Auto Premade Bag Packaging Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

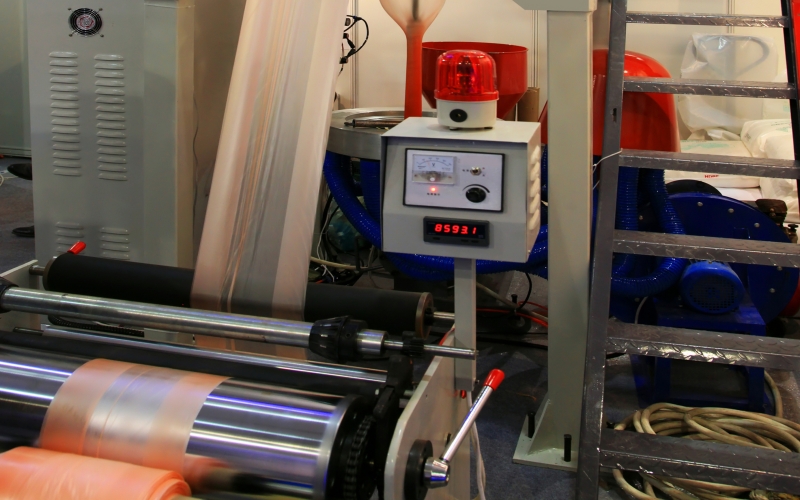

Auto Premade Bag Packaging Machine Solution

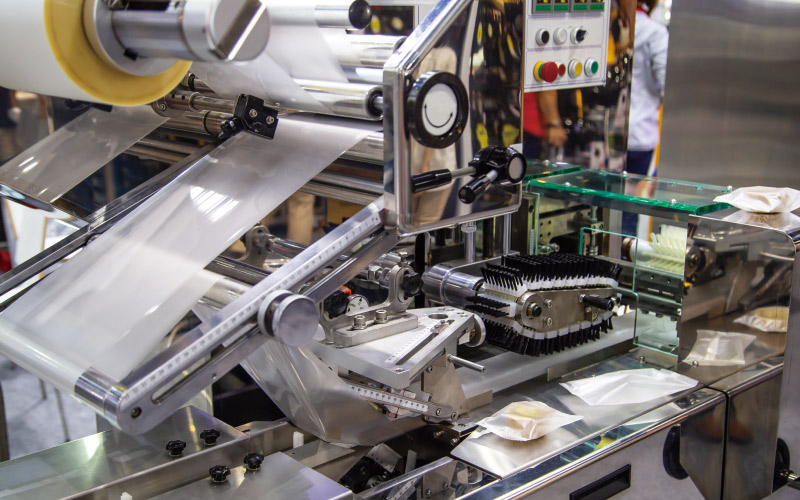

With advancing technology and automation levels, automated machinery has revolutionized the packaging industry, shifting from manual to automated machines to cut costs and boost efficiency. Premade bag packaging machines are now utilized across multiple sectors, including daily essentials, food, medicine, hardware, and agriculture, enhancing production efficiency, reducing expenses, and improving product quality..

Features and Benefits

The premade bag packaging machine control system boasts high efficiency, stability, robust anti-interference capabilities, a wealth of features, and broad applicability; it utilizes VEICHI VC5 bus programmable controllers, SD710EA servo controllers, servo motors, etc., fulfilling customer product requirements.

The system design features a range of reserved debugging options, flexible e-cam curve settings aligning with industry practices, and significantly enhances production efficiency for customers.

System Feature

Quality Assurance

The system's core components, including the PLC, servo parts, and HMI, are highperformance VEICHI automation products, ensuring superior stability, compatibility and flexibility. Moreover, VEICHI provides prompt, efficient after-sales service.

Sophisticated System

Featured with fault self-detection and logical protection, factory debugging mode, and multi-tiered password access for system administrators, managing personnel, and operators.

Fault Self-Detection

Identify servo drive faults and provide solutions, offer a fault stop function for program logic errors, and provide fault stop and alarm functions for incorrect

parameter settings whose ranges are limited, as well as functions such as element self-locking.

Extensive Functions

Automatic e-cam curve generation from key points offers user-friendly operation, a rich feature set, and high scalability.

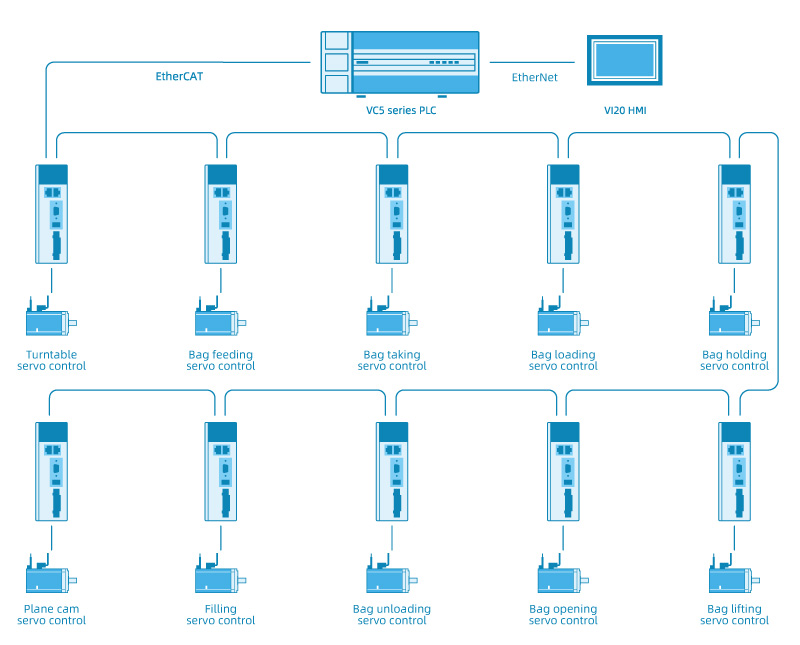

System Topology

VEICHI's new control system for bag packaging automates the entire process with their VC5 bus PLC and ten SD710 EtherCAT servo drives. It smoothly handles tasks such as carousel rotation and bag handling, filling, sealing, and more, delivering fast, accurate, and dependable packaging.

System Structure

8 stations correspond to 8 processes: bag taking, loading, reserved printing, opening and holding, filling 1, filling 2, empty bag detection, heat sealing 1, heat sealing 2 and unloading.

Bag Taking and Loading

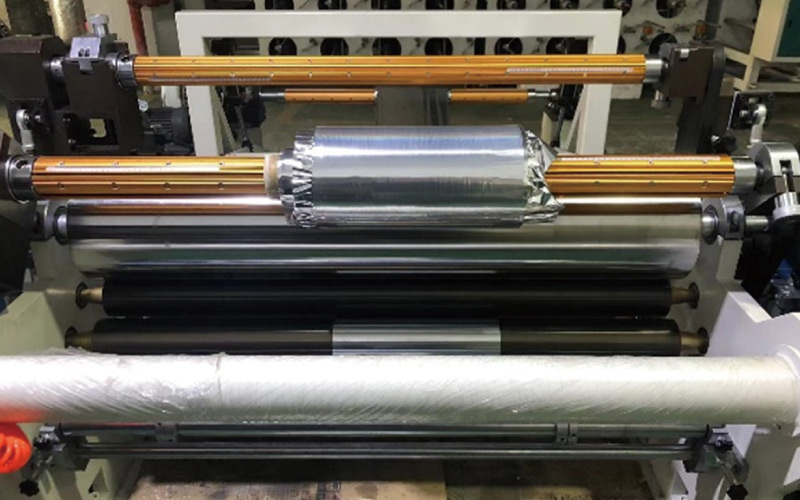

The staff places premade bags onto the loading station, where a servo-controlled vacuum suction system equipped with a de-static device continuously

picks up and transfers the bags. Servo control throughout the entire process, including bag taking, feeding, and loading, is linked to the spindle via preset electronic cam curves.

Filling 1

Feeding via the filling mechanism.

Heat Sealing 1

The heat-sealing controller regulates the temperature, and a stepper motor performs the sealing operation.

Reserved Printing Space

Space is reserved for adding date and time printers at a later stage.

Bag Opening and Holding

The bag-opening axis uses dual vacuum suction cups to open the bag from the side. The bag-lifting axis inserts the spreader bar into the opening to keep the bag open, moving in sync with the turntable. Only when the detection switch on the axis finds that the bag is open will the filling step proce.

Filling 2

Feeding via the filling mechanism.

Heat Sealing 1 and Unloading

Perform heat sealing again and the bag is unloaded via unloading servo control, and taken out via the conveyor belt.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message