is utilized for precise positioning. Once the travel axis reaches the working position, the machine begins filling and kinking.

Casing Extruding Station

Driven by SD710, the station is to extrude the sausage casing forward in order to make the filling more stable, and then feed the filled sausages out.

Front/Rear Kinking Station

Driven by the SD710, both stations should synchronize the kinking speeds at the front and back with the drawing speed to ensure sausages are kinked while being drawn out.

Draw Conveyor

Driven by the SD710, the station adjusts the draw axis frequency based on the set speed to convey filled sausages. Upon detecting a completed fill, it halts the conveyor precisely at the origin for accurate repositioning.

Hanging Rod Station

Driven by SD710, the hanging rod hangs up sausages based on set parameters once they are filled.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message