Carbon Fiber Composite Material Production Line Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Carbon Fiber Composite Material Production Line Solution

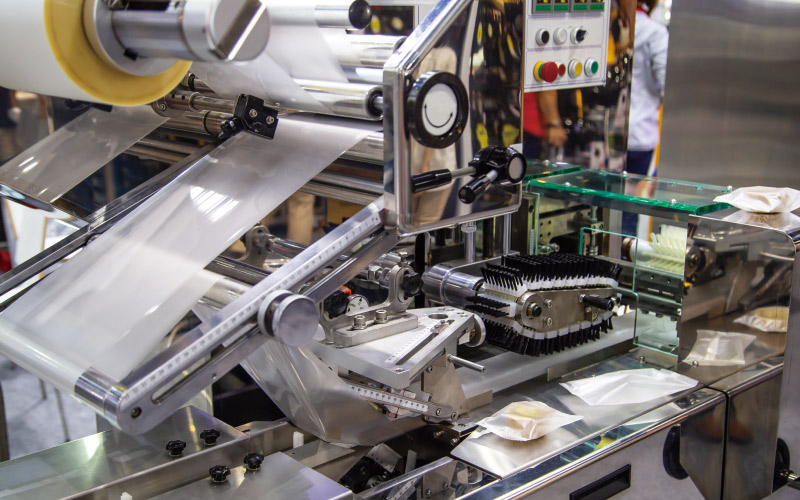

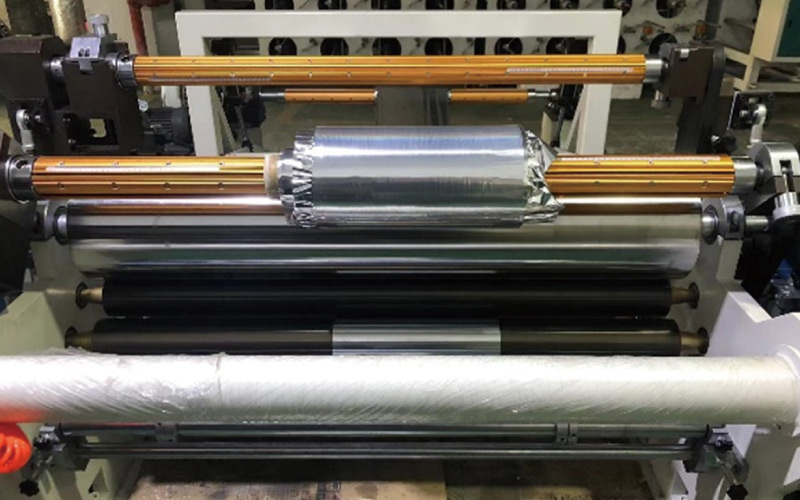

Carbon fiber is a new material known for being strong, tough, lightweight, and heat-resistant; it is widely used in industries such as wind power, cycling, fishing, aerospace, and automotive. Although it is generally applied in industries, carbon fiber can't be immediate used upon production. It must be spread onto fabric, covered with film, heated, and then extruded to create the final product for use in various applications.

VEICHI has developed a complete servo-driven system solution for producing carbon fiber composites, which aims to address specific challenges in the electrical market.

Features and Benefits

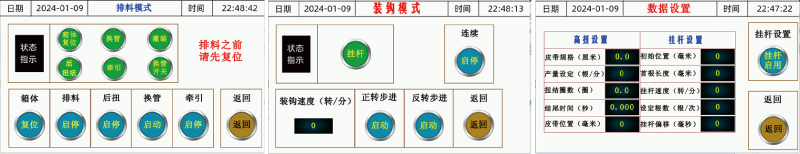

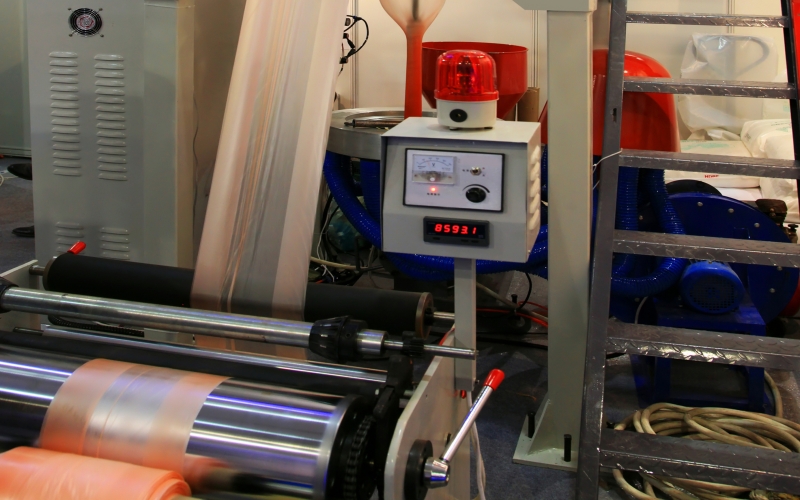

The VEICHI carbon fiber composite material production line solution offers efficient, stable, and easily configurable control with strong anti-interference and diverse functions. The control system features in-house developed PLCs, servo drives, AC drives, and motors, catering to various customer requirements.

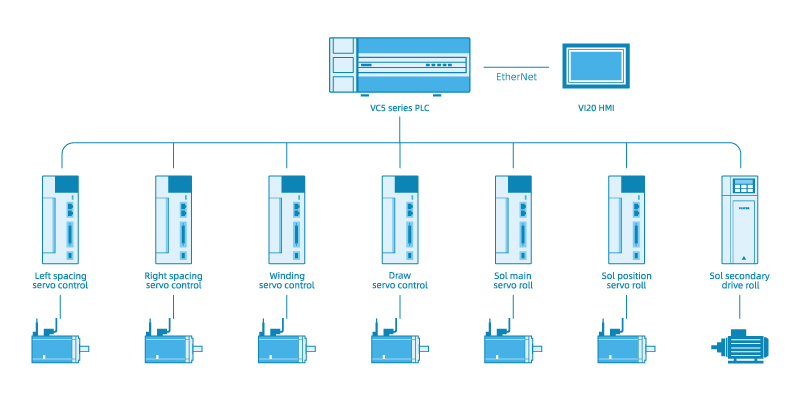

System Topology

The VC5 controller, serving as the core of the control system, features a dual-core FPGA+ARM setup and supports up to eightaxis pulse output. With capabilities like EtherCAT, electronic cam, and interpolation, it provides cost-effective performance for sectors like machining, textiles, packaging, plastics, steel, and medical. The system also boasts EtherCAT to control the SD700EA bus servo for improved efficiency and smooth control.

Global - English

Global - English Spanish - Español

Spanish - Español Arabic - عربي

Arabic - عربي Italian - Italiano

Italian - Italiano Polish - Polski

Polish - Polski French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Ukrainian - українська

Ukrainian - українська Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Turkish - Türkçe

Turkish - Türkçe Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message